High school student visits Purdue to create heart-pumping soft robot

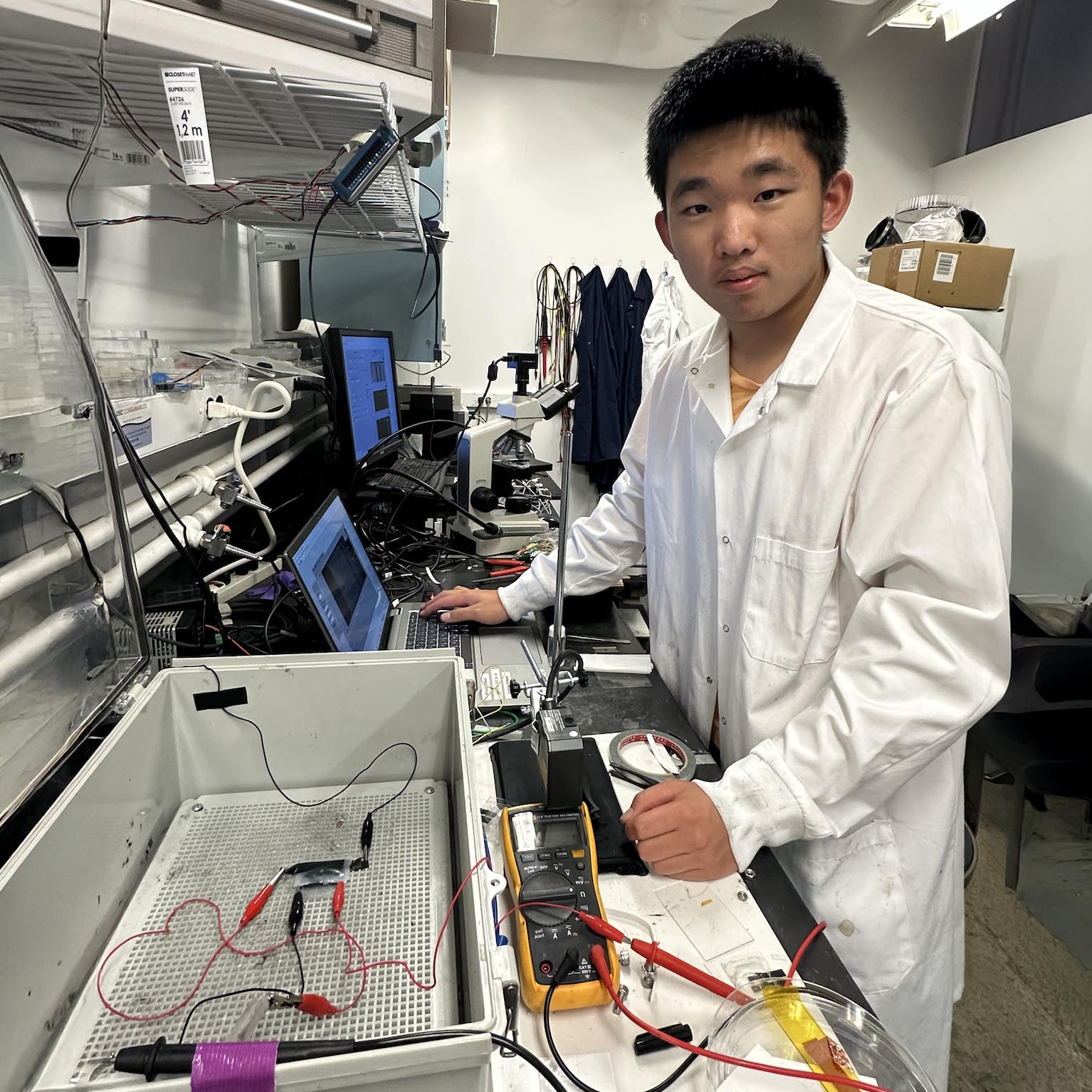

Evan grew up in San Jose, California. Like many engineering students, FIRST Robotics was his gateway into learning about science and technology. “I started doing FIRST in about the 3rd grade,” he said. “Eventually I started branching out and building robots on my own.”

He particularly focused on soft robotics, reading multiple papers on the subject and then building his own trial-and-error projects in his parents’ garage. That’s when he found Alex Chortos, assistant professor of mechanical engineering at Purdue. His research group focuses on soft robots, actuators, and sensors — especially those designed for human-machine interfaces.

“I stumbled across one of his papers about shape-morphing robots,” Zhang said. “We didn’t know each other, but I reached out anyway and asked some questions. He was super supportive.”

“I was very impressed with his grasp of these complex concepts at such a young age,” said Chortos, who has taught high schoolers about 3D printing at Purdue and throughout the state of Indiana. “He obviously had done his homework.”

After a few more exchanges, Chortos invited Zhang to visit Purdue University in the summer of 2024 to continue his home-spun research in a real university robotics lab.

Heartbeat of Robotics

Heartbeat of Robotics

The project they chose to pursue involved HASEL (hydraulically amplified self-healing electrostatic) actuators. Developed at the University of Colorado at Boulder in 2018, these devices use pouches of dielectric liquid which contract like muscles when a voltage is applied.

“I wanted to see if we could 3D print these HASEL actuators,” Zhang said. “Prof. Chortos had a DIW [direct ink write] 3D printer, which enables you to print using semi-liquid materials. That’s something I couldn’t do in my parents’ garage!”

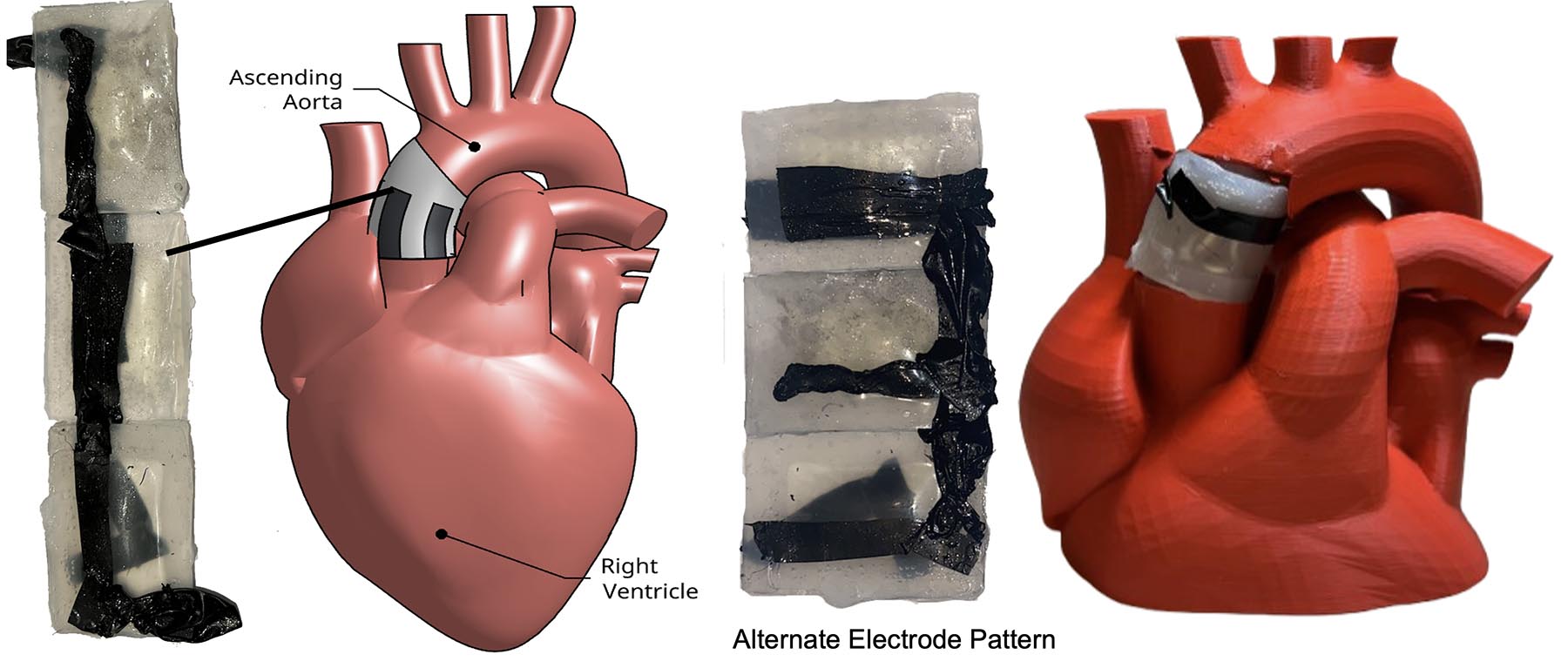

After that first summer, Zhang began to explore potential applications for the actuator he had built. Returning to Chortos’ lab in the summer of 2025, they settled on designing a ventricular assist device (VAD), a biomedical device for patients whose heart muscle needs a boost.

“Traditional VADs have rigid parts that cause a lot of complications,” Zhang said. “So we determined to apply these HASEL actuators to a soft device that could be custom-printed to each individual patient’s heart.”

To simulate the requirements of a real-world VAD, Zhang 3D-printed an analog heart with similar material properties. They attached sensors to measure the energy applied, strain, directionality and frequency. After several iterations, they fabricated a soft custom actuator which exceeded the design specifications of a real-world VAD.

But they weren’t done. “I worked on this project for two years, and I wanted to share it with people,” Zhang said. “Prof. Chortos helped me find an academic conference where I might present this research, and he helped me with the writing and submission process. They accepted it!”

Zhang presented his research remotely at the ICMSR 2025 (International Conference on Mechatronics Systems and Robotics) in Singapore, and received an award for Best Presentation.

“This is pretty remarkable, considering that all the other presenters were professors or Ph.D. students,” said Chortos.

Zhang is planning to attend college and study mechanical engineering and economics. But he’ll always remember how his first taste of academia came about as the result of an out-of-the-blue email.

“To be honest, professors are super busy, and typically if you email a professor you don’t know, you don’t expect that they’ll ever reply,” Zhang said. “The fact that Prof. Chortos was willing to respond in the first place is amazing. That he was so supportive enough of my work to invite me to his lab is just super impressive, and I’m really thankful for him.”

Source: Alex Chortos, achortos@purdue.edu

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374

3D-Printed HASEL Actuators With Integrated Fluidic Piezoresistive Pressure Sensor for Cardiac Assist Applications

Evan Zhang, Alex Chortos

ABSTRACT: This work presents a fully 3D printed Hydraulically Amplified Self-Healing Electrostatic (HASEL) actuator integrated with a soft piezoresistive force sensor for cardiac assist applications. The actuator is fabricated via direct ink write (DIW) 3D printing, enabling precise and personalizable construction of elastomer shells, soft electrodes, and liquid dielectric cavities. A fluidic piezoresistive sensor is integrated for monitoring of pressure output while preserving the actuator’s compliant properties. The actuator achieves up to 87.9% strain with rapid response and repeatability up to 7.5 Hz. The sensor also demonstrates minimal hysteresis due to the fluidic reset mechanism, and it exhibits a clear correlation between applied force and resistance when coupled with the actuator. This self-sensing system enables closed-loop control through correlating voltage, resistance, and force and meets the performance requirements for mechanical support of the heart. Compared to existing VADs, this approach offers improved bio-compatibility, adaptability, and sensing. This work establishes a foundation for self-sensing soft robotic systems for future biomedical devices.