Combustion

Since 1948, Purdue researchers have set the standard for combustion and propulsion experiments. Work at Zucrow Labs led to the development of the original Space Shuttle Main Engines. Today, new technologies allow propellants, combustors, and rocket engines to be conceived, constructed, and tested with unprecedented accuracy. With the blossoming private space industry, Purdue combustion engineers are in high demand.

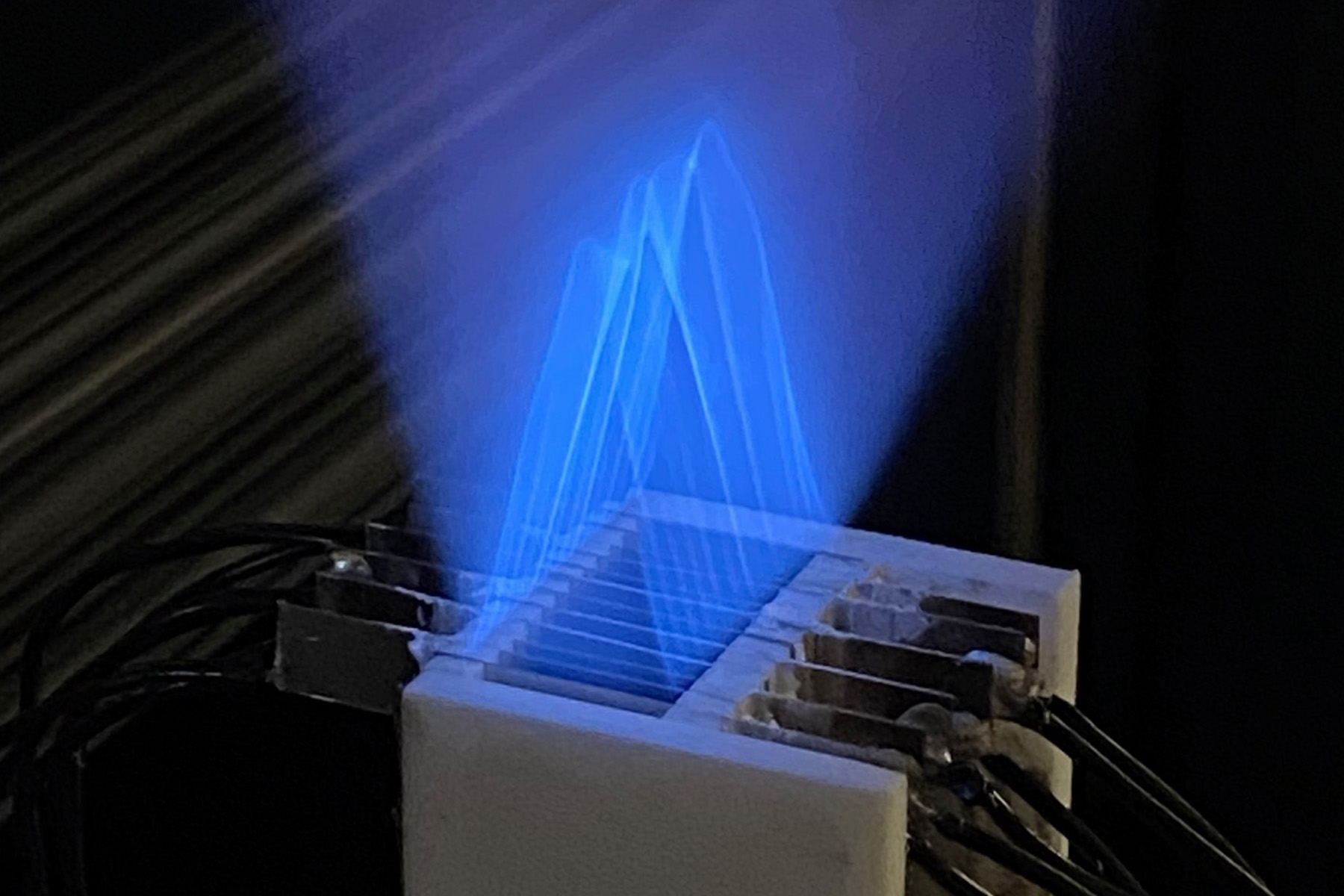

In addition, Purdue has unmatched research facilities in the diagnostics of flames and combustion. The High Pressure Combustion Laboratory at Zucrow Labs is the only facility of its kind in the world. It includes the Tebbe TDI Laser Lab, a 2,000 square-foot climate controlled facility, runs adjacent to 5 brand new test cells, for optimal inclusion of laser diagnostic measurements in combustion experiments.

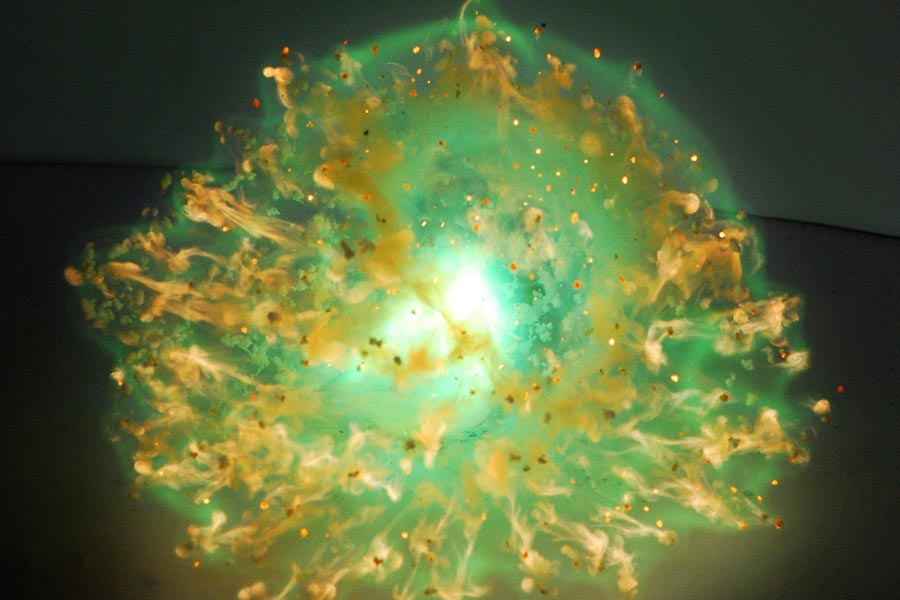

Purdue is also well known for its work with energetic materials: propellants, explosives, and pyrotechnics. At the Purdue Energetics Research Center, new advancements are being made in the formulation of rocket fuel, ammunition, controlled detonations and explosions, and much more.

Zucrow Labs is the largest academic propulsion lab in the world. Facilities include:

- Multiple reinforced concrete test cells with laser diagnostics

- Propellant labs with mixers, evaluation rigs, and safety equipment for remote operation

- Compressed air delivering 3300 cubic feet at 2200 psi

- Air heater, capable of testing at 1500°F at Mach 4

- On-site bulk storage and infrastructure for hydrogen, liquid oxygen, liquid nitrogen, and natural gas

- Data acquisition and storage with analog/digital sensors, high-speed cameras, and controls

More detailed info at purdue.edu/zucrow

Faculty in Combustion

- Laser-absorption spectroscopy, laser-induced fluorescence, & IR imaging sensors for gas temperature, pressure, velocity, and chemical species

- Molecular spectroscopy, photophysics, & energy transfer in gases

- Energetic materials (e.g., explosives & propellants) detection & combustion

- Combustion and propulsion systems (small and large scale)

- Biomedical sensing

- Predictive, multi-scale modeling and simulation of microstructure evolution in confined granular systems, with an emphasis in manufacturing processes and the relationship between product fabrication and performance.

- Application areas of interest include:

- (i) particulate products and processes (e.g., flow, mixing, segregation, consolidation, and compaction of powders),

- (ii) continuous manufacturing (e.g., Quality by Design, model predictive control, and reduced order models), and

- (iii) performance of pharmaceutical solid products (e.g., tensile strength, stiffness, swelling and disintegration), biomaterials (e.g., transport and feeding of corn stover) and energetic materials (e.g., deformation and heat generation under quasi-static, near-resonant and impact conditions, and formation and growth of hot spots) materials.

- Advancement of next-generation propulsion concepts including Rotating Detonation Engines (RDEs), Rotating Detonation Rocket Engines (RDREs) and Scramjet Engines

- Laser diagnostics development for applied thermal environments including RDEs, RDREs, gas-turbines, rockets, IC engines, and scramjet engines

- Laser Diagnostics and Spectroscopy for detonations, combustion, sprays, energetics, propellants, hypersonics, plasmas, and non-equilibrium flows

- Estimation of performance, efficiency and emissions using state of the art optical diagnostics (PLIF, CARS, TP-LIF, PIV, 3D Imaging, X-Rays, PIV, Molecular Tagging, Thermographic Phosphors and Pressure Sensitive Paints)

- Thermal-fluid behavior at the extremes, including turbulent, acoustically coupled, high-temperature, high-pressure, multiphase, and non-equilibrium reacting flows