Railside Robotics: Build it, destroy it, then build it again!

If you’ve ever watched a Battlebots competition on TV and said, “I want to do that” — now you can! Railside Robotics gives Purdue students the opportunity to design their own combat robots: build them, compete with them, and then watch them be torn to shreds.

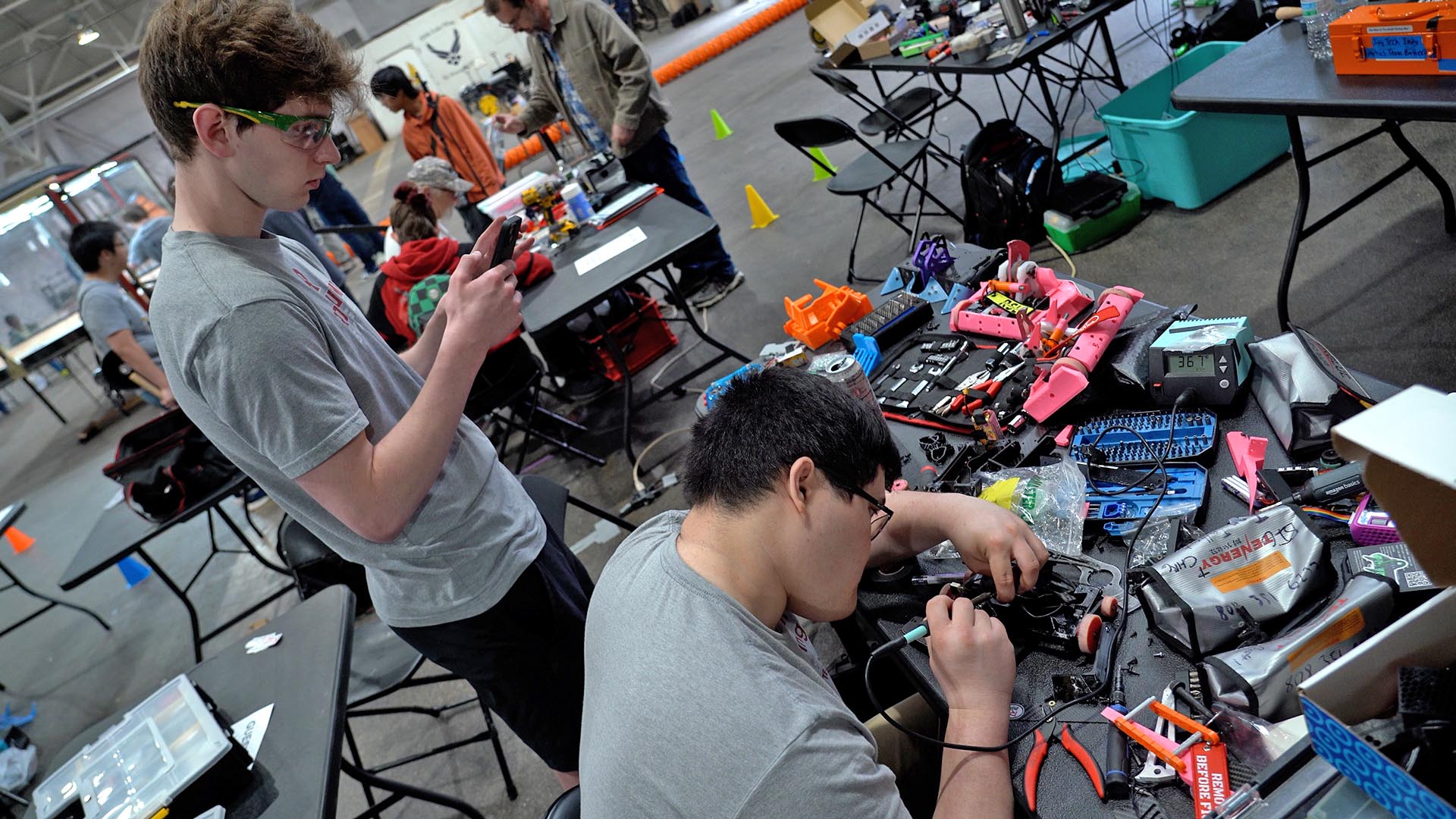

At the inaugural Railside Rumble in April 2025, student robotics teams from across the Midwest fill the Purdue Armory. The “arena” stands in the center: a fully-enclosed polycarbonate box with a plywood playfield at eye level. To the right side: table after table of spare parts, soldering irons, toolboxes, and various bits and pieces discarded from embattled bots.

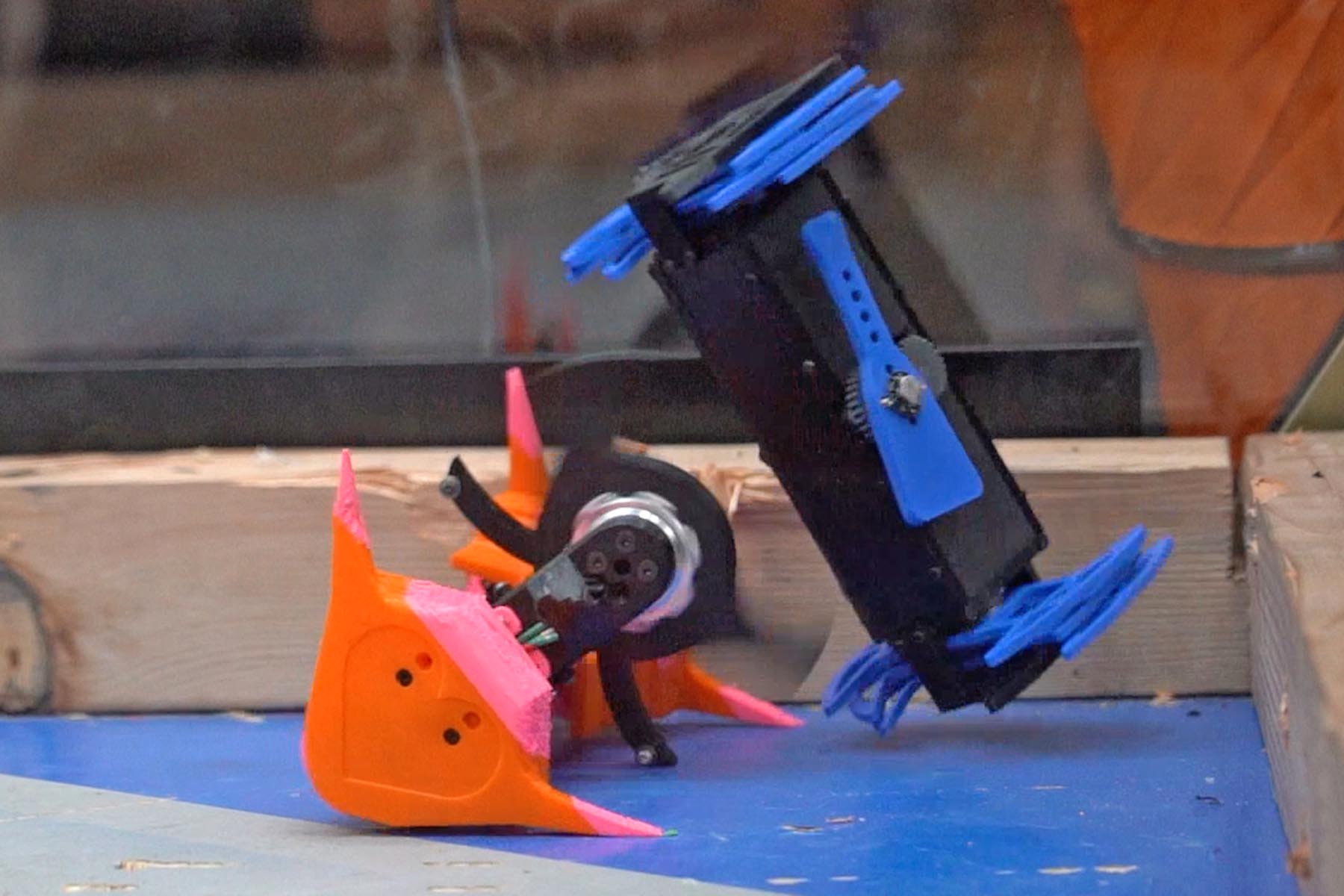

“What we have are basically a bunch of robots tearing each other to shreds,” said Raymond Frazee (BSME ’25), then president of Railside Robotics. “Your goal is to control and damage your opponent as much as possible, while simultaneously not being controlled or damaged by them.”

To accomplish this, student bot builders try a little bit of everything. Some spin deadly sharp metal blades at high rates of speed. Others use lifting arms to topple their opponents. Some are tiny, while others have arms that extend outwards a great distance. Some even eschew wheels, opting for a “creeping spider” approach for locomotion.

“Targeting wheels is actually very smart,” Frazee said. “If your opponent has exposed wheels, you want to go for those first. Your opponent could have the best and flashiest weapons in the world, but if their robot can’t drive, they’ve lost the match.”

After a few chaotic minutes, one bot usually gives up the ghost, and the match is over. Students “safe” the weapons on their bot before retrieving them. Volunteers then use brooms to clean up the playfield — sweeping up a hilarious mix of 3D-printed plastic bits, electronics, and chunks of the plywood playfield chipped away by overly zealous attacks.

Start your printers

Railside Robotics is a relatively new club at Purdue, but has skyrocketed in popularity. One reason is its open-door policy for newcomers.

“All experience levels are welcome,” Frazee said. “Most of the people competing today had no experience at all when they joined.”

Most new members build “plants” (short for “plastic ants.”) These robots are less than one pound, and typically 3D-printed with PLA plastic. Students can experiment with these “ants” in practice rounds, without worrying about losing anything precious or expensive. If a part breaks or doesn’t work, you 3D-print something else.

More experienced bot builders advance to the “beetle” class, where the robots can weigh up to 3 pounds.

“I went to their callout, and I just loved the energy of the group,” said Justin Sprangers, who joined Railside Robotics last fall. “As a freshman, being able to just dive in and have my own projects, while learning from knowledgeable people, is big. I never thought I would be soldering and learning mechanical design and getting all this experience so early.”

Sprangers' prototype, Stark, is based on Tony Stark’s arc reactor from the Iron Man films. It has creeper legs, and a spinning ring on the outside. At the Rumble, the purely-plastic Stark prototype stays in the practice ring; but Sprangers says he is learning from the other students about ideal materials and design techniques that can be integrated into version 2.

“It’s been an awesome hands-on learning experience,” he said. “Having a project you can say is yours is a big thing for me.”

For Jasper Uradnicek, his bot has been years in the making.

“This is Bars, which we’ve developed through many iterations over two semesters,” he said, holding a black 1-pound bot with a sharpened blade out front. “Our main weapon is a spinning bar made out of AR 500 steel, which is what they use to make targets at the gun range.”

But it’s not all twisted metal. Bars’ secret weapon is actually defensive — a layer of yellow fins made of rubberized TPU thermoplastic. “These are meant to intentionally wiggle around when they take impacts,” he said. “That makes our bot very difficult to damage.”

Design for maintenance

All the bots at the Rumble have one thing in common — they will all get repaired at some point.

“We heavily push design for manufacturability, and design for maintenance,” said Frazee. “You need to build in the ability to make spares and quickly replace things.”

At the repair tables, there is just as much activity as on the playfield. Students are soldering loose wires, sharpening blades, swapping out parts or 3D-printing new ones. “The best thing you can do is to have a robot that’s configurable,” Frazee said. “Swap out different kinds of weapons, or lifting forks, or arms. Even modular armor — depending in your opponent, you may need more protection on the front, the sides, or the top.”

The Railside Rumble was a tremendous success, and the club intends to make it an annual event. As always, Railside Robotics is open to all students, regardless of major or experience level.

“If you want to be a part of the next big thing at Purdue,” Frazee said, “having a lot of fun and learning a lot about engineering design principles, you should really consider Railside Robotics.”

Railside Robotics

Website: https://sites.google.com/view/railsiderobotics/home

Instagram: https://www.instagram.com/railsiderobotics/

LinkedIn: https://www.linkedin.com/in/railside-robotics-2607a1271/

Email: rlsdrbts@purdue.edu

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374