Winning senior design project helps people with neuropathy learn to walk again

The Malott Innovation Awards are the culmination of ME463, Purdue's capstone class for seniors in Mechanical Engineering. Teams of students work closely with faculty members and industry partners to create prototype products, continually refining and improving them using the knowledge from their engineering courses over the last four years. At the end of the semester, the students present their final prototypes to a panel of Purdue ME alumni who work in various industries; this panel selects the award winning teams.

The top teams from the Spring 2023 Malott Innovation Awards are:

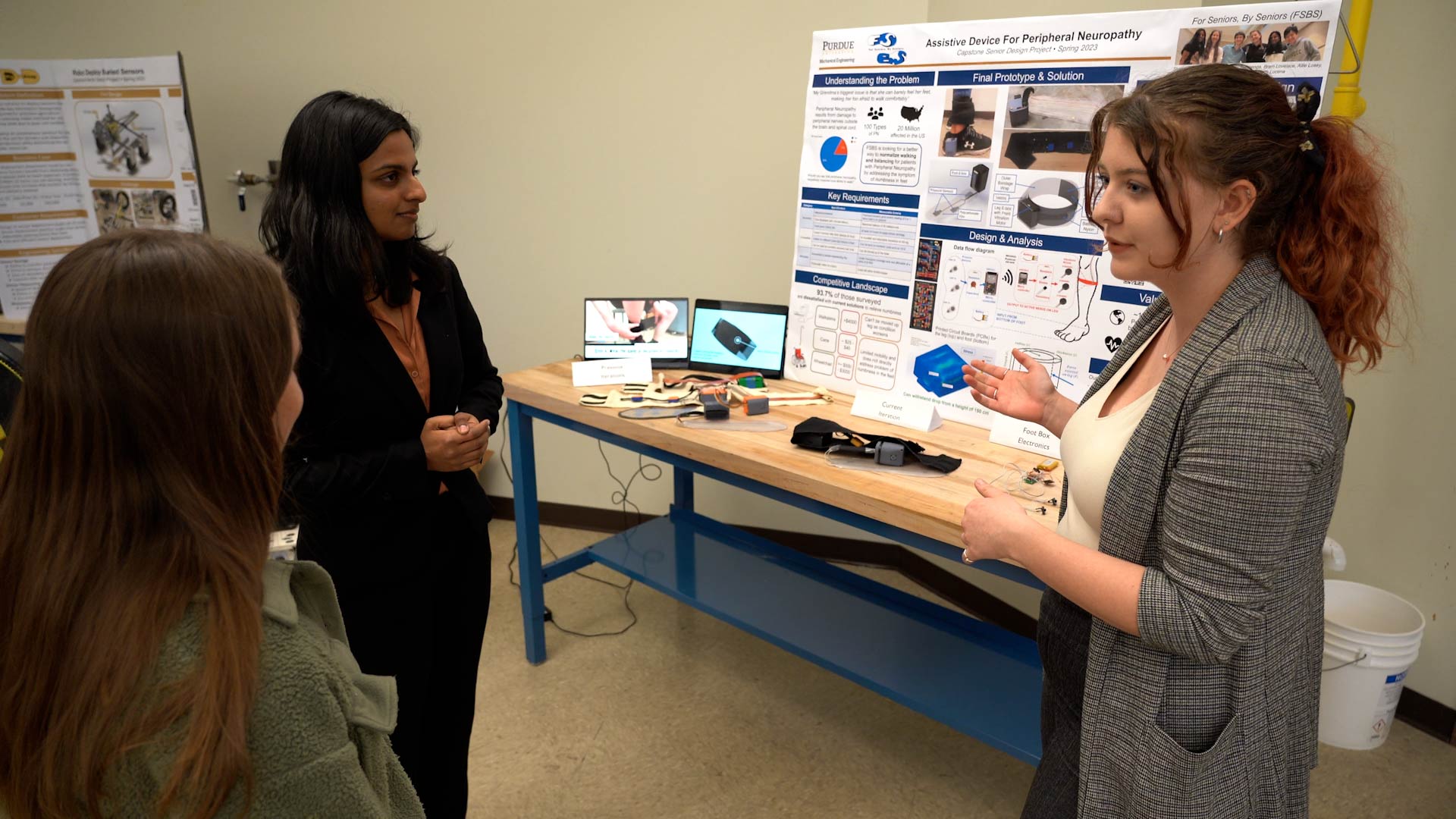

1st place: For Seniors By Seniors, Allison Losey, Bram Lovelace, Katherine Michelle Lucena, Skyler Nannenga, Shivani Pranatharthi Haran, Smrithi Pranatharthi Haran. Peripheral Neuropathy affects millions worldwide, causing pain or numbness in the limbs, especially the feet. This may cause limited mobility, forcing patients to rely on canes or wheelchairs. FSBS has developed a compatible bio-sensory insole that wirelessly connects to a vibrational feedback band to restore independence on foot affordably. The insole sends pressure sensor data from three primary areas responsible for balance in the foot to a microcontroller transmitter, which clips onto the user's shoe. The transmitter then sends a signal to the band, which is worn around the leg, where three vibration boxes are aligned with the sensors in the insole. This triggers vibrotactile feedback when the user's feet touch the ground. With a flexible height option, the device can cater to the spread of numbness up the leg over time, making it a modern solution for an aging population. Our product is also accessible and over 80% cheaper than leading wired market solutions.

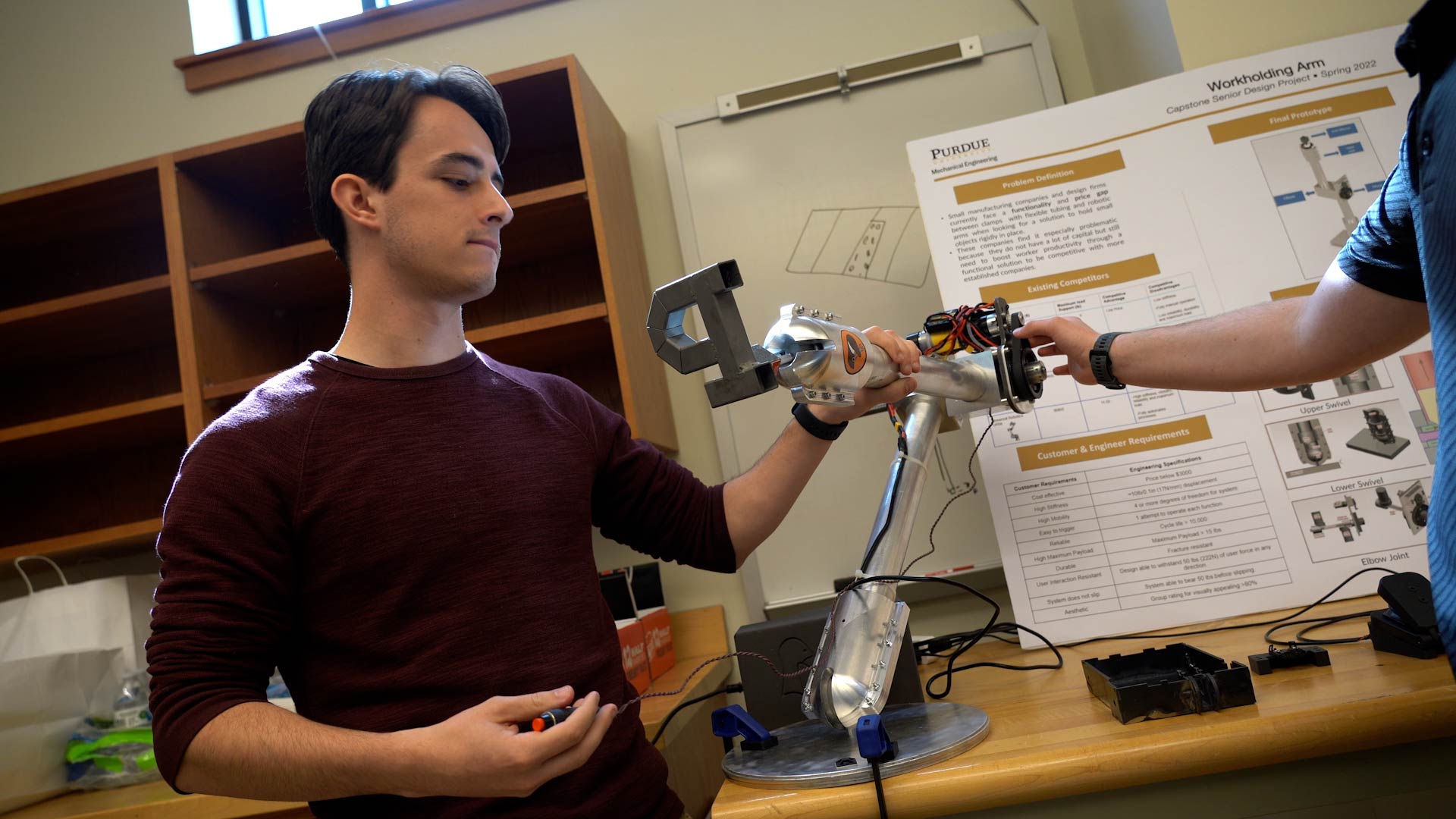

2nd place: Intuitive Workholding Inc., Aidan Powers, Julian Petrillo, Susan Evans, Alejandro Santamarina, Luis Almeida. Intuitive Workholding Inc. sought to solve a problem experienced by small scale manufacturers and creative makers everywhere. When working on a small to medium sized object for manufacturing, the ability to use precise placement and rigid positioning is ideal. With existing low-end solutions such as table and gooseneck clamps, the user must choose to rigidly hold an object or to place it in the correct orientation. High end solutions, such as robotic arms, are expensive and contain features that users may not need, such as complex automation. Intuitive Workholding's Arm fills the gap with the rigidity of the robotic arm, and the versatile posing of low-end solutions at an affordable price. Key features Intuitive Workholding incorporated were 6 degrees of freedom, easily swappable end effectors and bases, a button or foot pedal to toggle between posable and rigid, and an affordable price. The Workholding Arm is an ideal solution for holding a small to medium object rigidly in place for any orientation the user may need.

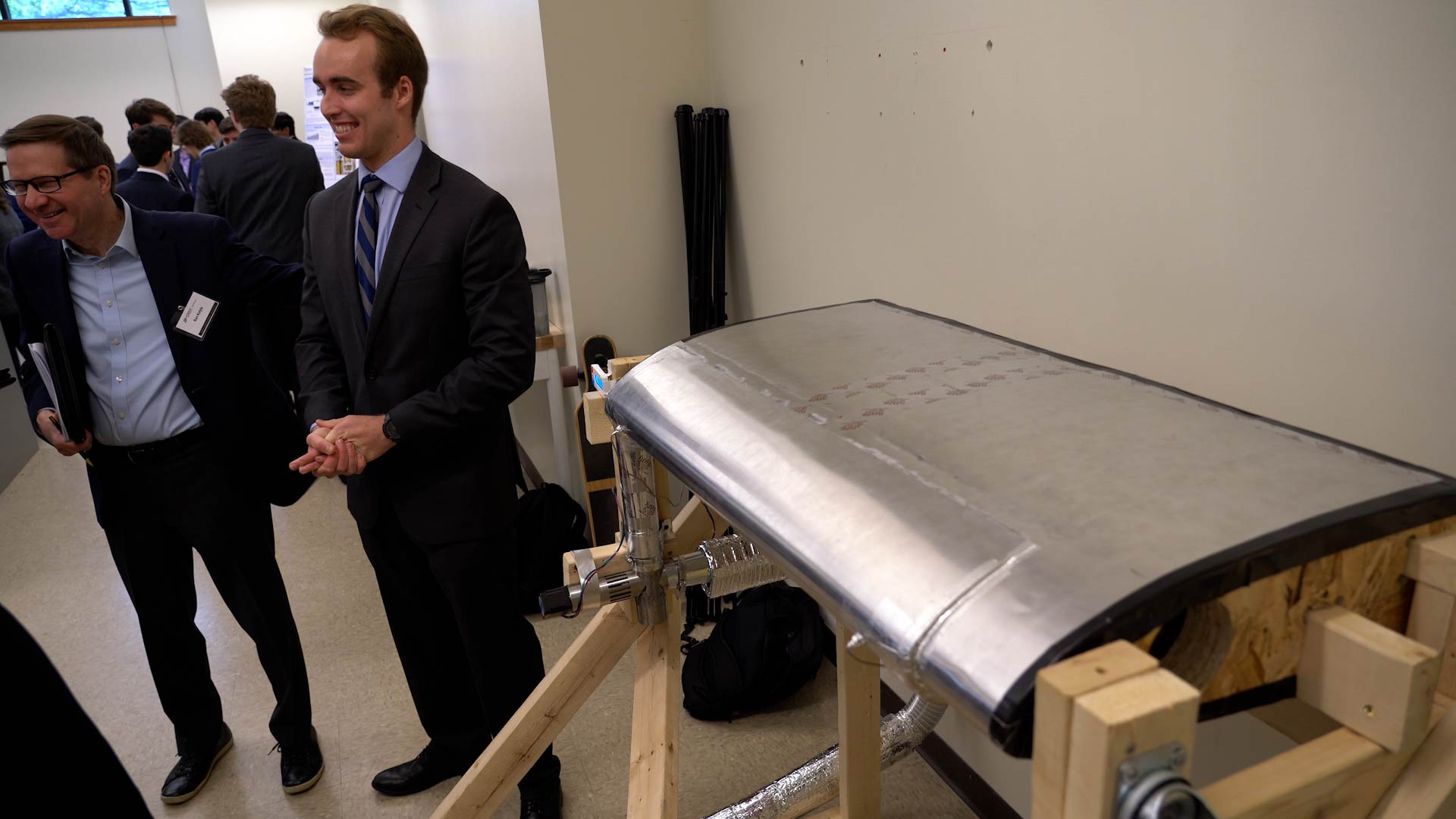

3rd place: Purdue Wild Wings, Matthew King, Noah Boursier, Kylie Morton, Seamus Hettinger, Kai Wilson. Airframe icing is a critical issue facing general aviation aircraft resulting in numerous fatalities every year. While deicing solutions exist for large commercial aircraft, the market is extraordinarily limited for smaller light general aviation aircraft. The few solutions tailored to this group of planes have major downsides. They are prohibitively expensive and negatively impact aircraft performance. Purdue Wild Wings has proposed a novel solution which recycles heat from the existing exhaust of the engine and reroutes it to heat the leading edge of the wings. By reclaiming existing energy, we have managed to minimize parasitic loads on the aircraft and produce an extraordinarily light system. The team has overcome many challenges throughout this project. The unique high temperature and low weight design constraints mandated that simple components such as a valve had to be designed and manufactured in house as existing products did not meet our requirements. While this added time and complexity to the project, the end result fulfills our mission.

About the Malott Innovation Awards

About the Malott Innovation Awards

The Malott Innovation Awards are supported by an endowment created in 2007 by Thomas J. Malott (BSME '62, HDR '02), to foster an innovation culture among Purdue Mechanical Engineering students. Malott is the former president, CEO and director of Siemens Energy and Automation. His career included executive positions with Parker-Hannifin and the Ransburg Corp., as well as serving on several corporate boards. He was an inaugural member of the Purdue Foundation Development Council and was awarded the Outstanding Mechanical Engineer and Distinguished Engineering Alumnus awards in 1991 from the university.

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Source: Greg Jensen, jensen23@purdue.edu, 765-496-0214