The smart way to make smart bandages

“There’s nothing like this out there,” said Ziheng Wang, fourth year PhD student in mechanical engineering. “We developed a low-cost and efficient solution to long-term wound care.”

Some wounds take weeks or even months to heal, and doctors typically track infection by visual inspection or lab testing, a process that can be time-consuming and prone to human error. That’s why Ziheng Wang and Chi Hwan Lee, professor of biomedical and mechanical engineering, created smart bandages that continuously monitor wounds for signs of infection.

The bandages not only protect wounds from external elements but also track key biomarkers such as pH, temperature and humidity using colorimetric sensors. These small sensors use color-changing inks to detect early signs of infection. High pH and elevated temperatures in wounds often signal infection, while low temperatures can indicate poor blood flow. Having excess moisture in the wound can encourage bacterial growth, while dryness can delay healing.

“The sensors can be printed on various fabric dressings,” said Wang. “Some sensors change once, while others change back and forth, allowing us to see both the history and the current status of the wound.”

As a Purdue faculty member since 2015, Lee has developed a broad range of wearable medical devices, from prosthetics to smart contact lenses — and even Bluetooth health sensors for horses. But this smart bandage is notable because it was designed for ease of manufacture.

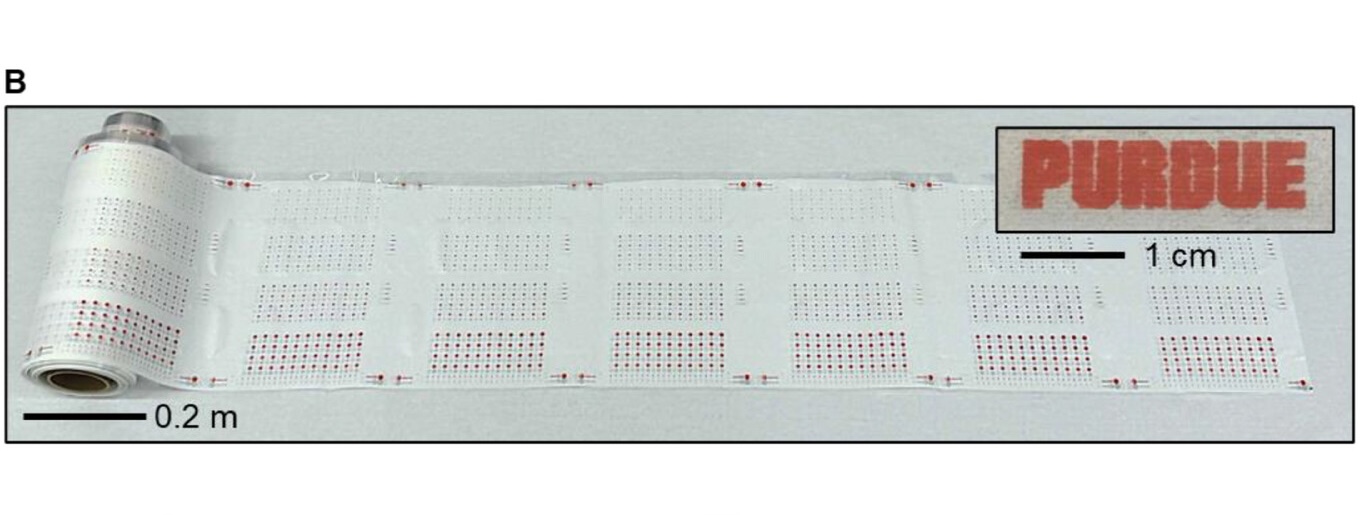

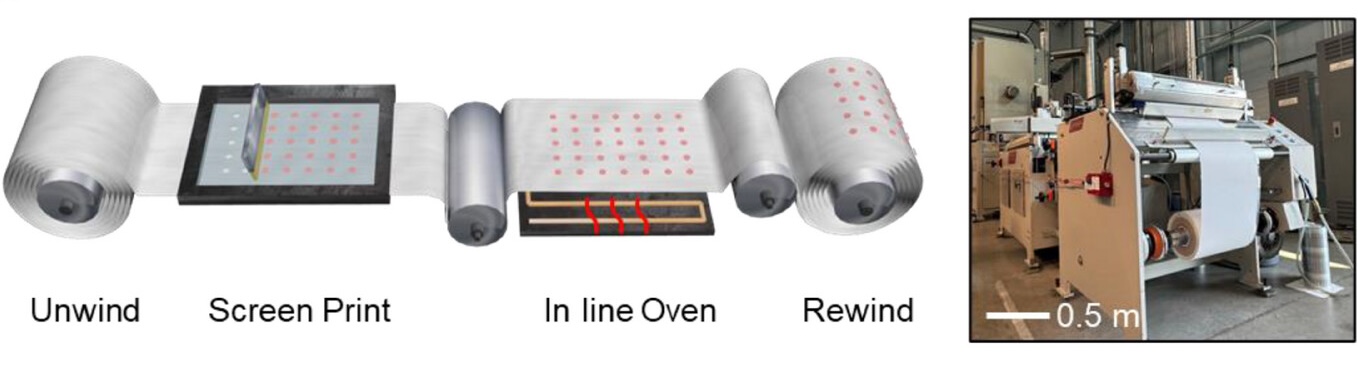

To make the bandages affordable and widely available, the team used roll-to-roll manufacturing, a technique similar to newspaper or sticker printing. The process begins when nonwoven fabric is wound into a roll and placed on the machine. As the roll unwinds, a screen printer applies the colorimetric sensors, and an in-line oven dries and cures the ink. The material is rewound, then cut to the needed size. Each bandage is multilayered, with sensors printed individually and a protective layer added to minimize blood absorption and ensure clear visibility of color changes.

To confirm the sensors’ accuracy, the team conducted a range of experiments on mice, with both normal and infected wounds. After 14 days, the smart dressings showed normal readings on the healthy wounds and elevated temperature and moisture, along with visibly larger wound areas, on the infected wounds.

To further confirm the colorimetric sensors were accurately detecting infection, researchers collaborated with Young Kim, professor of biomedical engineering, to develop a machine learning model to accurately read the colors. “We were able to use a smartphone to take a picture of the bandage, and the model would read the colors and confirm the wounds status.”

These experiments confirmed that the bandages can successfully detect early signs of infection, showing strong potential for real-world use. Their work was conducted in collaboration with Dr. Murtuza Peerbhai of Monticello Podiatry LLC in Indiana and Prof. Chandan K. Sen at the McGowan Institute for Regenerative Medicine, as well as the Departments of Surgery and Plastic Surgery at the University of Pittsburgh, to translate the technology toward clinical applications.

So, what’s next? “We want to add more sensors in the future,” said Wang. “Sensors that can help diabetics by tracking glucose, or ones that are specifically targeted for women’s health. We also want to begin testing these bandages on humans.”

Roll-to-roll manufacturing enables mass production of smart bandages at a low cost, offering an affordable solution for long-term wound care. These bandages could be used in hospitals, clinics, and even provided to patients for at-home treatment — potentially transforming the future of wound care.

This production method has a provisional patent filed with the Purdue Innovates Office of Technology Commercialization. For more information contact Patrick Finnerty, pwfinnerty@prf.org and reference code 2025-LEE-71004

Roll-To-Roll Production of Smart Dressings for Wound Monitoring

Ziheng Wang, Yujin Ahn, Semin Kwon, Tianhao Yu, Yumin Dai, Julia Walsh, Joo Hun Lee, Sang Mok Park, Seul Ah Lee, Murtuza Peerbhai, Chandan K. Sen, Hyowon Lee, Young L. Kim, Hyunjoon Kong, Chi Hwan Lee

https://doi.org/10.1002/adhm.202501998

ABSTRACT: Chronic wounds require real-time monitoring to assess wound status and prevent complications. While colorimetric sensors provide a user-friendly, equipment-free approach with visible feedback, their clinical adoption is hindered by limited scalability, poor integration with commercial dressings, and susceptibility to interference from wound exudates—factors that have largely confined existing systems to laboratory research and prevented their practical use in clinical settings. Here, the first roll-to-roll production of smart dressings at a large scale and high throughput, with colorimetric sensors for real-time and historical wound monitoring is presented. This method enables high-throughput production, achieving over 10 impressions per minute on formats up to 50 cm × 50 cm, using biocompatible inks for precise multi-layer printing. In situ testing on a 14-day mouse wound model demonstrates their ability to detect early signs of infection, validating their functionality in physiologically relevant conditions. This study addresses the manufacturability gap in colorimetric wound sensing, providing a scalable, cost-effective, and clinically translatable solution for both clinical and home use.

Writer: Julia Davis, juliadavis@purdue.edu