Micro and Nanotechnology

There’s a big future in small things. Nanotechnology is the new frontier of engineering, imagining new possibilities in manufacturing, fluid mechanics, robotics, combustion, biomedicine, measurements, heat transfer, and more. Purdue hosts the largest academic cleanroom in the world, the Birck Nanotechnology Center , where interdisciplinary teams have access to the absolute cutting-edge of nano-scale characterization (microscopy and measurements) and fabrication (deposition, etching, lithography, etc.) With these tools, mechanical engineers conduct world-class research in:

Nanoscale manufacturing

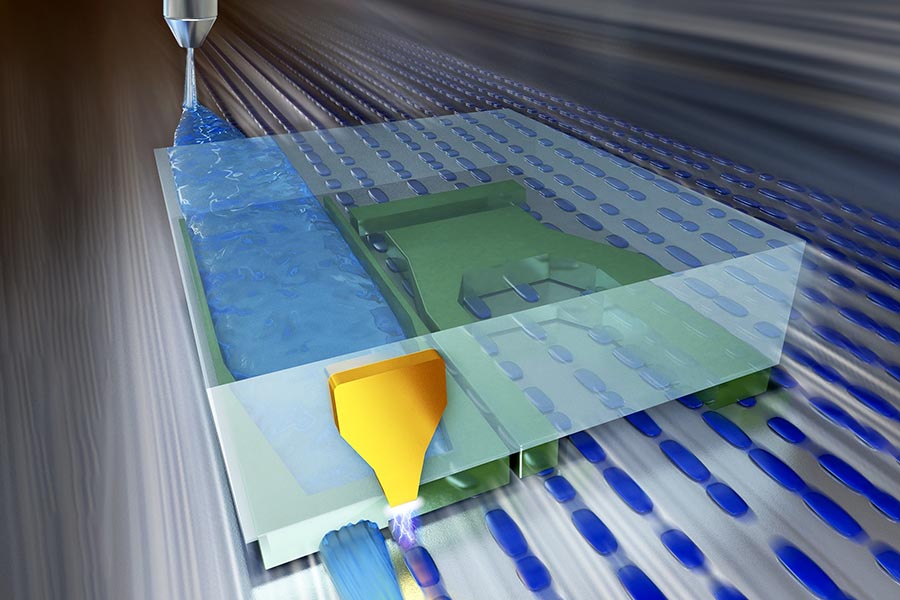

Micro- and nano-fluidics

Biomolecular detection

Nanoscale thermal transport

Computational modeling

Nanomechanical materials

Faculty in Micro & Nanotechnology

Fluid dynamics

Biomaterial

Multiphase flows

Non-Newtonian fluid dynamics

Microfluidics

Complex fluids

Soft matter

Modeling of nonlinear systems

Structural dynamics and localization

Flow-induced vibrations

Impacting systems

Bifurcations and chaos

Renewable Energy Materials (physics-based energy yield predictions, sustainable PV and energy storage materials, recycling)

Electro-Optical-Thermo-Mechanical Reliability (in-situ and in-operando accelerated stress tests)

Heterogeneous Integration & Advanced Packaging (sub-10 μm pitch interconnects, low-loss interposers)

Harsh Environment Electronics Integration (high temperature Pb-free solders and nano-thermal interfaces)

Thermal Physics ... Heat Moving Energy

Spectroscopy ... "Seeing" energy with light

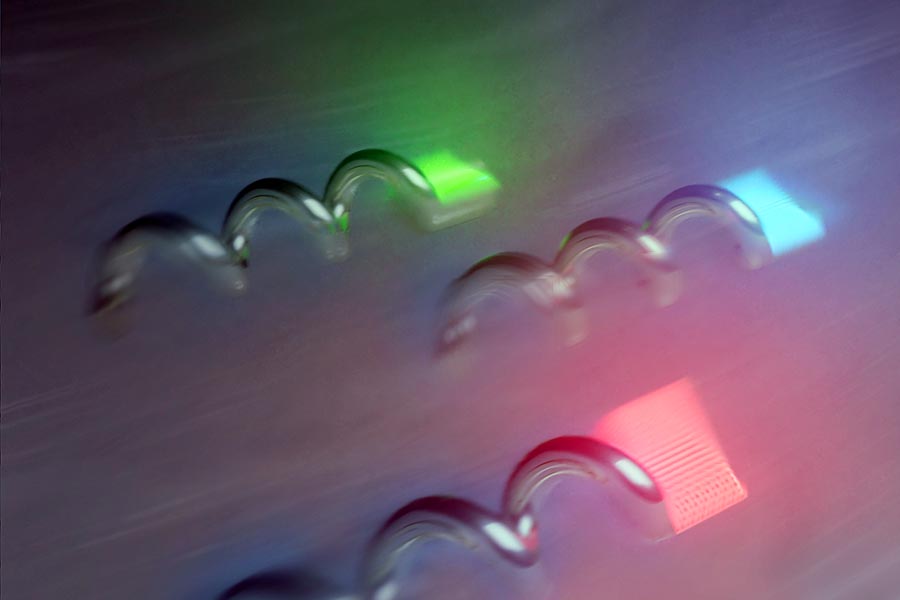

Nanophotonics ... Pushing light to see more

2D Materials ... Creating functionality by losing dimension

Modeling and experimental studies on processing

Structure property relationships in polymer films and moldings and polymer/metal/ceramic hybrid systems

Multi-scale robotic manipulation and assembly

Mobile micro/nano robotics

Micro/nano aerial vehicles

Micro-Bio robotics

Mechatronics

MEMS/NEMS

Automation for the life sciences

Dynamic systems and control

Mechatronics

Digital and functional printing and fabrication

Motion and vibration control and perception

Embedded systems and real-time control

Advanced materials

Bioinspired design and manufacturing

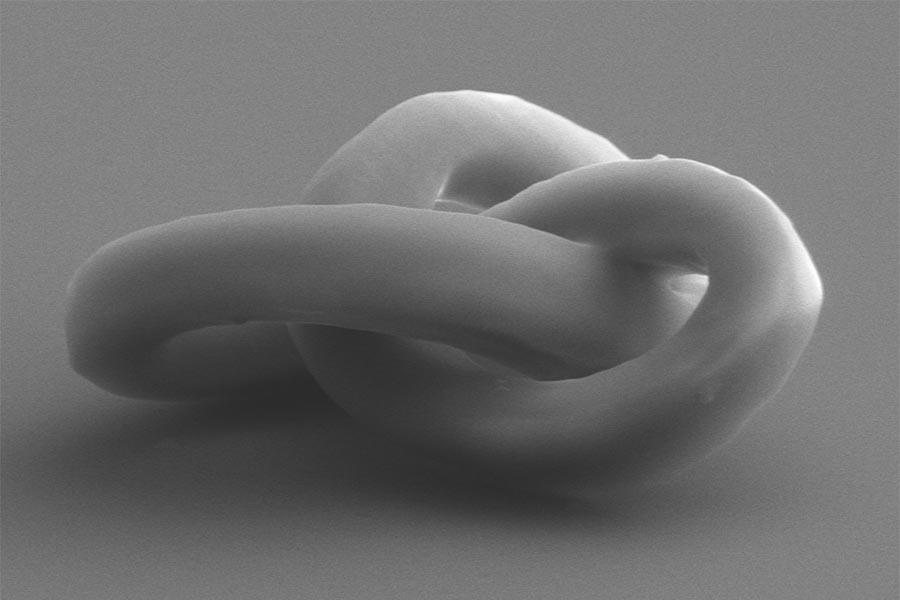

Nanomachines

Bio-inspired and mechanically adaptive electronics

Multimaterial additive fabrication

Soft actuators (artificial muscles)

Wearable actuators (haptics)

Polymer design and polymer physics

Deformation sensors and transistors

Soft hydraulics

Fluid dynamics

Non-Newtonian fluid mechanics

Particulate and multiphase processes

Computational and data-enabled science & engineering

Scientific machine learning

Nonlinear waves

Composites materials design and manufacturing

Sustainable and recyclable-by-design polymers and composites

Polymer processing and characterization

Composites recycling

Hybrid manufacturing systems

Multiscale modeling

Damage mechanics

Laser absorption spectroscopy diagnostics for gas temperature, pressure, velocity, and chemical species

Laser-induced fluorescence and photophysics

Non-equilibrium gases and reaction kinetics

Hypersonic flows, shock waves, and detonation waves

Combustion and propulsion

Predictive, multi-scale modeling and simulation of microstructure evolution in confined granular systems, with an emphasis in manufacturing processes and the relationship between product fabrication and performance.

Application areas of interest include:

(i) particulate products and processes (e.g., flow, mixing, segregation, consolidation, and compaction of powders),

(ii) continuous manufacturing (e.g., Quality by Design, model predictive control, and reduced order models), and

(iii) performance of pharmaceutical solid products (e.g., tensile strength, stiffness, swelling and disintegration), biomaterials (e.g., transport and feeding of corn stover) and energetic materials (e.g., deformation and heat generation under quasi-static, near-resonant and impact conditions, and formation and growth of hot spots) materials.

Sustainable energy and environment

Combustion and turbulent reacting flows

Combustion and heat transfer in materials

Biomedical flows and heat transfer

Global policy research

Advanced multi-scale manufacturing

Ultrafast laser machining and processing

Fiber optic sensors and environmental monitoring

Spray-based nanoparticle coating and additive manufacturing

Machining of carbon fiber reinforced polymer (CFRP) composites

Computational solid mechanics

Multiscale modeling of materials

Finite Elements

Dislocation dynamics

Reliability of electronic interconnects

Shock compression in solids

Phase transformations

Energetic materials

Wearable biomedical devices

'Crack’-driven transfer printing technology

Scalable manufacturing technology

Mechanics and materials for flexible/stretchable electronics

Optical tweezers and optical manipulation

Nanophotonics

Photothermal conversion and applications

Optical and optoelectronic materials

Nanoscale energy transfer

Laser processing and diagnosis

Acoustic tweezers

Acoustofluidics

Acoustic metamaterials

Ultrasound control

Underwater communication

Ultrasound imaging

Multiphysics wave propagation theory

Noise control and energy harvesting

Naturally nanostructured materials

Energy, water, and wearable technology

Manufacturing

Bio-inspired designs

Surface engineering and multifunctional materials

Convergent Manufacturing for Industry 5.0: hybrid manufacturing processes, heterogeneous materials, and bio-inspired designs

Systems integration, productization, and production

Heavy-duty machines: machining, lubrication, and corrosion

Heterogeneous and hierarchical integration (mechanical-electrical-optical and nano-micro-meso-macro)

Precision agricultural and food: cellular agriculture, vertical farming, micro-production, and resilience

Frugal engineering, social innovations, and social equity

Manufacturing in space

Transport Phenomena in Multi-Scale, Heterogeneous Materials & Systems

Fundamentals of Nanoscale Thermal Transport

Heat Transfer in Natural and Synthetic Fiber Systems

Thermofluids Interactions

Multi-Physics Metrology Design

Electronics Cooling and Thermal Management

Energy storage and conversion (batteries, fuel cells)

Mesoscale physics and stochastics

Reactive transport, materials, processing, and microstructure interactions

Scalable nanomanufacturing: lithography and imaging

Optical and magnetic data storage

Nanoscale energy conversion, transfer and storage for alternative energy

Mechanobiology and biomechanics

Diagnostics

Bacterial biophysics

Micro/nano fluidics and transport

Biotechnology development

Physicochemical hydrodynamics

Measurement tools

Biomedical devices and wearables

Simulations of nanoscale thermal transport

Machine learning, optimization, and high throughput design

Thermal management in electronics, space, and battery applications

Transport phenomena in additive manufacturing

Nanomaterials and devices for sustainable energy

Contact mechanics

Stresses, fatigue and friction of rolling/sliding

Micro-mechanics of boundary and mixed lubrication regimes

Spall initiation and propagation

Surface science and damage

Dynamics of ball and rolling element bearings and rotating systems

Friction induced vibration and squeal in dry contacts

Friction and wear of dry and lubricated contacts

Virtual tribology

Dry and lubricated fretting wear

MEMS for in-situ monitoring of tribological contacts

Discrete element modeling

Design

MEMS, nanotechnology

BioMEMS

Biosensors

Protein detection

Aptamers (Nucleic-acid-based receptor molecules)

Laser additive manufacturing

Ultrafast laser matter interaction

Laser welding

Laser assisted machining

Laser shock peening

Multi-physics, multi-scale modeling

Micro-nano manufacturing

Multiphase combustion, particularly related to propellants, explosives, and pyrotechnics

Nanoscale composite energetic materials

Advanced energetic materials

Microscale combustion

Computational and experimental solid mechanics focused on fatigue, fracture, and multi-physics phase evolution problems

Computational techniques including Finite Element Analysis (FEA), Isogeometric Analysis (IGA), geometric modeling, CAD and optimal design

Heterogeneous Integration and Advanced Electronics Packaging with a focus on thermomechanical behavior, reliability, and electrical-thermal-mechanical co-design

Measurement science and instrumentation

Particle image velocimetry

Quantification of uncertainty

Multi-phase flows

Flow induced vibrations and hydro-kinetic energy

Biological flows

Biofluid mechanics

Biomedical cardiovascular devices

Heart failure and diastolic dysfunction

Scanning Probe Microscopy

Metrology

Optomechanics

Mass spectrometry

Contact mechanics

Desalination & Water Treatment

Water-Food-Energy Nexus

Thermofluids

Nanotechnology

Membrane Science

Discrete element method (DEM) modeling for particulate systems

-- model development, e.g., fibrous particles, particle breakage, particle shapes

-- application to manufacturing, e.g., storage and flow, blending, segregation, drying, coating, wet granulation

Finite element method (FEM) modeling of powder compaction

-- e.g., roll compaction, tableting, picking and sticking

Multi-scale modeling (FEM combined with DEM) of powder dynamics

-- model development and application to hopper flow, blending, and segregation

Advanced electronics cooling and packaging technologies

Phase-change transport phenomena

Additive manufacturing of thermal management components

Topological optimization and machine-learning-based design

Thermal systems analysis for electrification and energy efficiency

Microscale and nanoscale surface engineering for enhanced thermal transport

Laser-matter interactions

Laser-induced plasma and laser-plasma interaction

Laser applications in manufacturing, materials processing, and other areas

Nanoscale energy transport

Nano-optics and laser-based nano-optical engineering

Image-based computational and experimental fluid dynamics for porous-media and biomedical flows

Translational research integrating high-performance CFD, image-based and physics-informed machine-learning, and uncertainty quantification to address unmet clinical needs

GPU-parallelized lattice Boltzmann method for DNS and LES of turbulence

Micro-bubble coalescence and detachment in microfluidics

Biomanufacturing and biopreservation

Microfluidics

Biotransport

Micro/nano biomedical devices

Diagnostics

Multiscale superfast 3D optical sensing

Biophotonic imaging

Optical metrology

Machine/computer vision

3D video telepresence

3D video processing

Virtual reality

Human computer interaction

Deformation, stress, plasticity, fracture

Multiscale modeling, first-principles, molecular dynamics simulations, and finite element modeling

In-situ experiments

Mechanics of redox active materials - Li-ion batteries, Na-ion batteries, all-solid-state batteries

Mechanics of polymeric materials - organic electrochromics, superelastic organic semiconductors

Lithium-ion batteries

Solid-state batteries

In situ and operando characterization

Modeling, simulation, and optimization of battery systems

Micro/nano fabrication

Micro/nano fluidics

I want to research in

I want to have an impact in...