Fastest ever nano-pen "surfs" on a liquid cushion

As computer technology continues to shrink, researchers rely on nanolithography to create the next generation of computer processors, nano-robots, and other very small manufactured items. But despite their small size, creating the fine details required by scanning probe lithography actually takes a long time.

"We are writing lines that are a thousand times thinner than a human hair," said Bojing Yao, a PhD student in the lab of Liang Pan, associate professor of mechanical engineering. "But we are still writing these patterns one line at a time. To make SPL feasible for manufacturing, we have to make it faster."

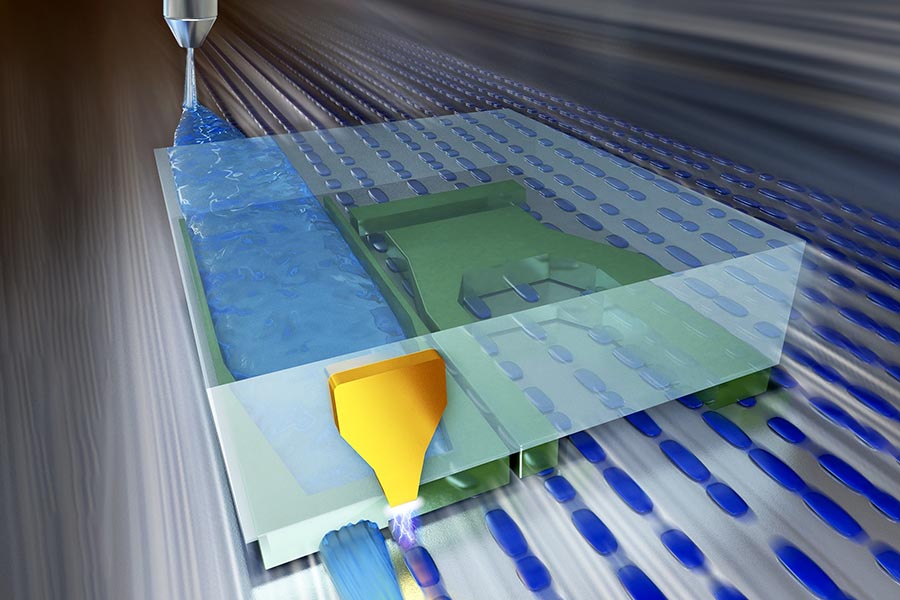

Yao took his cues from an existing technology: hard disk drives. "The metallic platter of a disk drive spins very fast on a cushion of air," said Yao. "We took this idea, but added a liquid bearing, so the print head 'surfs' on a thin layer of liquid ink."

Their research has been published in Nano Letters.

The liquid is delivered through a microchannel embedded into the print head. The nano-pen floats 2 microns above the surface, delivering a small electric charge to bond a portion of the ink to the surface. As the head floats away, the excess ink evaporates, leaving just the desired pattern. Yao manufactured the print head at Birck Nanotechnology Center.

The numbers behind this new method are staggering. The probe can print up to 20 million dots per second. And while most SPL print heads travel at centimeters per second, this nano-pen can travel up to 10 meters per second – more than 22 miles per hour! "If we scale it up," said Yao, "that would be like a Boeing 747 flying just one millimeter off the ground!"

It's so fast and so small, that there aren't cameras capable of filming the actual printing process. And for now, the team has only demonstrated it with one print head, printing a single pattern of dots and lines. In the future, the team is planning on arranging hundreds of nano-pens in parallel on a single print head, to increase the throughput even more.

But the printed results speak for themselves. "This technology has many future uses," said Pan. "It could fabricate future data storage devices or semiconductor chips. As a direct-write method, it also has niche applications, such as fabrications of photomasks for photolithography and masters for nanoimprint lithography.”

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Source: Liang Pan, liangpan@purdue.edu, 765-496-2341

Surfing Scanning Probe Nanolithography at Meters Per Second

Bojing Yao, Chen Chen, Zhidong Du, Qian Qian, and Liang Pan

https://doi.org/10.1021/acs.nanolett.1c03705