Heat & Mass Transfer

Heat & Mass Transfer impacts nearly every area of industry, which is why Purdue hosts numerous laboratories dedicated to studying, enhancing, and pioneering new methods of heat transfer and energy conversion. With this research, Purdue is answering the challenging questions:

- How will we cool the avionics of future spacecraft?

- What can make solar-powered energy more feasible?

- Where does heat transfer improve on engine or battery performance?

- How can nanomanufacturing create better electronics?

- Can thermal therapy create new treatments for disease?

Faculty in Heat & Mass Transfer

- Modeling, Experiments and Simulations of turbulent boundary layers: role of initial conditions and bio-inspired micro-surfaces on evolution of velocity/thermal fields.

- Importance of turbulence and complex topography on wind energy.

- Integration of renewable with water and thermal storage.

- Translational research focus on renewable energy & society

- Wall interaction (e.g., bio-inspired micro surfaces) in respiratory flows

- Big data in turbulence, renewable energy and biomedical engineering.

- Energy and social equality

- Computational and experimental solid mechanics focused on fatigue, fracture, and multi-physics phase evolution problems

- Computational techniques including Finite Element Analysis (FEA), Isogeometric Analysis (IGA), geometric modeling, CAD and optimal design

- Heterogeneous Integration and Advanced Electronics Packaging with a focus on thermomechanical behavior, reliability, and electrical-thermal-mechanical co-design

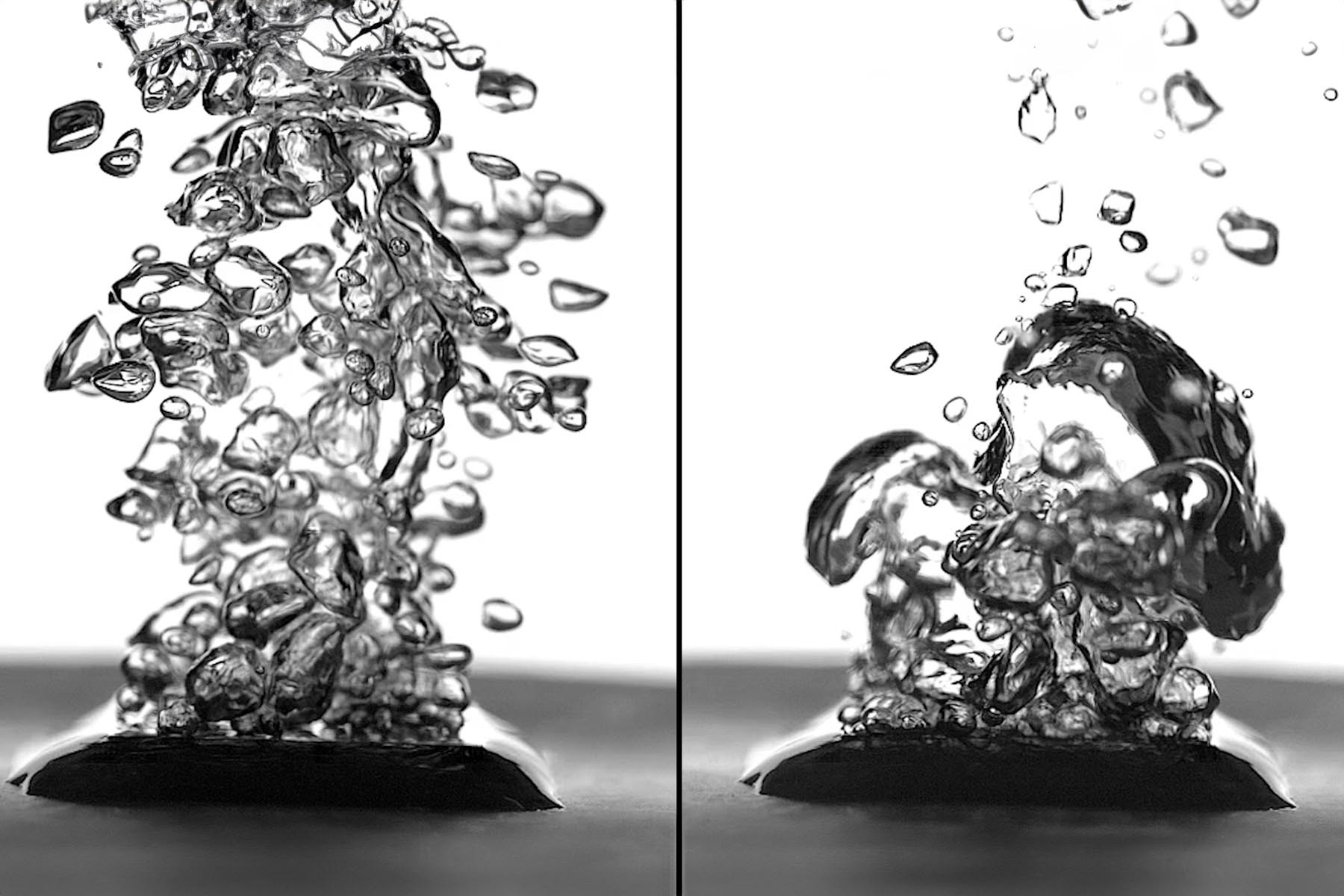

- Two-Phase Flows and Heat Transfer

- High-Heat-Flux Thermal Management Systems for Several Applications, e.g., Outer Space Missions, Electric Vehicles, Ultra-Fast Charging Systems, Electronics Cooling, Avionics, Nuclear Reactors, Metal Manufacturing, Superconductors, Data Centers, etc.

- Gravitational Effects

- Experiments onboard the International Space Station (ISS)

- Two-Phase Flow Instabilities

- Fluid-Structure Interactions & Non-Newtonian Fluids in Biological Systems

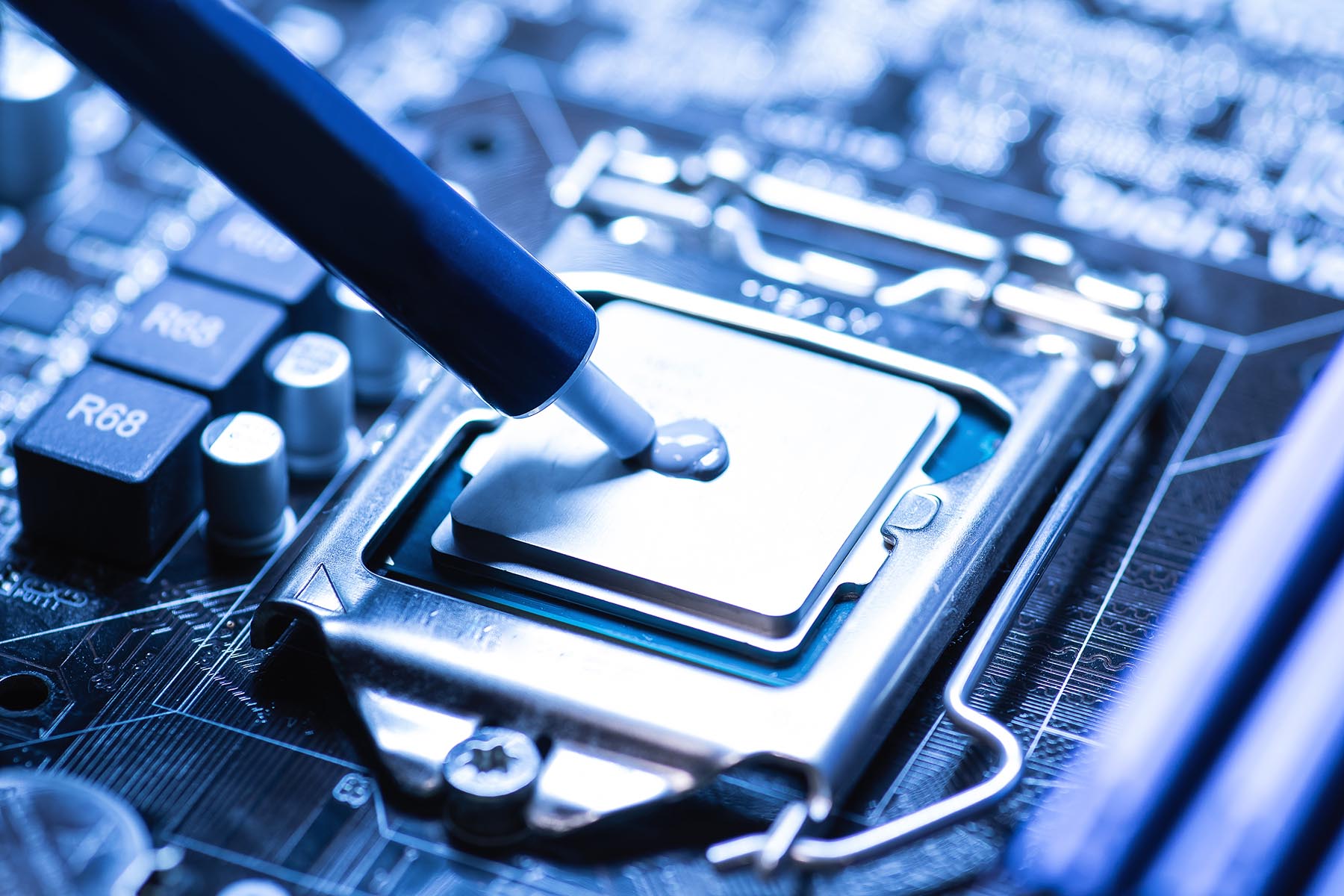

- Advanced electronics cooling and packaging technologies

- Phase-change transport phenomena

- Additive manufacturing of thermal management components

- Topological optimization and machine-learning-based design

- Thermal systems analysis for electrification and energy efficiency

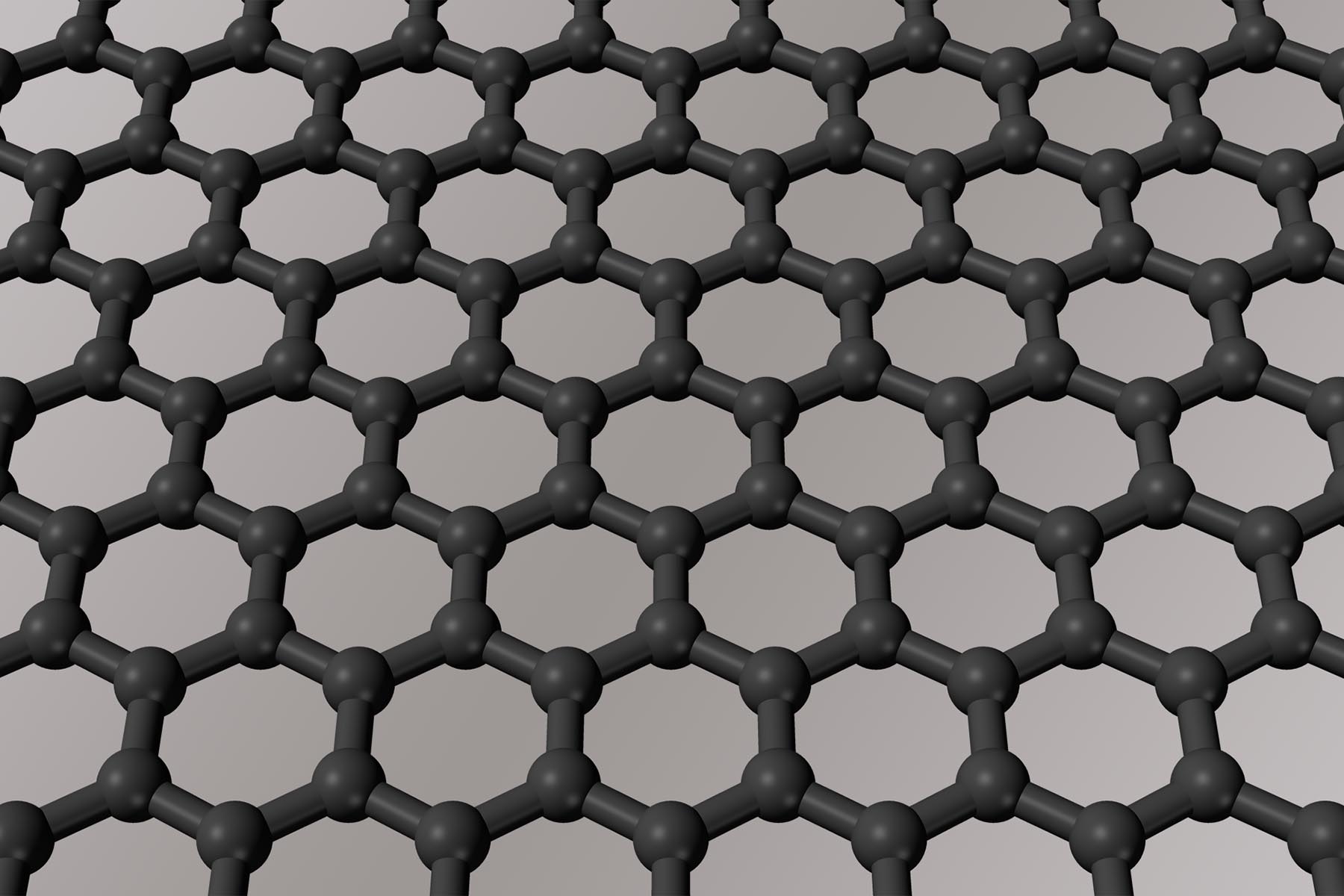

- Microscale and nanoscale surface engineering for enhanced thermal transport