Malott Innovation Awards showcase student prototypes

The Malott Innovation Awards are the culmination of ME463, Purdue's capstone class for seniors in Mechanical Engineering. Teams of students work closely with faculty members and industry partners to create prototype products, continually refining and improving them using the knowledge from their engineering courses over the last four years. At the end of the semester, the students present their final prototypes to a panel of Purdue ME alumni who work in various industries; this panel selects the award winning teams.

Because of the restrictions of the COVID-19 pandemic, only some of the teams were able to work on their projects in person (socially distanced). Others completed their projects entirely remotely; some of them in multiple time zones, and even in multiple countries! Teams presented their prototypes to the panel of judges through Powerpoint. This semester's teams came up with numerous innovative ideas, from a wheelchair for the performing arts, to a machine that oils the gears of a bicycle, to a rotating wind tunnel.

1st Place: Performing Arts Wheelchair (Team All World’s Stage): Alexandra Ziolkowski, Peter Callahan, Dongwei Bai, Zihao Lin, Grant Goldate, Lohith Rao. The world of theater and performing arts is currently not very accessible for actors who require wheelchairs for mobility. A current limitation is the smaller range of motion these actors have for completing choreography, as well as the challenges of navigating cramped backstage areas. To address this, the Performing Arts Wheelchair features an innovative holonomic drive system, which utilizes omnidirectional wheels. This allows our end-user to move in any direction (forward, backward, diagonally, side-to-side), as well as a zero-degree turning radius. Additionally, because the wheelchair is designed specifically with performers in mind, it integrates additional features based on actors’ priorities, such as the ability to change the seat height via a scissor lift, a small footprint, and a bracket designed for attaching props to the back of the chair.

2nd Place: B-Oiler: Semi-Automatic Bicycle Chain Lubricator (Team Oleum): Jacques Barsimantov, Daniel Romano, Pedro Garcia, Garret Slosser. Chain lubrication is essential to maintain a healthy system and increase performance at the time of biking. This task can be simple, although tiresome and unclean as it requires the user to slowly apply oil to each chain roller. To tackle this problem, team Oleum decided to create the B-Oiler. This simple yet novel device allows cyclists to put oil on their chains in less than 10 seconds while also minimizing oil spillage on the surroundings. The way the B-Oiler parts are assembled is what makes this device unique: an inner oil tank, around which an outer custom-made sprocket rotates, allowing oil to travel only when the chain rollers meet the valleys of the sprocket teeth. Moreover, the B-Oiler can be extended to any machine that requires constant chain lubrication, thus greatly enhancing its market potential.

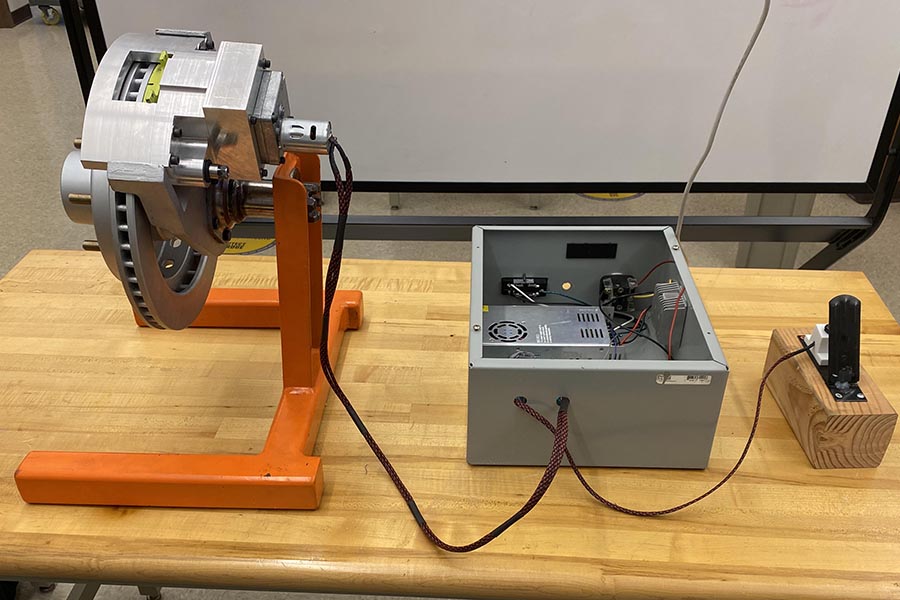

3rd Place: Electric Trailer Braking System for TRP International (Team Pump the Brakes): Frank Muehleman, Brenden Meyer, Blake Larson, Tanner Skrove, Sam Rudder, Dillon Moreland. The current standard for trailer brakes is either hydraulic disc brakes – which are complex and expensive, but have high braking force; or electric drum brakes – which are simple and cheap, but lack the braking force of hydraulics. Our mission was to design a new trailer braking system for TRP International that incorporates their current axle, rotor, and caliper mount from their 7,800 pound- force braking system, while eliminating hydraulics in favor of an electromechanical system. Trailer brakes are particularly relevant now because, despite COVID-19 restrictions, 70% of boat dealers nationwide reported increased sales in spring 2020. With this increase in trailer sales, there is opportunity for a new trailer braking system that will be both cheaper and more reliable than the current standards. Our solution is an electric disc brake that turns rotational motion into linear motion by using a power screw to move a piston into the brake pads, which clamp around the rotor to produce braking force.

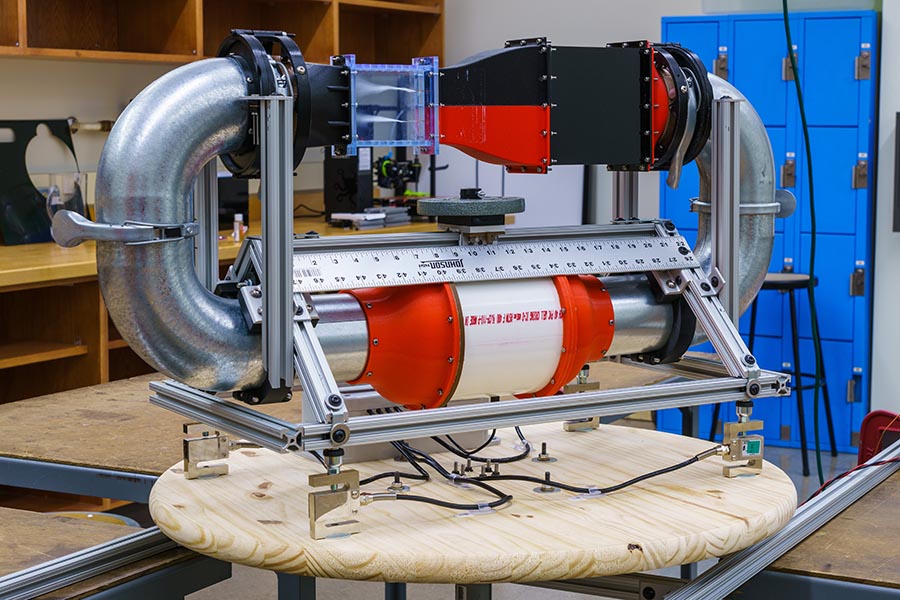

Best Engineering Prize: Rotating Wind Tunnel Design (Team Fluids in Motion): Nathan Cowin, Alex Galema, Raunaq Kumaran, Cole Kinser, Seanan Lee. Turbulent flows in rotating systems play a key role in engineering applications and physics. However, the effects of rotation on the interaction between Coriolis force and centrifugal force is not well understood. The team developed a closed-loop wind tunnel with a rotatable test section, and it will be mounted onto an existing rotating platform in Herrick Labs to study its turbulence, mean flow features, and solid boundaries. The team focused on developing a test section that can be rotated around its longitudinal axis and a control system for statically and dynamically balancing the wind tunnel. A 1/5th-scale model was constructed to validate the design and the scaled model combined with a robust CAD model will serve as the basis for full-scale development.

About the Malott Innovation Awards

About the Malott Innovation Awards

The Malott Innovation Awards are supported by an endowment created in 2007 by Thomas J. Malott (BSME '62, HDR '02), to foster an innovation culture among Purdue Mechanical Engineering students. Malott is the former president, CEO and director of Siemens Energy and Automation. His career included executive positions with Parker-Hannifin and the Ransburg Corp., as well as serving on several corporate boards. He was an inaugural member of the Purdue Foundation Development Council and was awarded the Outstanding Mechanical Engineer and Distinguished Engineering Alumnus awards in 1991 from the university.

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

Source: Greg Jensen, jensen23@purdue.edu, 765-496-0214