Purdue team receives a DOE grant to develop next generation electrochemical looping heat pump systems

The three-year, $1.25-million grant from the US Department of Energy’s (DOE) Building Technologies Office is entitled “NO Vapor-compression, Electrochemical Looping Heat Pump (NOVEL HP)”. Initial development of the concept was funded through a grant from the CHPB, culminating in proof-of-concept experimental work and simulation assessments. The DOE grant will enable further development and a more comprehensive assessment that will move this technology closer to commercialization.

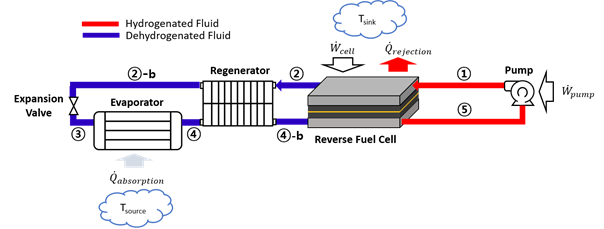

With the HVAC&R industry accounting for nearly half of the total energy consumed by US residential and commercial buildings, alternative systems need to be developed. The electrochemical looping heat pump technology can enable an improvement in energy efficiency of more than 20% compared to conventional vapor compression systems, depending on the operating conditions. They can also help transition to new refrigerants with low global warming potential.

The main goals of this project will be to develop two major improved components: 1) new electrochemically-active working fluids, and 2) high performance cells. These improvements will be enabled by a number of innovative system architecture concepts, which will ultimately result in a demonstration prototype of the electrochemical looping heat pump system.

The principal investigator is Davide Ziviani, Assistant Professor of Mechanical Engineering, and Associate Director of the CHPB. The team also includes James E. Braun, Herrick Professor of Engineering and Director of CHPB; Eckhard A. Groll, William E. and Florence E. Perry Head and Reilly Professor of Mechanical Engineering; and from the University of Illinois Urbana-Champaign, professors Jeffrey S. Moore and Joaquin Rodriguez-Lopez. Moreover, a partnership with Carrier, led by Larry Burns and Hafez Raeisi Fard, will be instrumental in developing and demonstrating an integrated prototype.

Source: Davide Ziviani, dziviani@purdue.edu

Scalability of Chemical Looping Heat Pump technology

Kim J., James N.A., Groll E.A., Braun J.E., Ziviani D.

http://doi.org/10.18462/iir.rankine.2020.1200

ABSTRACT: Air conditioning, space heating, and refrigeration account for approximately 40% of the electricity usage in the U.S. residential and commercial building sector. To improve energy utilization and reduce energy consumption, novel heat pumping technologies are needed. The concept of a chemical looping heat pump (CLHP) system has been previously investigated by the authors and shown to have the potential for significant performance improvement compared with conventional vapor compression systems. The current work investigates the scalability of a CLHP system by means of a detailed thermodynamic model coupled with a 2D-discretized electrochemical cell model. Parametric studies on the cell size as well as flow rate of the working fluids (e.g. Isopropyl alcohol and Acetone) are performed to identify requirements for meeting target cooling capacities for residential and commercial building applications. Based on the simulation results, trade-offs between system performance and cell sizes are identified. For a 7 kW residential heat pump with a target COPc of 4.0, a minimum of 3000 stacks having a surface of 8,000 cm2 per stack (1,000 cm2 active area per cell) is required.