Steel mill puts Purdue control theories into practice

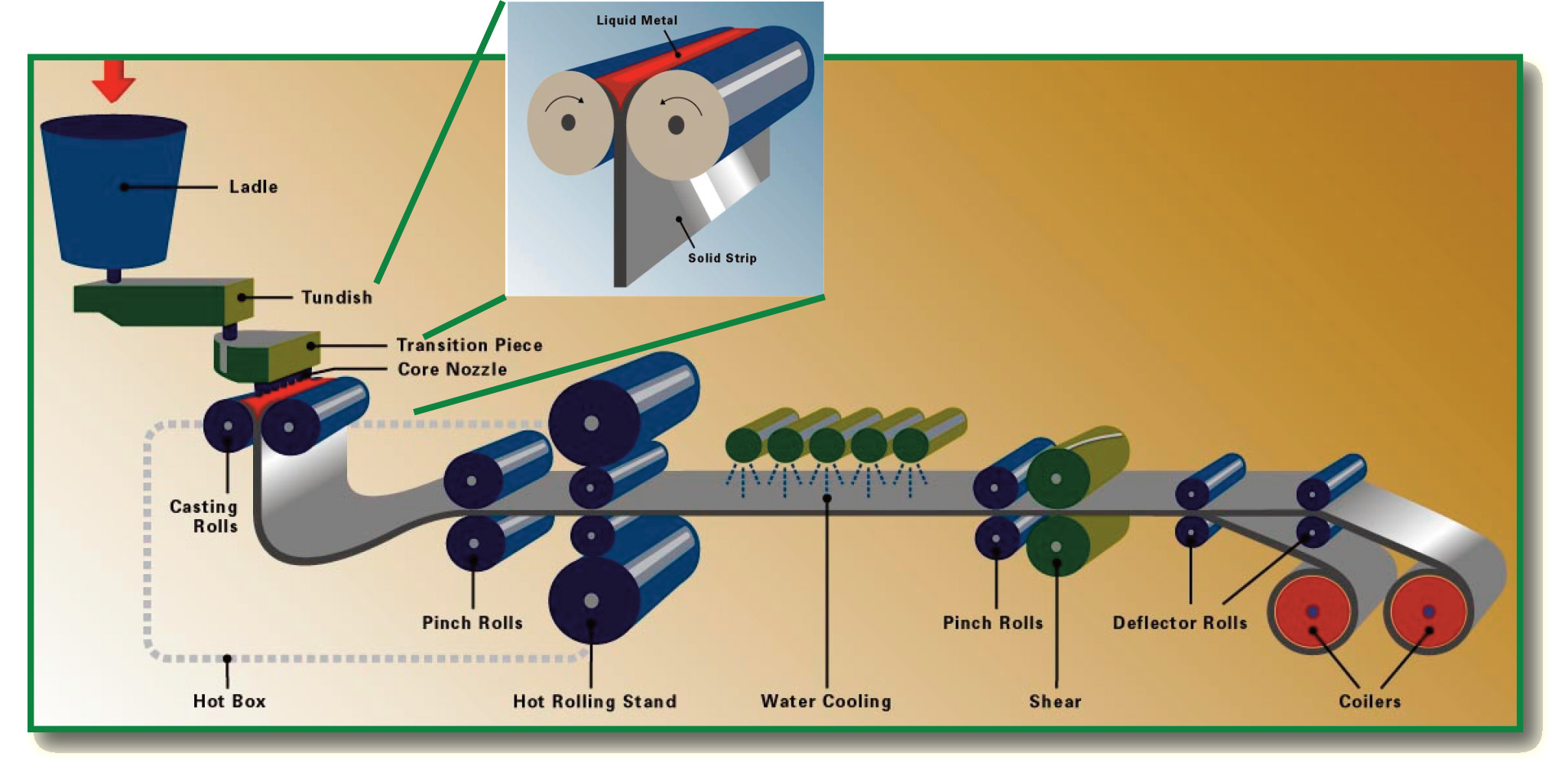

Rian Browne, a Ph.D. student in Mechanical Engineering, is leading the project. “In traditional casting, they pour molten steel into a mold, which has to solidify before it goes through rollers to create thin sheets,” said Browne. “Nucor has a process called Castrip®, where they use twin roll strip casting to pour molten steel between two rollers, and within milliseconds they can create a steel sheet just 1 to 2 millimeters thick.”

But that speed also brings challenges. “When you have molten steel that is thousands of degrees Celsius, you can’t easily put sensors nearby,” said Neera Jain, assistant professor of mechanical engineering, who jointly advises Rian with professor George Chiu. “So about 6 or 7 seconds go by between when the strip is formed, and when we actually get to check its thickness.” As a result, when imperfections occur, they can’t be identified until much later in the casting process.

Rian’s solution? Adjust the rollers in real time, to dynamically compensate for the imperfections. “We’re developing software using an algorithm called iterative learning control,” said Browne. “We know these rollers rotate once per second, so if we know the measurements further down the line, our software can send updated controls to the rollers’ positioning system. So we are constantly adjusting to get a more uniform and consistent cast.”

Nucor has already seen positive results from the Purdue collaboration. “With this process, we’ve been able to reduce variance in strip thickness by about 80%," said Browne. As a result of these tests, Nucor is now implementing the change in its Crawfordsville mill, and once proven, it will be implemented in other Castrip® facilities around the world. “It’s pretty cool that this international product will be using a control methodology developed right here at Purdue.”

Nucor has already seen positive results from the Purdue collaboration. “With this process, we’ve been able to reduce variance in strip thickness by about 80%," said Browne. As a result of these tests, Nucor is now implementing the change in its Crawfordsville mill, and once proven, it will be implemented in other Castrip® facilities around the world. “It’s pretty cool that this international product will be using a control methodology developed right here at Purdue.”

Neera Jain appreciates the spirit of collaboration between academia and industry. “This is a project that has benefitted us both,” she said. “Nucor have been very open with us, allowing us to test these control theories on their real-world equipment, which a lot of people don’t get to do. Rian was in Crawfordsville several times a week, and really became part of their team. They’ve been a model company to work with, and we’re so excited to see this process being put into practice.”

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Source: Neera Jain, neerajain@purdue.edu, 765-496-0436