Particles & Powders

Particles and powders are everywhere -- from the food we eat, to the medicines we take, to the products we use and the roads we drive on. And no one knows particles like Purdue! The Center for Particulate Products and Processes (CP3) is the foremost particle science lab in the country, with testbeds found nowhere else in academia. CP3 combines the best of academia with the best of industry, to advance the science of particles, powders, and compacts. World-class research facilities enable advancements in manufacturing, agriculture, pharmaceuticals, food science, energetic materials, and more!

Faculty in Particles & Powders

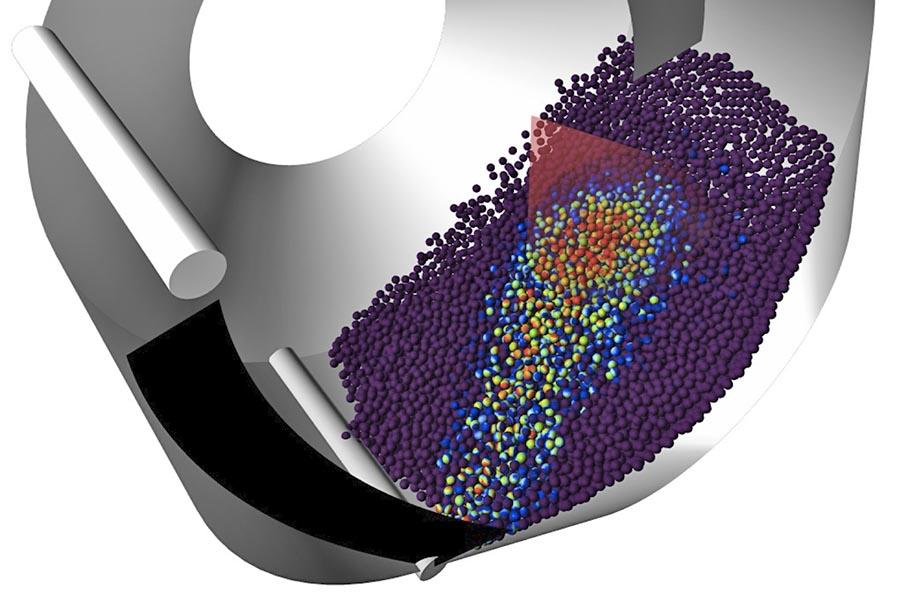

- Predictive, multi-scale modeling and simulation of microstructure evolution in confined granular systems, with an emphasis in manufacturing processes and the relationship between product fabrication and performance.

- Application areas of interest include:

- (i) particulate products and processes (e.g., flow, mixing, segregation, consolidation, and compaction of powders),

- (ii) continuous manufacturing (e.g., Quality by Design, model predictive control, and reduced order models), and

- (iii) performance of pharmaceutical solid products (e.g., tensile strength, stiffness, swelling and disintegration), biomaterials (e.g., transport and feeding of corn stover) and energetic materials (e.g., deformation and heat generation under quasi-static, near-resonant and impact conditions, and formation and growth of hot spots) materials.

- Discrete element method (DEM) modeling for particulate systems

- -- model development, e.g., fibrous particles, particle breakage, particle shapes

- -- application to manufacturing, e.g., storage and flow, blending, segregation, drying, coating, wet granulation

- Finite element method (FEM) modeling of powder compaction

- -- e.g., roll compaction, tableting, picking and sticking

- Multi-scale modeling (FEM combined with DEM) of powder dynamics

- -- model development and application to hopper flow, blending, and segregation