Winning senior design project makes graphene manufacturing easier

The Malott Innovation Awards are the culmination of ME463, Purdue's capstone class for seniors in Mechanical Engineering. Teams of students work closely with faculty members and industry partners to create prototype products, continually refining and improving them using the knowledge from their engineering courses over the last four years. At the end of the semester, the students present their final prototypes to a panel of Purdue ME alumni who work in various industries; this panel selects the award winning teams. Many teams also collaborated with industry, working on sponsored projects from companies like Cummins, American-Darling fire hydrants, Detroit Diesel, and Ford Motor Company.

The top teams from the Spring 2022 Malott Innovation Awards are:

1st Place: Atomic Stamp, Alex Bauer, Dylan Balter, Jacob Weber, Mark Ragei, Reese Holloway, Sujal Yagnik. Atomic Stamp pursues groundbreaking research in 2D solids to accelerate scalable commercialization of this nascent material class. It proves to be a profitable product with global interest that allows researchers to innovate on nanoscale heat transfer solutions in everyday devices like smartphones and computers. Atomic Stamp overcomes the shortcomings of dirty, laborious chemical etches and other commercial devices’ inability to measure parameters. Our device allows optimization of a repeatable, controllable, and clean transfer of graphene onto substrates of arbitrary composition and topography. Our automated, electromechanical device measures and controls pressure, speed, temperature, and angles dictating adhesion during contact. Practically, the device achieves unique rotational peeling motion by implementing a custom tilt stage and a stamp assembly composed of load-cell, thermocouple, heater, and thermal release tape. The device enhances percent coverage and quality of graphene while decreasing total transfer time from days to minutes through our material preparation and transfer techniques.

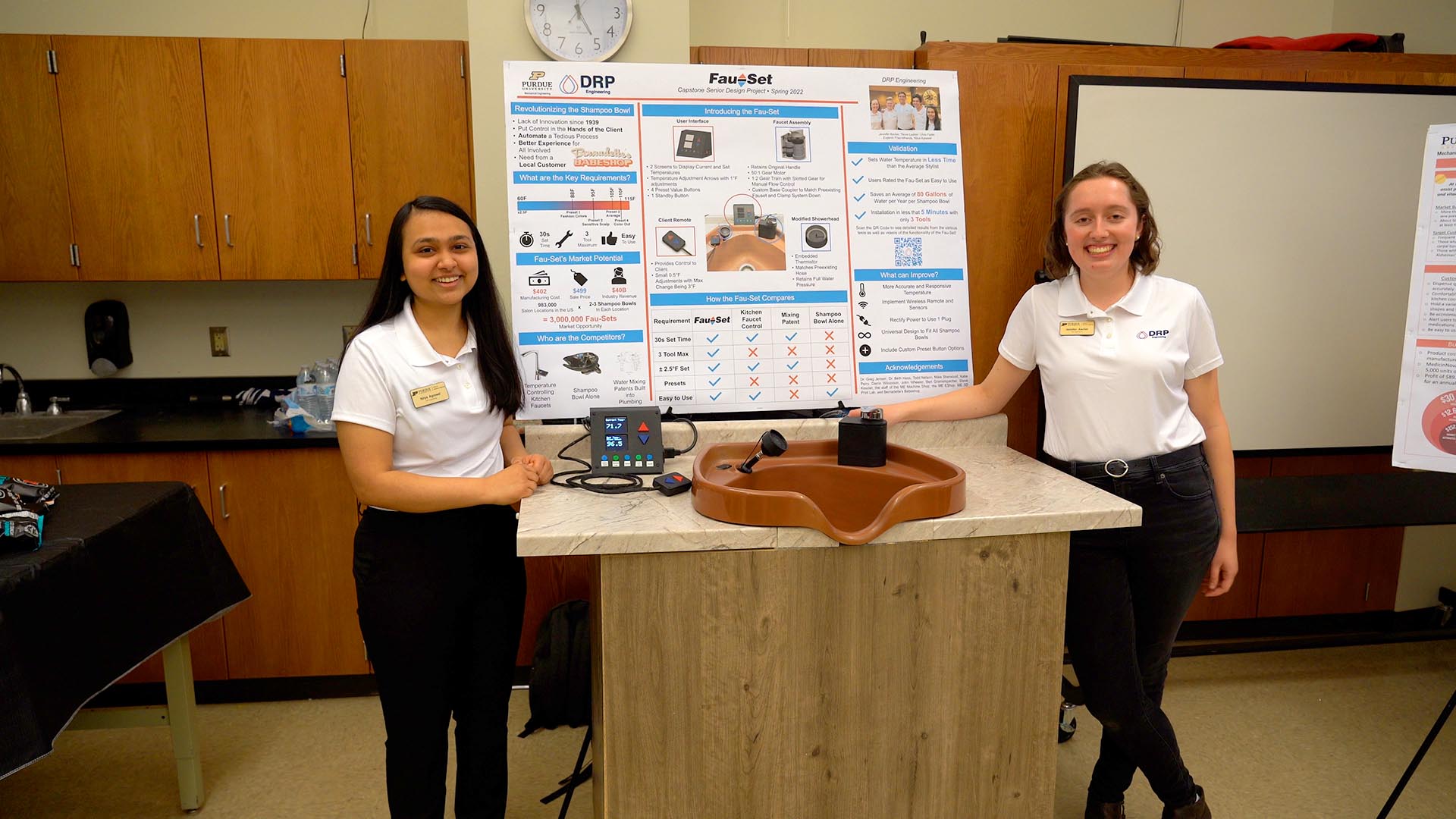

2nd Place: DRP Engineering, Jennifer Ascher, Chris Fadel, Trevor Ladner, Nitya Agrawal, Eugenio Frias-Miranda. Hair salons in the US are a nearly $40 billion industry. Shampoo bowls are present in the vast majority of salons, but have seen little innovation since they were first patented in 1939. Working with a local hair salon, DRP Engineering has created the Fau-Set, an industry-leading product to enhance client experience by automating the water temperature selection process for shampoo bowls without impacting existing plumbing. Setting the perfect water temperature is a tedious but necessary process to ensure client relaxation and the efficacy of the hair products. In current shampoo bowls, the client and stylist must constantly communicate about the preferred water temperature. The Fau-Set eliminates this feedback loop with a user interface for the stylist to select different temperatures for different products and a remote so the client can make adjustment for their own comfort. Using a temperature sensor, a motor adjusts the faucet valve to match the desired output. It costs only $499, less than all of its competitors, and has an easy installation process that requires removing only one set screw from the original faucet. The Fau-Set is the next step in faucet innovation, by saving stylists’ time and empowering clients to take control of their own salon experience.

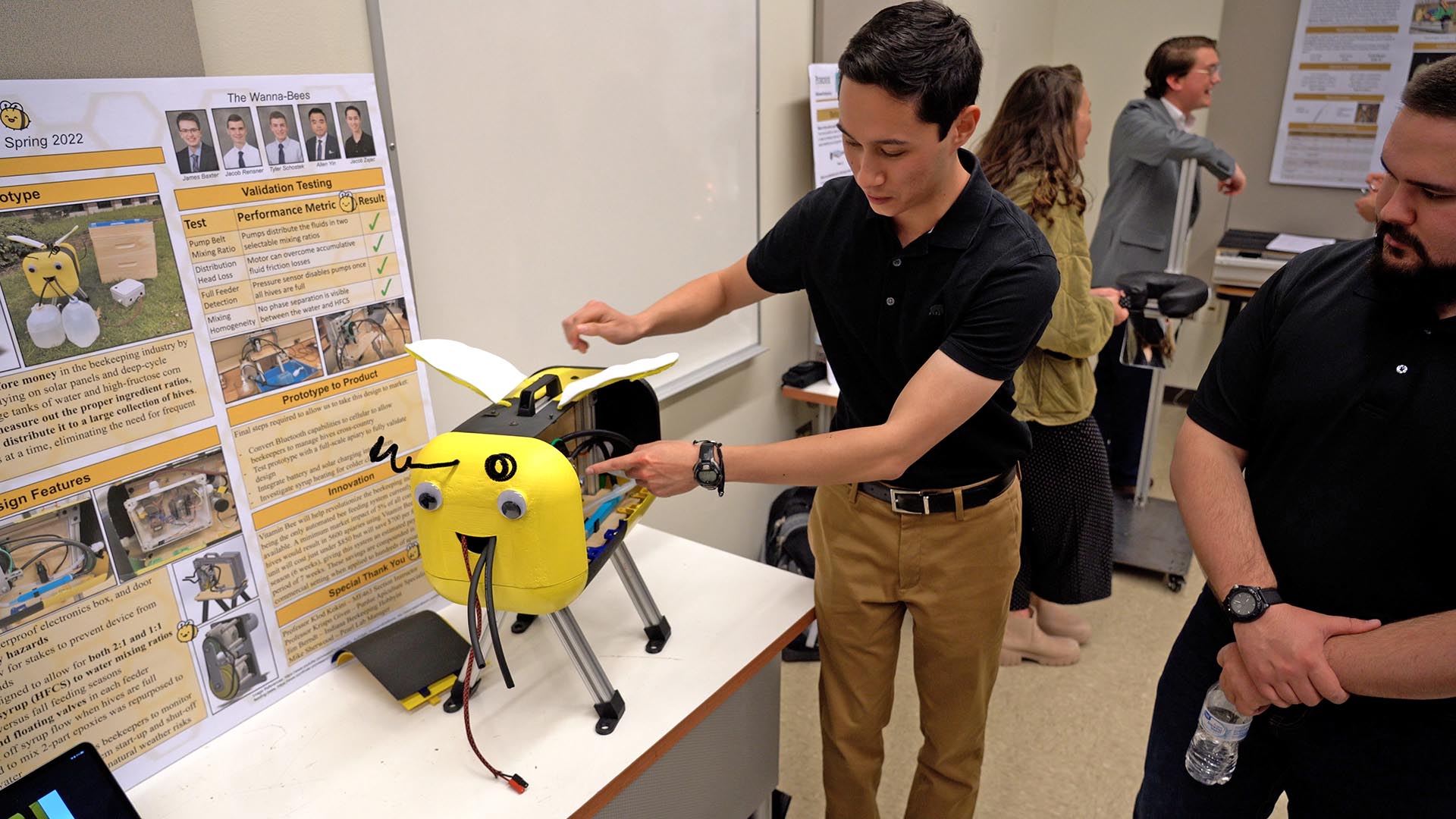

3rd Place: Wanna-Bees, James Baxter, Jacob Rensner, Tyler Schostek, Siyuan (Allen) Yin, Jacob Zajac. To keep up with pollination efficiency demands and ensure bee survival in harsh winter climates, commercial beekeepers often feed honeybees food supplements. This means bees spend more time pollinating crops and less time producing honey as food. However, a major problem lies in the vast amounts of time beekeepers have to spend making the sugar-water (syrup) mixture and individually distributing it to up to 10,000 hives spread across hundreds of miles. Vitamin Bee aims to save time and therefore money in the beekeeping industry by automating the feeding process. Relying on solar panels and deep-cycle batteries for power alongside large storage tanks of water and high-fructose corn syrup, Vitamin Bee will automatically measure out the proper ingredient ratios, mix the syrup until homogenous, and distribute it to a large collection of hives. The device will run for several months at a time, eliminating the need for frequent on-site visits.

Best Engineering Award: Medicinnovations, Matthew Calisto, Daryl Chan, Brian Fielder, Sara Hawe, Brian Li, Ben Koszyk, August Shrader. In the US, 50% of people aged 70+ take at least 5 prescription medications. This task can be easily forgotten with multiple schedules to manage and with memory impairing ailments. With age comes more health complications that can cause difficulty opening pill bottles such as arthritis. The best existing solutions to this problem include pill dispensers/organizers, but the ones available on the market are expensive, slow and mostly manual. MedicinNovations’s product, the SimPill, aims to refine the strengths and improve upon the drawbacks of these existing solutions. The SimPill allows users to program their exact medication or vitamin schedule and to receive alerts. Prior to the dispensing time, the SimPill will retrieve every required pill and have them prepared in holding zones. Users have the option of dispensing the retrieved pills all at once, or only specific pills as desired for a need-to-need basis. With these innovations, SimPill plans to help make healthcare easier and more efficient for the elderly.

About the Malott Innovation Awards

About the Malott Innovation Awards

The Malott Innovation Awards are supported by an endowment created in 2007 by Thomas J. Malott (BSME '62, HDR '02), to foster an innovation culture among Purdue Mechanical Engineering students. Malott is the former president, CEO and director of Siemens Energy and Automation. His career included executive positions with Parker-Hannifin and the Ransburg Corp., as well as serving on several corporate boards. He was an inaugural member of the Purdue Foundation Development Council and was awarded the Outstanding Mechanical Engineer and Distinguished Engineering Alumnus awards in 1991 from the university.

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Source: Greg Jensen, jensen23@purdue.edu, 765-496-0214