Computational Engineering

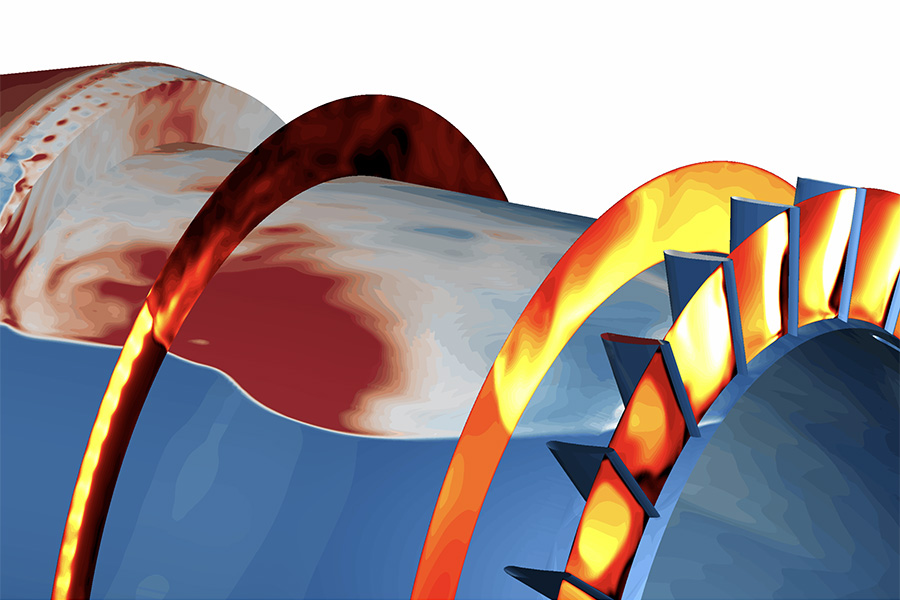

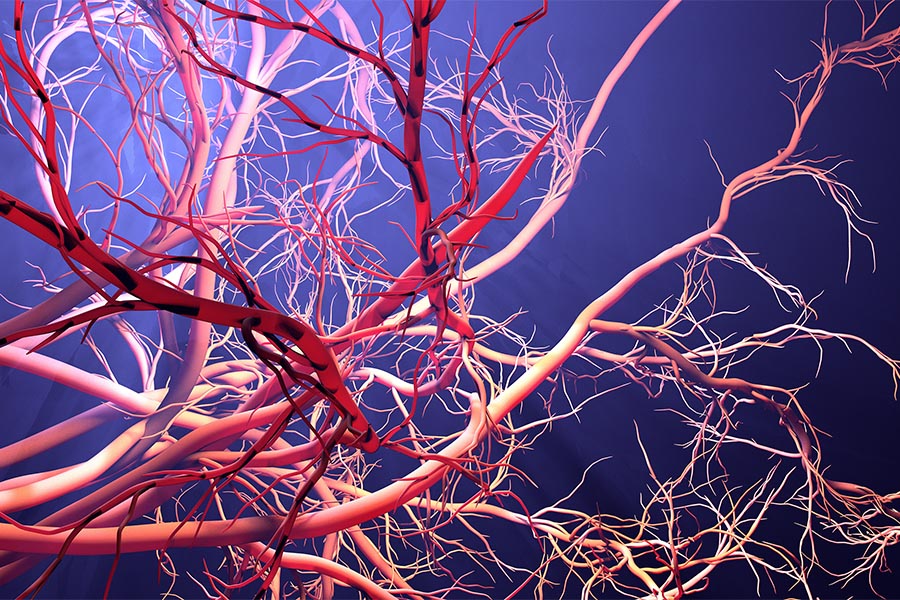

Along with theory and experimentation, computer simulation has become the third mode of scientific discovery. Tools like finite element analysis and uncertainty propagation allow our researchers to explore new frontiers in fluid dynamics, heat transfer, bioengineering, combustion, nanotechnology, materials modeling, design, and so much more. Using the data from thousands of simulations, they can construct models that will ultimately benefit people in real-world situations.

And there's no better place to explore that science than Purdue. We hosted the first computer science department in the country in 1962, and today, one of the top research supercomputer clusters in the country allows Purdue researchers to explore any possibility they can imagine.

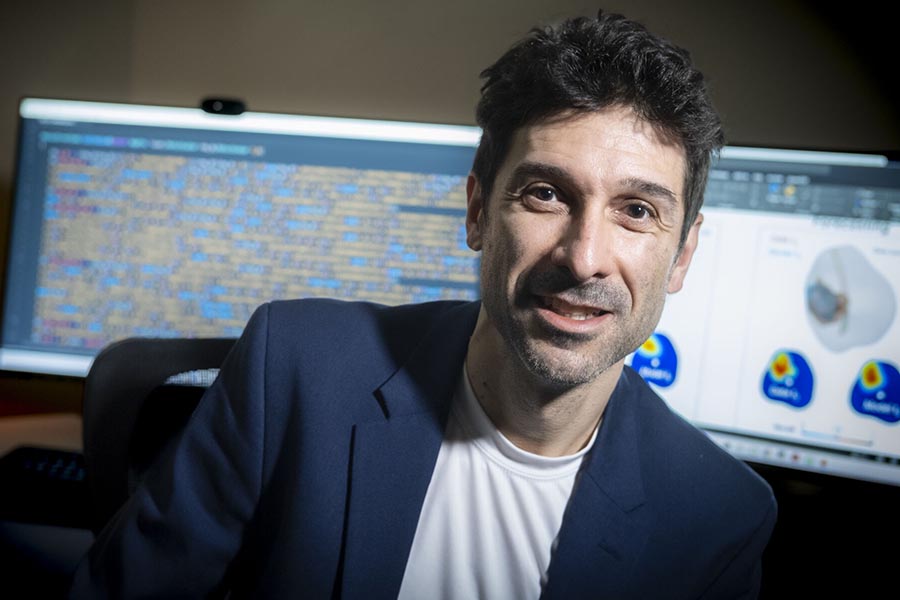

Faculty in Computational Engineering

- Modeling and simulation techniques for multiphase and multiphysics problems using the phase-field method.

- Isogeometric methods with applications in fluid and solid mechanics.

- Modeling and simulation tools for several biomechanics problems, including tumor growth, cellular migration and blood flow at small scales.

- Computational methods for fluid-structure interaction, especially when the problem involves complex fluids.

- Predictive, multi-scale modeling and simulation of microstructure evolution in confined granular systems, with an emphasis in manufacturing processes and the relationship between product fabrication and performance.

- Application areas of interest include:

- (i) particulate products and processes (e.g., flow, mixing, segregation, consolidation, and compaction of powders),

- (ii) continuous manufacturing (e.g., Quality by Design, model predictive control, and reduced order models), and

- (iii) performance of pharmaceutical solid products (e.g., tensile strength, stiffness, swelling and disintegration), biomaterials (e.g., transport and feeding of corn stover) and energetic materials (e.g., deformation and heat generation under quasi-static, near-resonant and impact conditions, and formation and growth of hot spots) materials.

- Contact mechanics

- Stresses, fatigue and friction of rolling/sliding

- Micro-mechanics of boundary and mixed lubrication regimes

- Spall initiation and propagation

- Surface science and damage

- Dynamics of ball and rolling element bearings and rotating systems

- Friction induced vibration and squeal in dry contacts

- Friction and wear of dry and lubricated contacts

- Virtual tribology

- Dry and lubricated fretting wear

- MEMS for in-situ monitoring of tribological contacts

- Discrete element modeling

- Design

- Acoustic and elastic metamaterial

- Fractional calculus and fractional mechanics

- Theoretical and computational mechanics

- Machine learning applied to computational mechanics

- Quantum algorithms for computational mechanics

- Structural health monitoring

- Wave propagation, structural dynamics and vibration control

- Adaptive structures

- Electrochemistry, mechanics, interfacial chemistry, and kinetics in energy storage systems

- Advanced synthesis, processing, and characterization techniques for energy storage materials

- Atomistic-scale modeling of chemical and mechanical properties in energy storage materials

- Multi-scale and multi-physics based modeling of Li-ion batteries and fuel cells

- Computational and experimental solid mechanics focused on fatigue, fracture, and multi-physics phase evolution problems

- Computational techniques including Finite Element Analysis (FEA), Isogeometric Analysis (IGA), geometric modeling, CAD and optimal design

- Heterogeneous Integration and Advanced Electronics Packaging with a focus on thermomechanical behavior, reliability, and electrical-thermal-mechanical co-design

- Discrete element method (DEM) modeling for particulate systems

- -- model development, e.g., fibrous particles, particle breakage, particle shapes

- -- application to manufacturing, e.g., storage and flow, blending, segregation, drying, coating, wet granulation

- Finite element method (FEM) modeling of powder compaction

- -- e.g., roll compaction, tableting, picking and sticking

- Multi-scale modeling (FEM combined with DEM) of powder dynamics

- -- model development and application to hopper flow, blending, and segregation

- Advanced electronics cooling and packaging technologies

- Phase-change transport phenomena

- Additive manufacturing of thermal management components

- Topological optimization and machine-learning-based design

- Thermal systems analysis for electrification and energy efficiency

- Microscale and nanoscale surface engineering for enhanced thermal transport

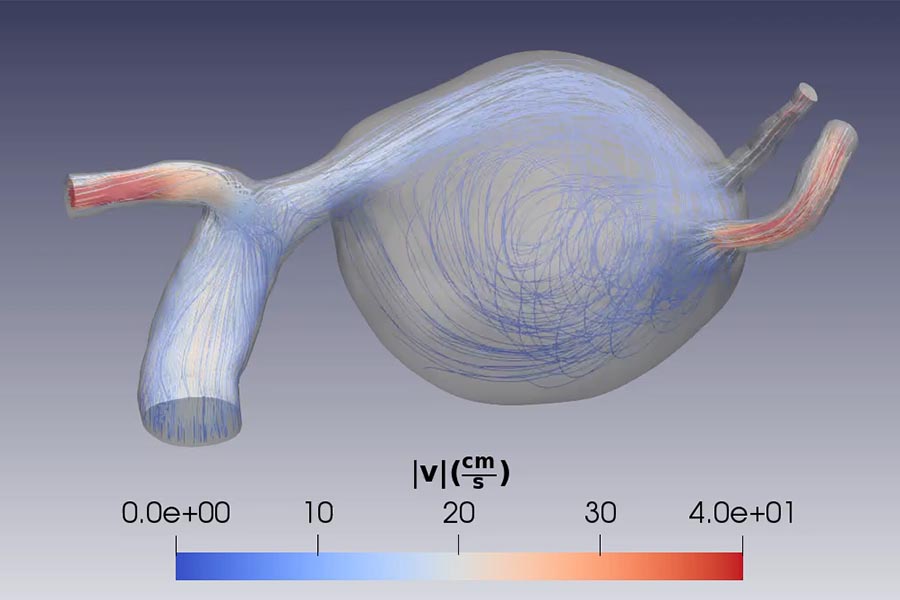

- Image-based computational and experimental fluid dynamics for porous-media and biomedical flows

- Translational research integrating high-performance CFD, image-based and physics-informed machine-learning, and uncertainty quantification to address unmet clinical needs

- GPU-parallelized lattice Boltzmann method for DNS and LES of turbulence

- Micro-bubble coalescence and detachment in microfluidics

- Deformation, stress, plasticity, fracture

- Multiscale modeling, first-principles, molecular dynamics simulations, and finite element modeling

- In-situ experiments

- Mechanics of redox active materials - Li-ion batteries, Na-ion batteries, all-solid-state batteries

- Mechanics of polymeric materials - organic electrochromics, superelastic organic semiconductors