Protecting hypersonic vehicles with nanomaterials

“MXenes are part of a family of 2D materials,” said Babak Anasori, Reilly Rising Star Associate Professor of Materials and Mechanical Engineering. “You may have heard of graphene, which is made from a layer of carbon just one-atom thick. MXenes are few-atom-thick 2D sheets made of layers of metals and carbon, and these structures demonstrate new and incredible properties.”

First discovered in 2011, MXenes have a wide range of potential uses, from batteries to sensors to biomedical applications. In Anasori’s lab in Indianapolis, they are focusing on a new application: the construction of ceramic materials capable of handling immense amounts of heat, as you might find on the surface of a potential hypersonic vehicle.

But first, you have to make the things.

“Synthesizing MXenes is quite different than other 2D materials,” said Brian Wyatt, a Purdue Ph.D. student in Indianapolis who works in Anasori’s lab. “Rather than other 2D materials which are built up atom-by-atom from reactive gases, we make MXenes by taking an existing 3D material and stripping away layers until we have the few-atom thick material we want.”

The team uses harsh chemicals like hydrofluoric acid to break chemical bonds and delaminate the few-atom-thick layers, leaving just the desired materials. But unfortunately, this process can also leave something else in the MXene: holes.

“Through electron microscopy and other methods, we’ve observed many transition metal defects in the surface of the MXenes when making this material,” Wyatt said. “Because these materials are so small, when even the tiniest part of the MXene flakes away, it leaves an imperfect defective surface which significantly affects its stability. Every atom matters.”

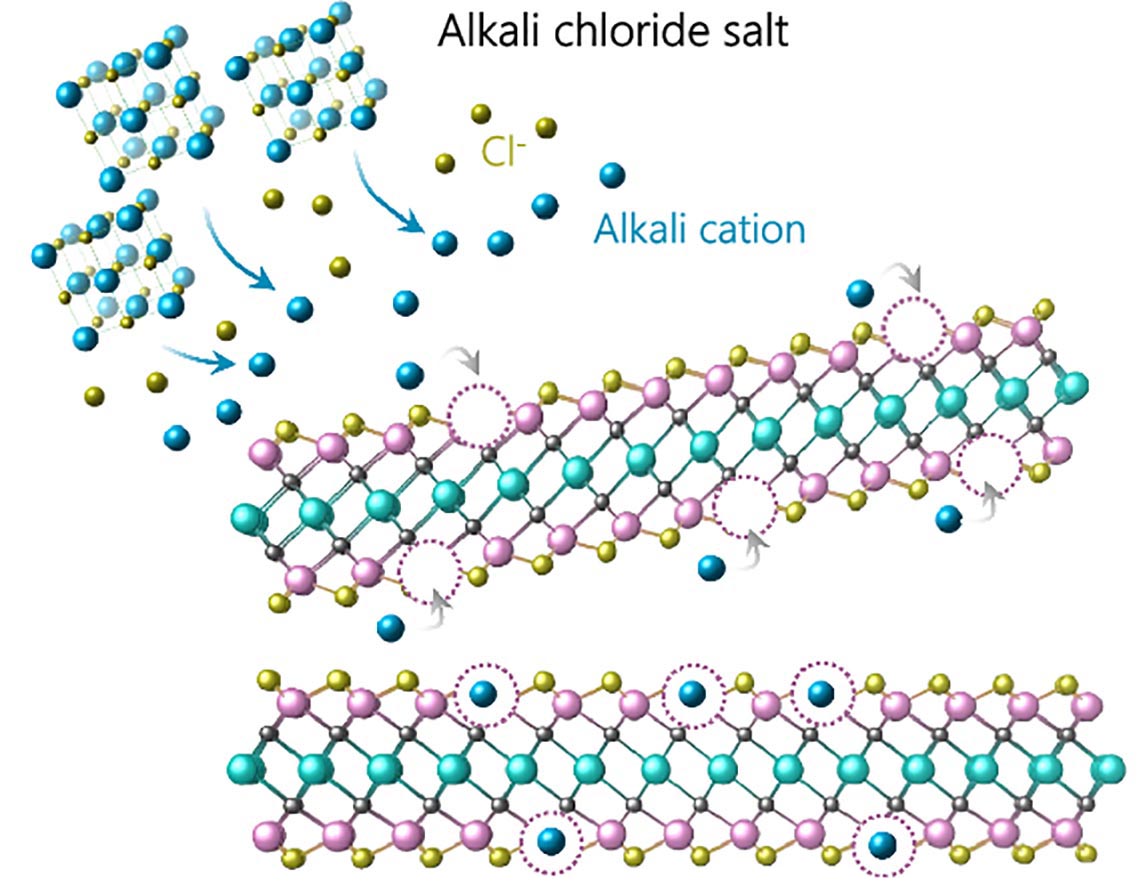

In a new paper published by Nature Communications, Anasori’s team have demonstrated that incorporating simple salts into the manufacturing process serves to fill in the holes caused by the acid etching process.

“Normally after we make MXenes, we have them suspended as single flakes in water,” Wyatt said. “We discovered that adding simple table salt (sodium chloride) can cause single sodium atoms to go into those defective holes. As a result, the alkali cations are capable of stabilizing the 2D material, even at 1,600 degrees Fahrenheit.”

It’s those high temperatures which MXenes can operate in that caught the attention of the Office of Naval Research (ONR), who are working on developing next-generation hypersonic vehicles. At high speeds, the compression of air creates tremendous amounts of heat and pressure on the surface of a hypersonic vehicle, which requires advances in material science to properly manage.

“We are the first research group in the country that are investigating MXenes for use in hypersonics,” said Anasori. “Using 2D materials gives us tremendous freedom to design new structures atom by atom and layer by layer that can withstand high temperatures.”

Purdue University has demonstrated its leadership in the hypersonics field with world-class facilities and interdisciplinary collaborations. They recently opened a groundbreaking $41 million Hypersonics and Applied Research Facility (HARF), hosting hypersonic shock tunnels that can simulate conditions up to Mach 40.

While Anasori’s work is still at the fundamental scientific stage, he can envision a future where a thin coating of MXenes can be sprayed on to existing materials like a paint, making those materials incredibly resistant to heat and oxidation.

“We believe that focusing on engineering these ceramics at the atomic level will enable much more high-performance materials,” said Anasori. “The key to success is focusing on one nanometer at a time.”

This research is funded by the Office of Naval Research (ONR) under award number 014-21-1-2799.

Source: Babak Anasori, banasori@purdue.edu

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Alkali cation stabilization of defects in 2D MXenes at ambient and elevated temperatures

Brian C. Wyatt, Matthew G. Boebinger, Zachary D. Hood, Shiba Adhikari, Pawe Piotr Michaowski, Srinivasa Kartik Nemani, Murali Gopal Muraleedharan, Annabelle Bedford, Wyatt J. Highland, Paul R. C. Kent, Raymond R. Unocic, Babak Anasori

https://doi.org/10.1038/s41467-024-50713-2

ABSTRACT: Transition metal carbides have been adopted in energy storage, conversion, and extreme environment applications. Advancements in their 2D counterparts, known as MXenes, enable the design of unique structures at the ~1 nm thickness scale. Alkali cations have been essential in MXenes manufacturing processing, storage, and applications, however, exact interactions of these cations with MXenes are not fully understood. In this study, using Ti3C2Tx, Mo2TiC2Tx, and Mo2Ti2C3Tx MXenes, we present how transition metal vacancy sites are occupied by alkali cations, and their effect on MXene structure stabilization to control MXene’s phase transition. We examine this behavior using in situ high-temperature x-ray diffraction and scanning transmission electron microscopy, ex situ techniques such as atomic-layer resolution secondary ion mass spectrometry, and density functional theory simulations. In MXenes, this represents an advance in fundamentals of cation interactions on their 2D basal planes for MXenes stabilization and applications. Broadly, this study demonstrates a potential new tool for ideal phase-property relationships of ceramics at the atomic scale.