NextHouse: creating the next generation of factory-built housing

“Many of the construction techniques used to build housing in the U.S. haven’t changed since the Industrial Revolution,” said James E. Braun, Herrick Professor of Engineering and director of the Center for High Performance Buildings at Purdue University. “We don’t just need more homes — we need better homes that prioritize affordability, sustainability, and resilience. The only way to do that is to change our paradigm of how homes are built.”

The NextHouse team’s initiative is a moonshot, aiming to harness the expertise of industry and academia to create a revitalized, fully-automated, and scaled-up factory-built housing industry.

“Manufactured homes have been around since the early 20th century,” Braun said. “But their processes haven’t kept up with 21st century technology, labor, or supply chains. Plus, their housing products don’t have mass customer appeal — only about 5% of housing in the U.S. today is built in a factory. We’re going to change that for the better.”

Their strategy is to “productize” housing, enabling economies of scale through standardizing the manufacturing and assembly of modular elements. “We want assembling a home to be as simple and customizable as assembling LEGO bricks,” Braun said. “NextHouse will enable a new wave of sustainable, affordable, and equitable housing, as well as a new pipeline of labor and manufacturing processes to transform that sector of the economy.”

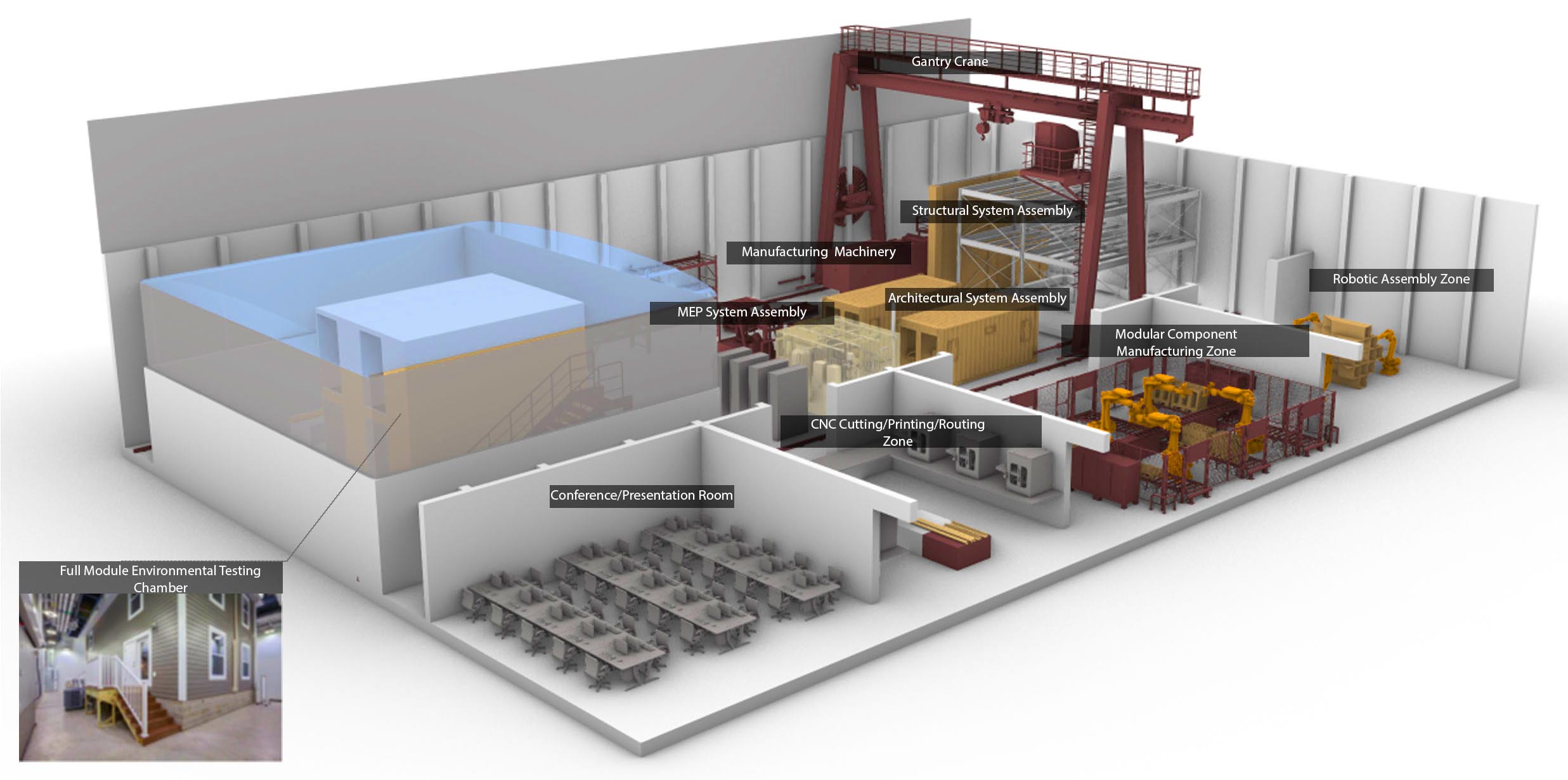

One of the most significant aspects of NextHouse will be the construction of a large prototyping and testing facility on Purdue’s campus. This facility will enable experimentation of construction techniques for modular housing, as well as a training center for workers. It will also contain a massive house-sized environmental chamber called the Housing Environmental Evaluation Testing (HEET) Lab, enabling controlled testing and evaluation of full-scale finished housing products under varying environmental conditions.

“The new facility is just one aspect of NextHouse that will be a draw for industry partners,” Braun said. “We are gathering an industry consortium of housing companies, material suppliers, architectural firms, and supply chain providers. We’re also building relationships with government agencies on every level, so that there will be a smooth pathway from conducting research to putting it into practice in the real world.”

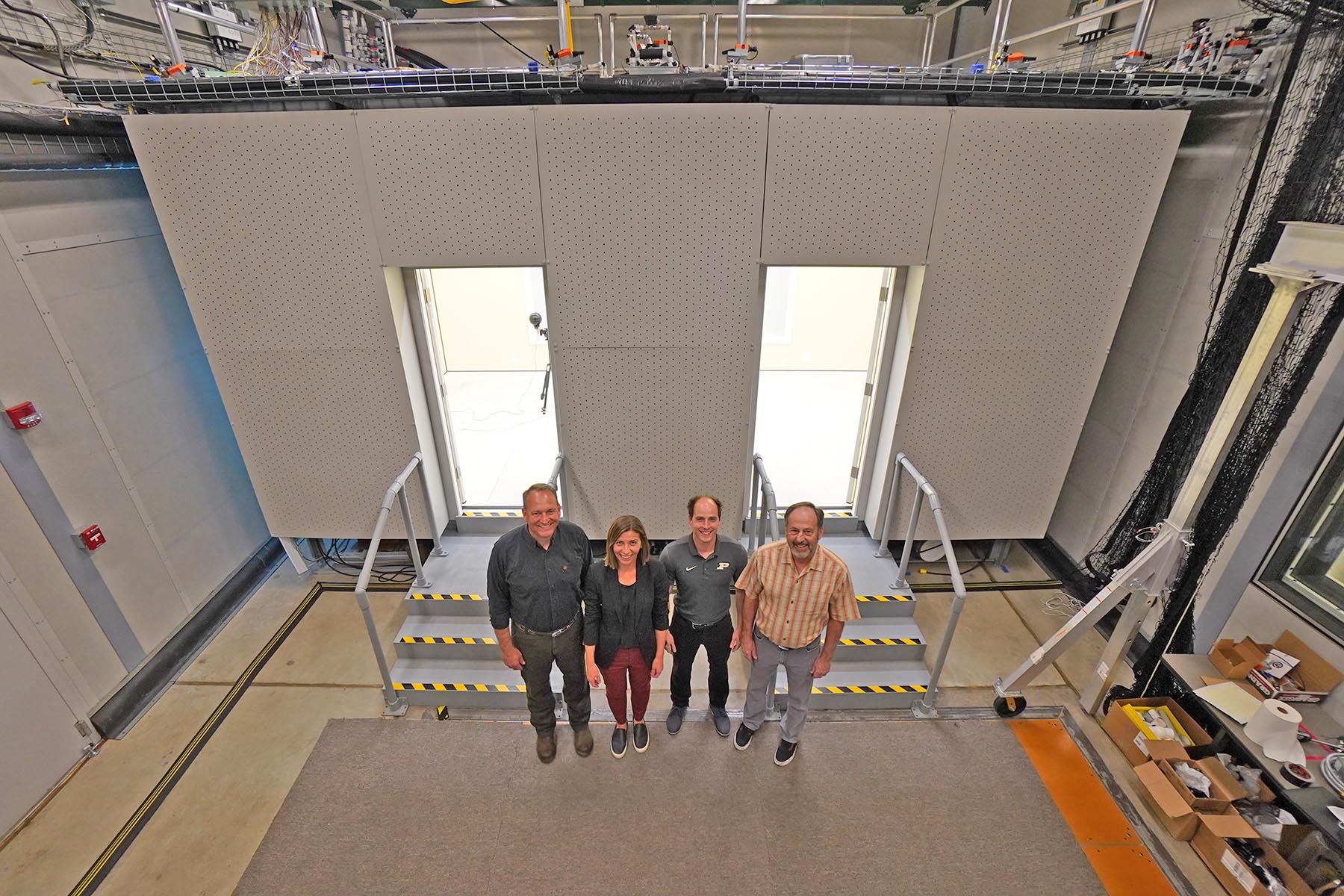

The NextHouse team has already been testing aspects of the program in small scale. In 2022, they developed a building-within-a-building test facility to determine how fully-reconfigurable climate control equipment can be pre-built into the walls themselves. Now they hope to scale up these experiments to a full-size house.

The team has received $1 million from the National Science Foundation (NSF) to develop the NextHouse ecosystem, and is currently competing for a $160 million award from the NSF Regional Innovation Engines program that would establish Indiana and southern Michigan as the “Silicon Valley” for sustainable, cost-effective housing. The regional ecosystem includes partnerships with the University of Michigan, Notre Dame, Michigan State, Ivy Tech, and Lansing Community College. The program is being run by the Purdue Applied Research Institute (PARI) with a NextHouse leadership team that includes Braun; Travis Horton, professor of civil engineering; and Panagiota Karava, professor of civil engineering.

“The NextHouse initiative has tremendous potential,” said Mark Lewis, president and CEO of PARI. “Their goals align perfectly with our mission of enhancing Purdue’s ability to translate discoveries into innovative solutions and services for mission-oriented government and industry.”

“Purdue is the perfect place to build something like this,” said Braun, who was recently recognized as the #1 scholar in the world for heating, ventilation, and air conditioning. “Herrick Labs has been collaborating with the building industry on research since 1958. We host one of the largest conferences in the world devoted to HVAC and smart buildings. We’ve worked hard to develop these close relationships with industry, academia, and government. Now with NextHouse, we’re going to leverage that expertise to transform the factory-built housing industry, and hopefully transform people’s lives as well!”

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Source: Jim Braun, jbraun@purdue.edu