Reverse osmosis breakthrough will come to life at Purdue

With climate change threatening fresh water supplies around the world, scientists are focused on desalinating seawater as a possible large-scale alternative. But there’s a catch. “Desalination plants require a lot of energy,” said David Warsinger, Assistant Professor of Mechanical Engineering. “Even small improvements to the process – a few percentage points of difference – can save hundreds of millions of dollars and help to keep CO2 out of the atmosphere.”

Warsinger’s lab has been experimenting with reverse osmosis – the primary process for water desalination – since his doctoral work in 2015, when he helped to develop the idea of “batch reverse osmosis.” Rather than keeping a constant flow of seawater at high pressure levels, a batch process takes in a set quantity of water at one time; processes it; discharges it; and then repeats the process with the next batch.

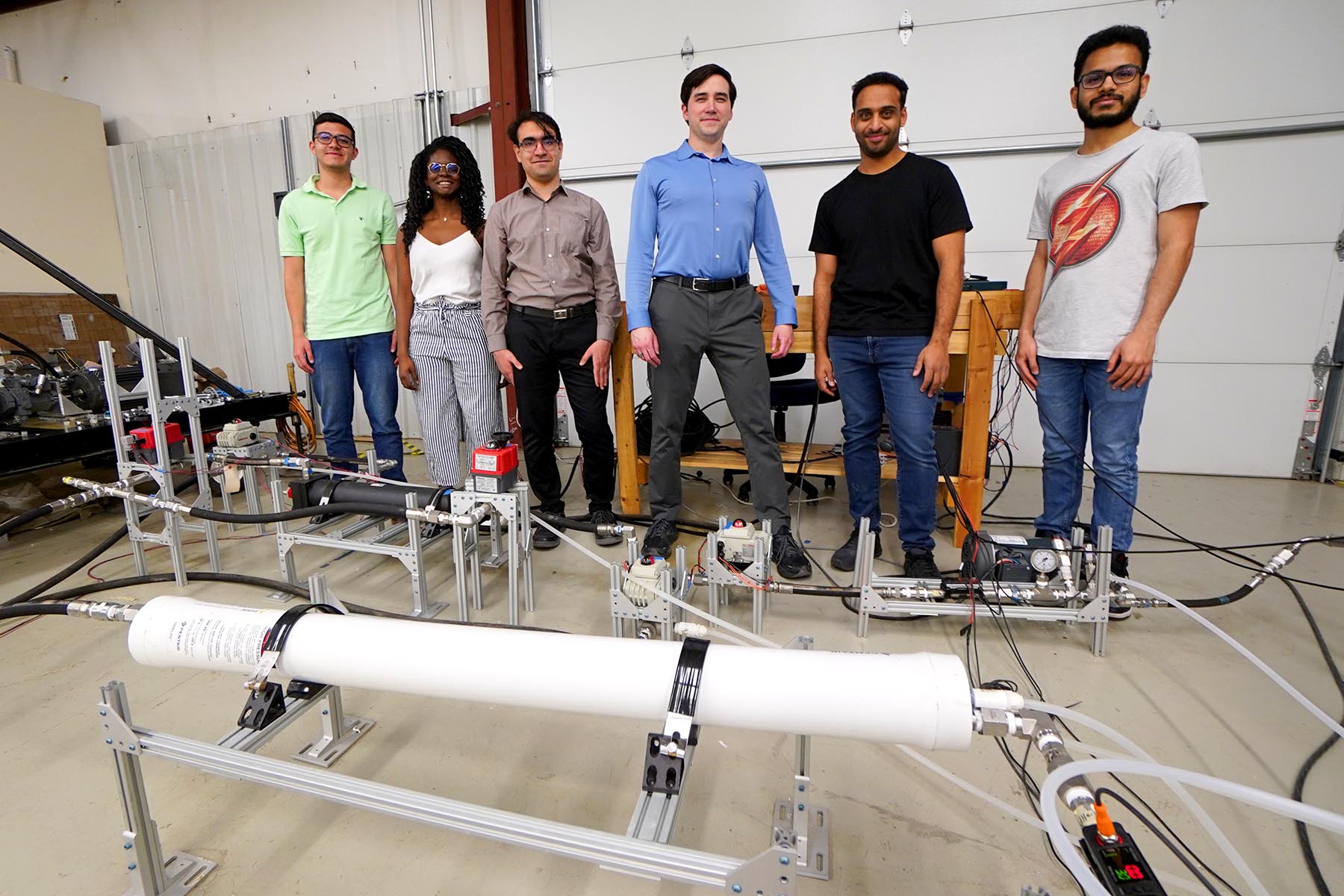

Warsinger has invented several configurations for batch reverse osmosis which achieve higher efficiency by increasing pressure over time to closely follow osmotic pressure. This is achieved with a volume-changing high-pressure tank, which is expected to further reduce mixing losses and downtime between cycles. Warsinger’s team built a lab-scale model in 2021, and theoretically proved that this technique has the potential to be the lowest energy consumption ever for a seawater desalination process.

The U.S. Department of Energy is funding a larger pilot project through its desalination hub, the National Alliance for Water Innovation (NAWI). Total cost for the project: $1.67 million over three years, starting in May 2023.

Warsinger’s team will begin building the system at Purdue, including high pressure pumps, valves, and the vital reciprocating piston tank – but at a much larger scale. “Our lab-scale project processed about one gallon of water per minute,” said Warsinger. “The new pilot project will be at least ten times bigger than that.”

Once the machinery is in place, the system will be transported to the Colorado School of Mines, where it will undergo real-world tests using discharge water from iodine mines. “This is actually a much bigger challenge than using seawater,” said Warsinger. “There’s a paradigm that reverse osmosis systems only work at certain salinities; but we think we can do better than that. By using this iodine-rich water, we plan to show that our system is both more energy-efficient, and able to deal with fouler water than previously thought possible.”

David’s co-principal investigators are José Garcia-Bravo, Associate Professor at Purdue Polytechnic Institute; Tzahi Cath, Ben L. Fryrear Professor of Civil and Environmental Engineering at Colorado School of Mines; and Kris Villez, Senior R&D Associate at Oak Ridge National Laboratory. The team also includes John Lienhard, Abdul Latif Jameel World Water and Food Security Professor at MIT; Emily Tow, Assistant Professor of Mechanical Engineering at Olin College of Engineering; Robert Huehmer, Senior Process Technology Engineer at DuPont; Quantum Wei, Co-Founder of Harmony Desalting; Doug White, Executive Vice President for Water Solutions at NGL Energy Partners; and Terry Brix, President of Brix-Berg Company. Patent applications have been filed via the Purdue Research Foundation Office of Technology Commercialization for these water treatment techniques. Funds for the initial prototyping came from the Desalination and Water Purification Research Program, US Bureau of Reclamation, award number R21AC10168-00.

“Water is an extremely valuable resource,” said Warsinger. “We want to be able to bring fresh water to places where it’s most needed, while also reducing our energy consumption in the process.”

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Source: David Warsinger, dwarsing@purdue.edu

Double-acting batch reverse osmosis configuration for best-in-class efficiency and low downtime

Sandra Cordoba, Abhimanyu Das, Jorge Leon, Jose M Garcia, David M Warsinger

https://doi.org/10.1016/j.desal.2021.114959

ABSTRACT: Energy consumption in reverse osmosis has decreased substantially over the last few decades thanks to the implementation of energy recovery devices, high efficiency pumps, and improved membranes. However, to further increase the adoption of the technology, its energy needs must still be reduced. Batch and semi-batch reverse osmosis configurations have shown potential to be the most energy efficient reverse osmosis variants, but have remaining inefficiencies from brine mixing and high downtime. In this study, we modeled in new detail a further improved double-acting batch reverse osmosis system that uses a high-pressure tank with a reciprocating piston. A high-pressure pump is used to fill the inactive side of the high pressure tank with feed that pressurizes the reverse osmosis system during the permeate production stage; the feed is then used as the working fluid for the next cycle of the system. Additionally, to account for the dynamic behavior of the system under different operational conditions, a hydraulic simulation model was developed to accurately predict the evolution of the pressure and other important parameters over time. A specific energy consumption of 1.88 kWh/m3 was calculated for seawater with a salinity of 35 g/kg, recovery of 50%, and a permeate flux of 15 LHM, and lower values SEC were obtained for lower permeate fluxes. Moreover, the downtime was found to be below 10% of the cycle time, without significantly increase the energy consumption of the system. This design also showed the potential to reduce the start-up time compared to previously proposed batch RO configurations.