Malott Innovation Awards showcase prototypes

The Malott Innovation Awards are the culmination of ME463, Purdue's capstone class for seniors in Mechanical Engineering. Teams of students work closely with faculty members and industry partners to create prototype products, continually refining and improving them using the knowledge from their engineering courses over the last four years. At the end of the semester, the students present their final prototypes to a panel of Purdue ME alumni who work in various industries; this panel selects the award winning teams.

Because of the restrictions of the COVID-19 pandemic, only some of teams were able to work on their projects in person (socially distanced). Others completed their projects entirely remotely; some of them in multiple time zones, and even in multiple countries!

1st Place: B-FIT: Brace For Impact Technologies (Patrick Lee, Tim Glavan, Edward Marcheselli, Daniel Payne, Matt Piazza, Rishi Verma). Over 900,000 knee surgeries are performed in the US annually. With the pandemic, it has become increasingly difficult for people to see an in person physical therapist to properly recover from these surgeries. The B5 Recovery Brace will allow customers to work with their physical therapist remotely, administering the appropriate protocol for their unique recovery plan. Common aspects of the recovery process for knee surgeries includes heating, cooling, compression, and angle locking. No single product on the market offers all four of these functionalities. This requires the patient to switch between multiple recovery devices for each recovery aspect, a cumbersome process that requires the help of a caregiver. The B5 Recovery Brace integrates all four required functionalities in a compact system and automates these processes such that patients can operate the device independently. The system can be manufactured for $520, which can be profitable with a competitive market price.

2nd Place: RadiCool (Ameya Ghai, Cole Breseman, Nick Wegh, Conrad Adams, Mario Trivella, Mason Pottschmidt, Dianna LaRocco). This project consists of a radiative pre-cooler for an AC system. It employs radiative heat transfer to reject energy into deep space by driving water through a pipe array coated in a BaSO4-acrylic paint. The paint has high reflectivity in the solar spectrum and high emissivity in the sky-window, enabling it to cool surfaces several degrees below ambient temperature, while using no power other than the minimal amount required for a small water pump. The pipe array is embedded in a mid-IR reflective trough, allowing the bottom portion of the pipes to also radiate energy to deep space and improving the cooling performance by a factor greater than two. Water cycling through the radiative cooling system cools down the airflow driven by existing AC units using a heat exchanger, resulting in a significant reduction in the cooling load and an increase in AC efficiency up to 80%, lowering energy costs and carbon emissions.

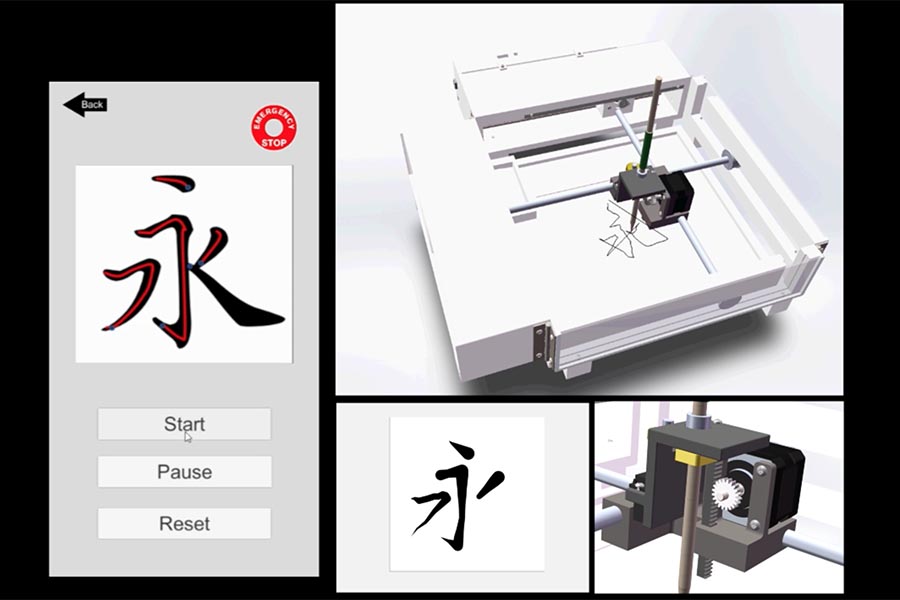

3rd Place: E-Artists (Kate Winger, Yijie Chen, Nathan Holt, Jiaming Jin, Hao Li). Calligraphy is a highly refined art form. Due to the complexity of controlling writing speed, pressure, and direction of the brush, it is difficult for people to learn, and it is increasingly expensive to hire a calligraphy master. The E-Artists have designed the Robotic Calligraphy Tutor, a robot capable of producing calligraphy characters and teaching users to make these characters themselves. For under $200, users will choose between robot-driven training mode and feedback-oriented practicing mode, and can choose from hundreds of characters in the library. Four motors give the robot four degrees of freedom, and the ergonomic design is equally comfortable for left and right-handed people. This compact design fits on any table, and Magic Paper allows users to produce characters with water and reuse the paper once the water has dried. The accompanying Android and iOS application puts users in full control of their tutoring experience.

Outstanding Prototype Award: Boiler Bakers (Steve Mazzochi, David Kuenzel, Spencer Losing, Adam Post, Joshua Menezes, Carolina Alongi Curto). People are cooking at home now more than ever and the need for healthy, quick food is at an all-time high. Measuring multiple spices for one dish leads to spills, inconsistent measurements, and frustration, taking the joy out of cooking. Existing products offer little relief, implementing few time-saving measures or selling at unrealistic prices. MeasureMINT fills this market gap by providing an affordable, automatic spice dispenser. Its screen-based interface allows users to choose either a recipe and serving size or an individual spice and quantity. A motor then rotates the desired spice to the outlet of the machine where a second motor then dispenses the ingredient for the user. Accurate dispensing is ensured every time so that meals are delicious, and customers are satisfied.

About the Malott Innovation Awards

About the Malott Innovation Awards

The Malott Innovation Awards are supported by an endowment created in 2007 by Thomas J. Malott (BSME '62, HDR '02), to foster an innovation culture among Purdue Mechanical Engineering students. Malott is the former president, CEO and director of Siemens Energy and Automation. His career included executive positions with Parker-Hannifin and the Ransburg Corp., as well as serving on several corporate boards. He was an inaugural member of the Purdue Foundation Development Council and was awarded the Outstanding Mechanical Engineer and Distinguished Engineering Alumnus awards in 1991 from the university.

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Source: Greg Jensen, jensen23@purdue.edu