Bert Gramelspacher: Electronic Miracle Worker

Every workplace has that one person everyone turns to when they need a problem solved. In the School of Mechanical Engineering, that person is Bert Gramelspacher. While his official title is Electronic Design Engineer, to the students, staff, and faculty of Purdue ME, his real title is “miracle worker.”

All in the family

As it turns out, serving Purdue Mechanical Engineers has always been in Bert’s blood.

“My grandfather graduated from Purdue, as did my father, and a lot of my cousins and close relatives,” he said. “I assumed his degree was in forestry, because that’s what my father studied, and they always owned or managed woodworking and lumber companies.”

But Bert got a surprise when he recently located his grandfather’s diploma, which reads: Claude August Gramelspacher, Bachelor of Science in Mechanical Engineering, 1916. “What a small world!” laughs Bert. “He was an ME student a hundred years ago, and now here I am following in his footsteps, helping ME students in the 21st century. What goes around comes around!”

Growing up in Jasper, Indiana, Bert clearly had a future in technical hands-on work. “I took everything in the house apart,” said Bert. “But my mother always got mad at me because I never put it back together!”

The family moved to Lafayette when he was 12, and Bert graduated from Southwestern High School (now a middle school in Tippecanoe County). After an associate’s degree at Vincennes University, he first got a job at the RCA television factory in Bloomington, but wasn’t happy being “in enemy territory.” So he moved back to Lafayette and enrolled at Purdue, where he finished an electrical engineering degree in 1979.

“I wanted to get something on my resume right after I graduated,” said Bert, “so I started working at one of the companies in Purdue Research Park called CTS Microelectronics. They made microelectric parts for cars, radios, electronic gear, satellites, and missiles for the military. I even worked on the circuitry for one of the first implantable pacemakers.”

In 2004, CTS closed their factory. Bert found himself out of a job for the first time in decades. So who could use a person with impeccable skills in electronics, who can fix just about anything?

“We knew Bert was the right choice for the job, because he looked uncomfortable in a suit!” laughs Mike Logan, Managing Director of Technical Services and then-supervisor of the Purdue ME Electronics Shop. “We needed someone with the technical knowledge, who could also get his hands dirty — and Bert was that guy.”

“We both worked at CTS Microelectronics for a time, so I knew how generous he was with his time,” said Steve Kessler, current E-Shop Manager. “He is the go-to person for help with vehicles, home appliances, gadgets, and pretty much anything else. I think his middle name should be MacGyver!”

Talking shop

There is very little downtime in the E-shop. During the summer, when most Purdue staff and faculty are vacationing, Bert and the E-Shop staff are busy building (and re-building) equipment for instructional labs. Bert has designed multiple custom setups to help faculty illustrate fluid mechanics, heat transfer, statics and dynamics, and more. They also support all the computers, networks, and accessories in the student computer labs.

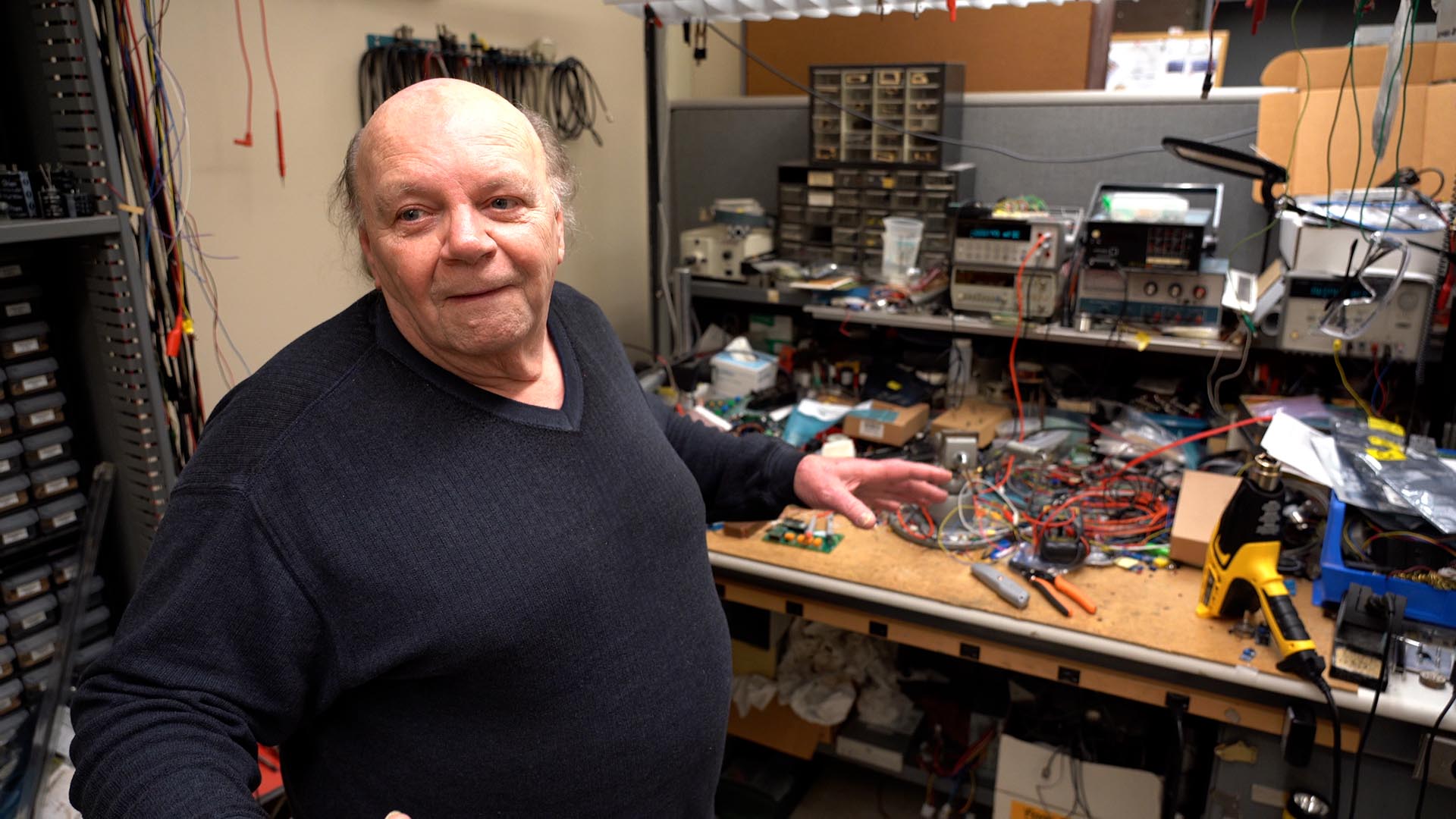

Bert’s section of the E-shop is a phantasmagoria of wires, cables, circuit boards, multimeters, oscilloscopes, and an untold variety of other testing equipment and tools. Give Bert a few minutes with a soldering iron, and he can fix any electronic or mechanical component — or design and build a new component that works better than the previous one.

And that’s all before the school year starts. Once students arrive, Bert receives a constant stream of visitors to the E-Shop, asking for help with all manner of experiments and assignments. And as the semester nears the end, panicked students flock to Bert for his help fixing their year-end prototype projects.

“Every semester, we have about fifty senior design teams designing new prototype projects, which they only have about 12 weeks to build,” said Bert. “They know how to assemble the mechanical systems, but they often need help with the electronics to interface with and control everything. So I sit down with them and help them understand how to make it all happen.”

Fly me to the moon

Bert is also called upon by faculty for higher-level research projects. When NASA awarded Issam Mudawar a grant to test cryogenic liquids in zero-gravity, he turned to Bert to help build it. “This apparatus used multiple heating systems to change liquid nitrogen from a liquid state to a gaseous state,” Bert explained. “They had a camera set up with backlighting so they could observe the phase change in real time, and it all had to happen in just 15 seconds because this apparatus was going on the vomit comet [the zero-gravity parabolic airplane]. I developed all the electronics, the control systems to manage the flow of liquid nitrogen and the heaters, and the sensors to record the results.”

The experiment was a success, making multiple zero-gravity flights in 2022. “This test rig is the first of its kind,” said Mudawar. “We were able to collect numerous highly-coveted cryogenic flow boiling datasets at various flow conditions in reduced gravity. These systems are crucial not just for space systems in low Earth orbit, but also for fueling future missions to both the Moon and Mars.”

Flipping switches

So after 19 years working in the E-Shop, what keeps Bert going? “I really enjoy all of it, but my favorite part is interfacing with the students,” said Bert. “It’s always rewarding when you see that little switch, that light bulb go on, and they get it. That’s so much fun.”

“I couldn’t ask for a better coworker than Bert,” said Tami Armstrong, Instructional Support Engineer. “While it’s common to find someone with either mechanical or electrical aptitude, it’s uncommon to have someone like Bert who is adept at both. He understands complex systems and has a wealth of knowledge plus experience. He is so dedicated to the students and faculty of ME, even on his days off he is sending me email about ME projects.”

“I mean, the man remodeled his house himself: plumbing, electrical, framing, finish work, everything,” said Mike Logan. “His broad expertise translates to more interesting and meaningful conversations with students. Bert is a trusted co-worker and friend. His knowledge, creativity, and broader interests have been an incredible asset to the University.”

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374