Purdue's Mechanical Engineering Building represents more than a century of history

Humble Beginnings

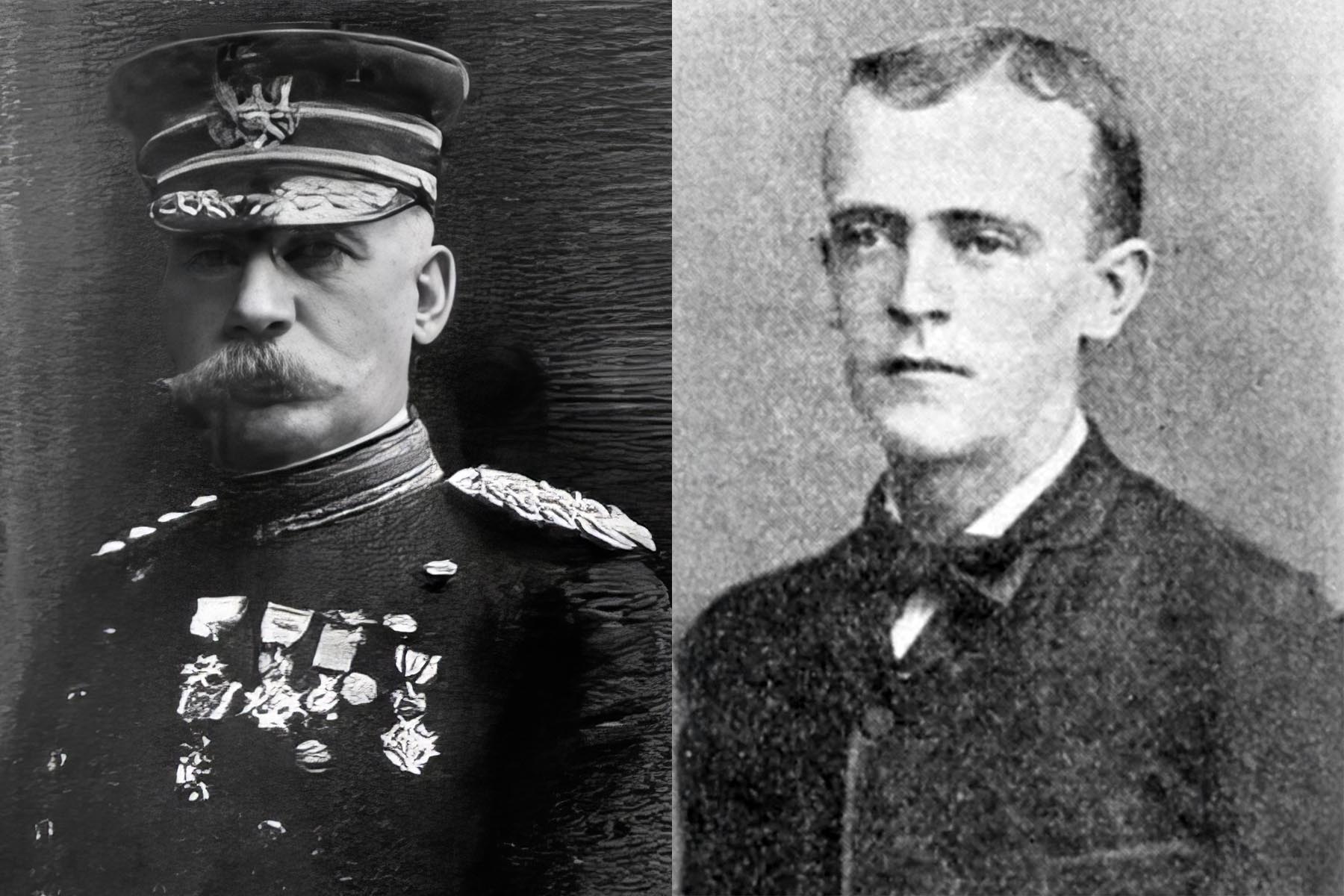

Purdue’s roots go back to the Morrill Land-Grant Act, signed into law by Abraham Lincoln in 1862, which helped to create educational institutions teaching “agriculture and the mechanic arts.” At the time, engineering was only taught in military academies. Purdue soon established the School of Mechanical Engineering and hired its first professor, Lt. William Hamilton of the US Army. One student enrolled, Charles L. Ratliff, who completed Purdue’s first mechanical engineering degree in 1885.

All Aboard

At the time, steam power was the height of technology — and Purdue was about to become the Silicon Valley of steam.

A defining moment in the history of Purdue University took place in September 1891, with the arrival of the Schenectady No. 1 — the first locomotive ever to be studied under laboratory conditions. The steam engine’s wheels ran in place on a treadmill at fantastic speeds, while measurement tools generated mountains of data on boiler efficiency, speed, load bearing, steam pressure, valve proportions, and more. (A model of this laboratory, built for the Chicago World’s Fair in 1893, is currently on display in the Atrium of the Mechanical Engineering Building).

In the highly competitive railroad industry, Purdue hosted the only neutral testing ground in the country. Over the years, they secured a series of newer locomotives, Schenectady No. 2, 3, and 4. Many railroad companies even brought their own locomotives to Purdue, taking advantage of Purdue’s engineering expertise. Eventually, all Purdue grads past and present would embrace this reputation with a nickname: “Boilermakers.”

One Brick Higher

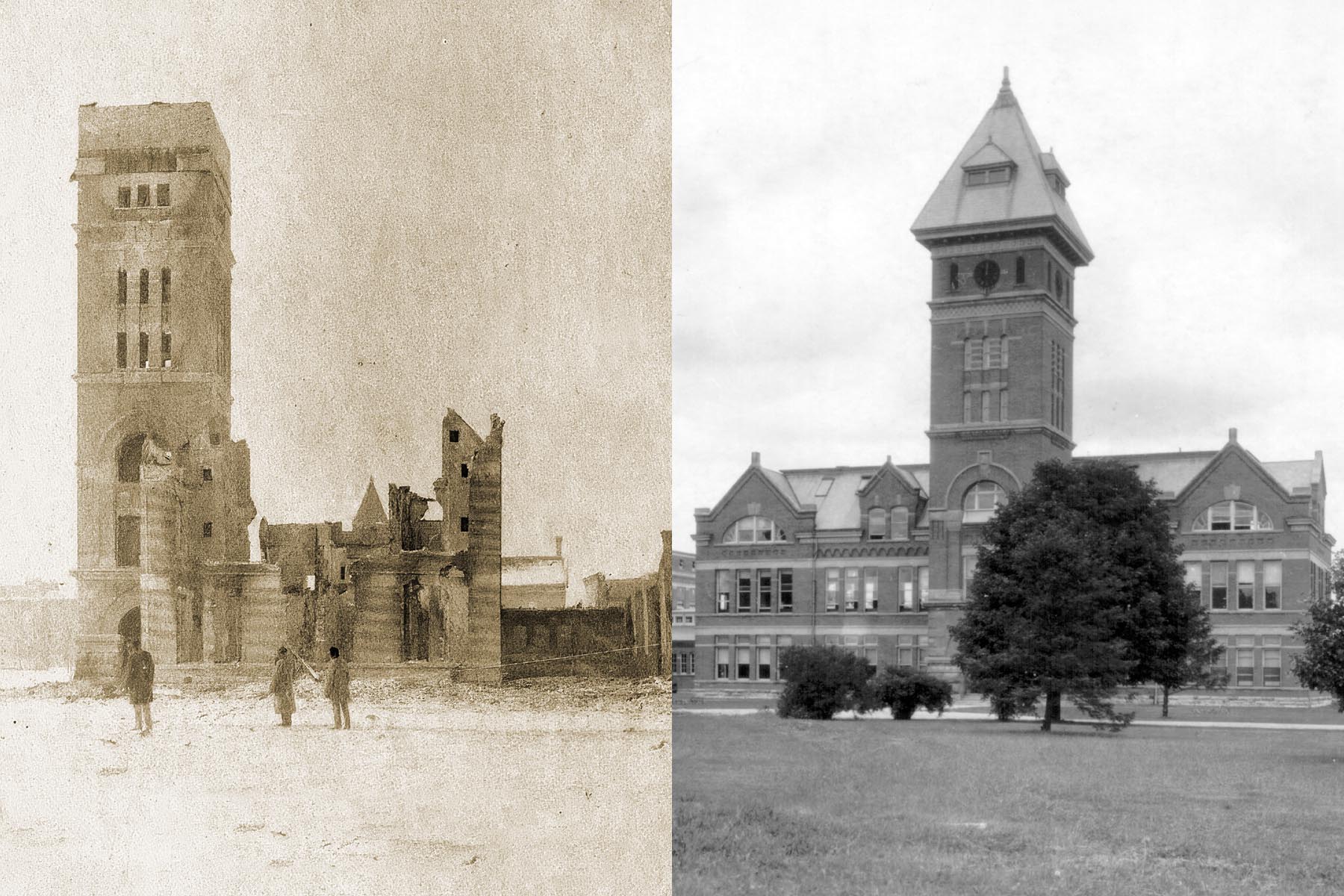

On January 19, 1894, thousands gathered to celebrate the completion of Heavilon Hall — the newest and largest building on Purdue’s campus, and by some measures, one of the most advanced mechanical engineering laboratories in the country. For its opening night dedication, the 140-foot tower was festooned with electric lights, visible for miles. A thousand guests attended a celebratory dance, including Indiana Governor Claude Matthews.

Four days later, an explosion in the boiler room sparked a devastating fire which destroyed the entire complex. With the ashes still smoldering, President James Smart addressed the Purdue community and declared that they would rebuild it “one brick higher.”

President Smart kept his promise. The new Heavilon Hall opened in December 1895, an even more magnificent complex featuring the newest equipment and machinery. It was technically nine bricks higher than its predecessor, including a new clock tower and carillon bells which rang out every hour.

The story of Heavilon Hall demonstrates the resolve of Purdue University’s people to persevere through challenges — a spirit that continues to this day.

Purdue at Wartime

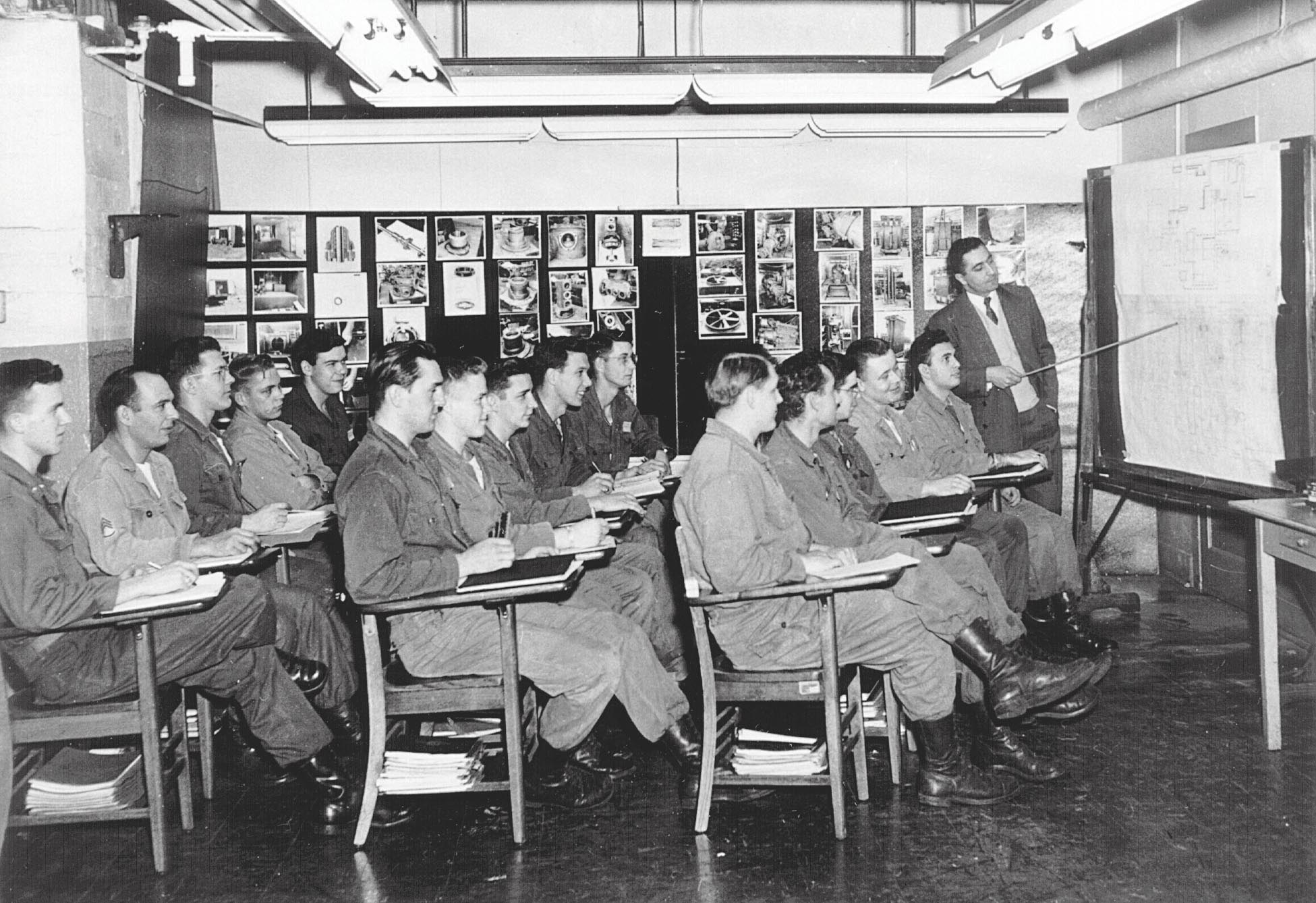

World War II affected the lives of all Americans, and Purdue was no different. In addition to the thousands of students who were called up or volunteered for active duty, the faculty of the School of Mechanical Engineering assisted in the war effort by educating thousands of Army and Navy officers in accelerated engineering programs. During the war, 1,250 Army and 1,250 Navy officer candidates were educated by Purdue Engineering faculty. So many enrolled that Purdue adopted three 16-week semesters to accommodate everyone.

They also undertook research projects focused on ordnance, tanks, airplanes, manufacturing, and more. One of the military’s early issues was its .50-caliber machine gun; when fired in long bursts, its barrel would melt under the intense heat. Because of Purdue’s expertise in thermodynamics, the U.S. Army’s Ordnance Department enlisted the help of Prof. George Hawkins to solve the problem. He set up a machine gun range just north of Ross-Ade Stadium, and fired over a million rounds of ammunition over four years of testing. Hawkins received the War Department’s Certificate of Appreciation for their research.

Start Your Engines

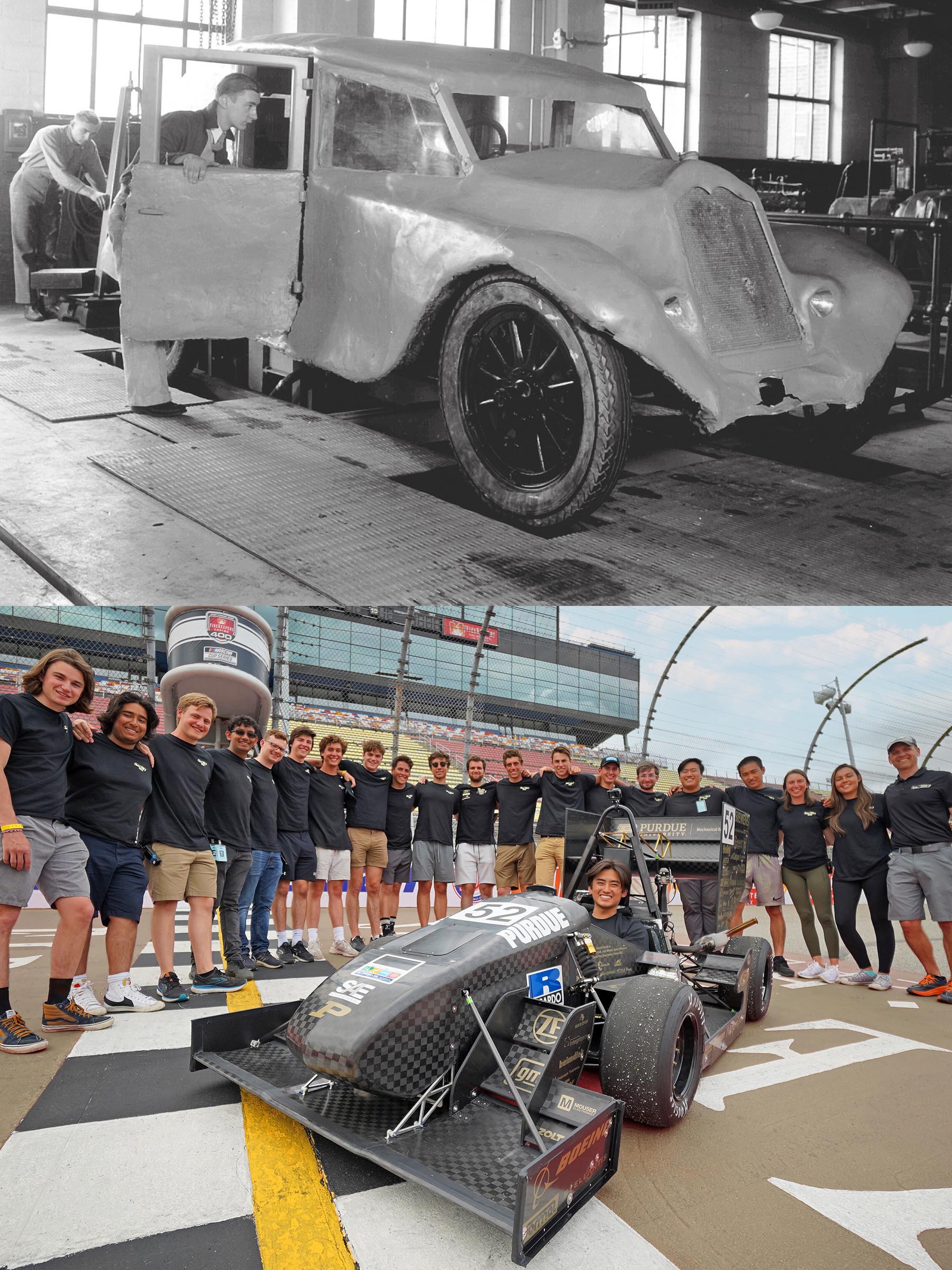

As steam engineering declined in importance, the internal combustion engine became the soundtrack of the 20th century — and Purdue was once again at the forefront of its development. Their 1892 purchase of an Otto Cycle gas engine was the first in any engineering laboratory in the United States. Before long, automobiles and their engines were a core part of the Mechanical Engineering curriculum.

Students formed a Purdue chapter of the Society of Automotive Engineers (SAE) in 1936. Ever since, students have designed and built incredible cars every year as part of Formula SAE, Baja SAE, Formula Electric SAE, and other competitions.

Shoot For The Moon

After World War II, Purdue’s administration also foresaw the vital role of rockets and jet propulsion, and began looking for someone qualified to teach classes in the field. They found their man in Maurice J. Zucrow, who had earned Purdue’s first ever Ph.D. in Mechanical Engineering in 1928.

Zucrow established a small testing facility in a corner of the Purdue Airport, and wrote the first ever textbook on jet propulsion. In the decades since, that simple “rocket lab” has grown into a comprehensive 24-acre complex hosting hundreds of researchers. The Maurice J. Zucrow Laboratories are now the largest academic propulsion lab in the world.

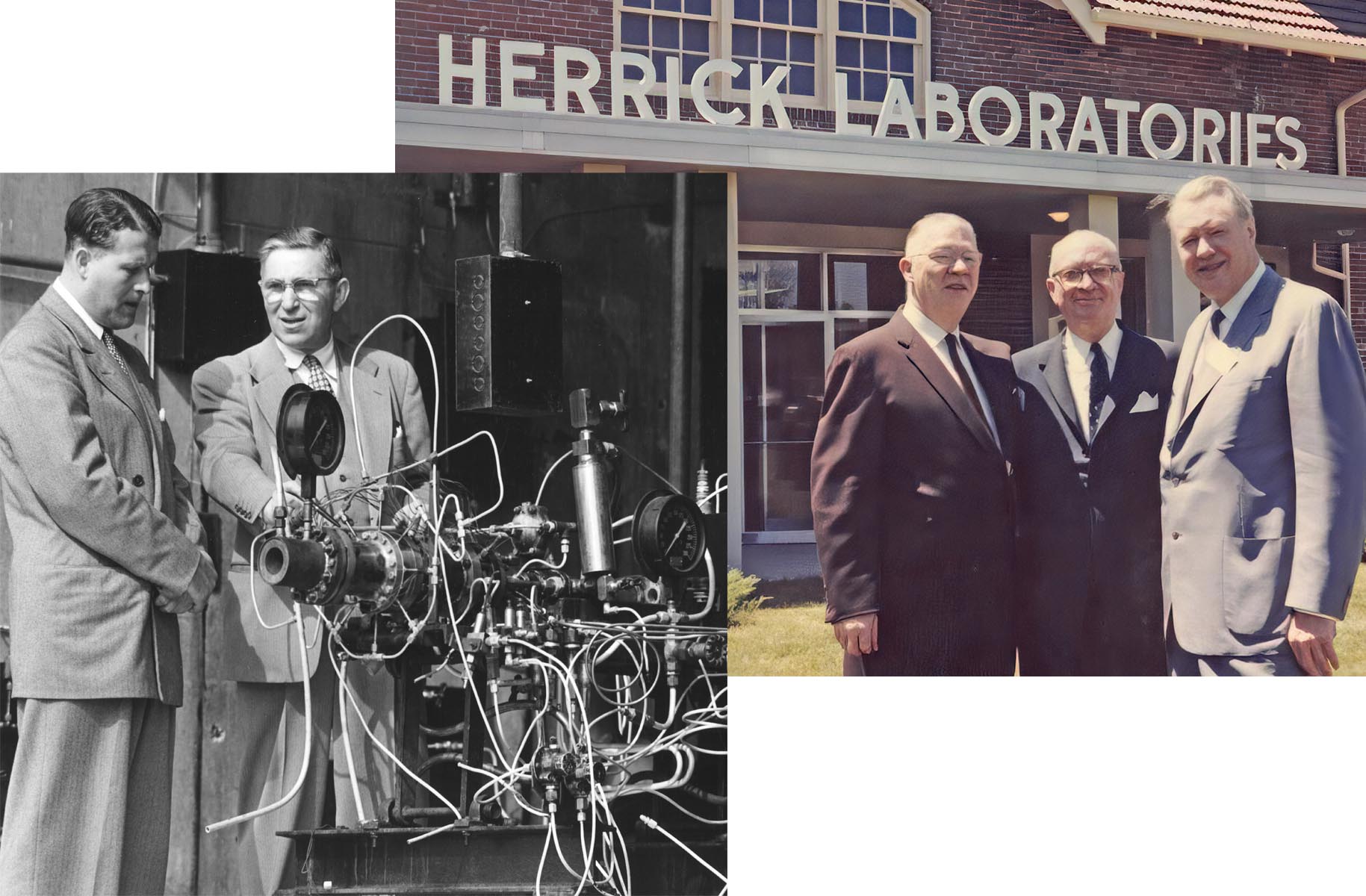

Another Purdue ME external research lab came about in the 1950s, when professor William E. Fontaine had a “cool” idea: a lab where graduate students could work on real-world projects funded by industry partners. Fontaine found a taker in Ray W. Herrick, the founder of Tecumseh Products and a pioneering force in air conditioning. The facility opened its doors in 1958, and Purdue students began collaborating with industry partners to tackle issues around heating, ventilation, air conditioning, and refrigeration (HVAC&R). Today, the Ray W. Herrick Laboratories are home to the largest academic HVAC&R lab in the world.

In Print

Zucrow also became notable for a book. When he first came to Purdue to teach rockets and air-breathing propulsion, there was not a sufficient textbook on the subject. So he wrote his own, based on lectures he gave during World War II. “Principles of Jet Propulsion and Gas Turbines,” published in 1948, became an instant reference for thousands of aerospace engineers worldwide now employed in the new “Space Race.” In fact, a young Neil Armstrong mentioned this book as one reason why he chose to attend Purdue. Zucrow went on to write several more books on propulsion, thermodynamics, and gas dynamics.

It's one of several textbooks authored by legendary ME faculty. Robert W. Fox and Alan T. McDonald taught fluid mechanics at Purdue, but they found the existing textbooks lacking. So in 1973, they collaborated on a new book: “Introduction to Fluid Mechanics.” Its straightforward approach caught on with educators around the world, and it soon became the standard for teaching engineering undergraduates the basics of the field. The book’s 10th edition was published in 2020.

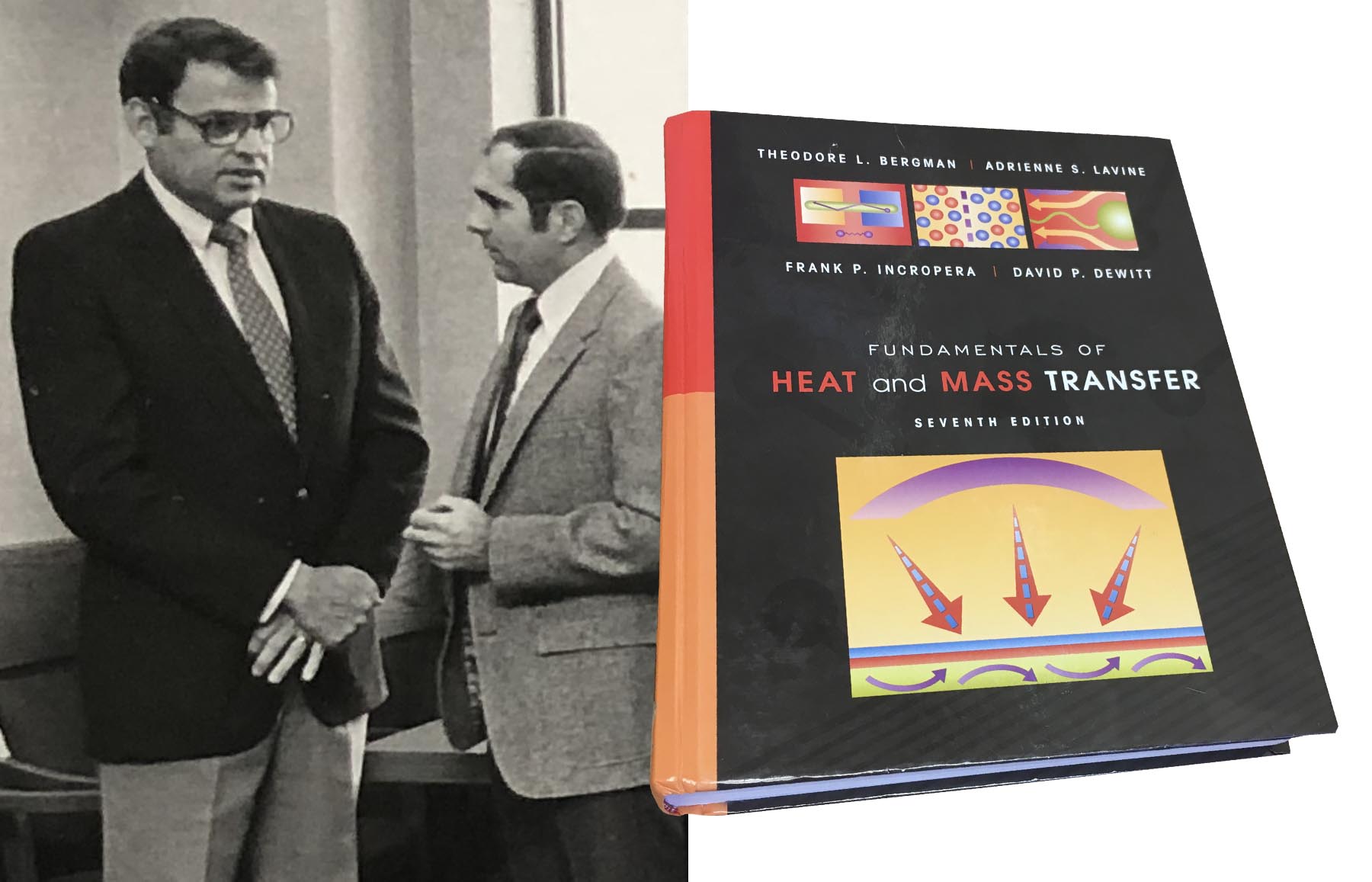

David P. DeWitt and Frank P. Incropera were part of a Purdue’s leading heat transfer department. They felt that students needed a better text to grasp the basic concepts of heat transfer. Together, they worked for six years authoring a book and creating legendary homework problems for each chapter. In 1981, “Fundamentals of Heat and Mass Transfer” was published, and soon became the “bible” of heat transfer. It was translated into multiple languages, and found its way onto engineers’ bookshelves around the world. The 8th edition was published in 2020.

Boilers Abroad

In the 1990s, studying abroad was not a priority for Mechanical Engineering students; less than 1% participated in any international activity. That changed in 2003 with the creation of GEARE, the Global Engineering Alliance for Research and Education. This program offered students the opportunity to study abroad, gain work experience abroad, earn a Global Engineering Studies Minor, and still graduate on time. Today, nearly 40% of Purdue ME students participate in an international experience — taking full advantage of the global nature of engineering in the 21st century.

It's also part of Purdue ME’s emphasis on G.R.I.T.: Global, Research, Industry, and Teams. These aspects of experiential learning are key to shaping the well-rounded Boilermaker engineers of the future. Students who participate in all four receive an award signifying “True GRIT!”

Innovation in Action

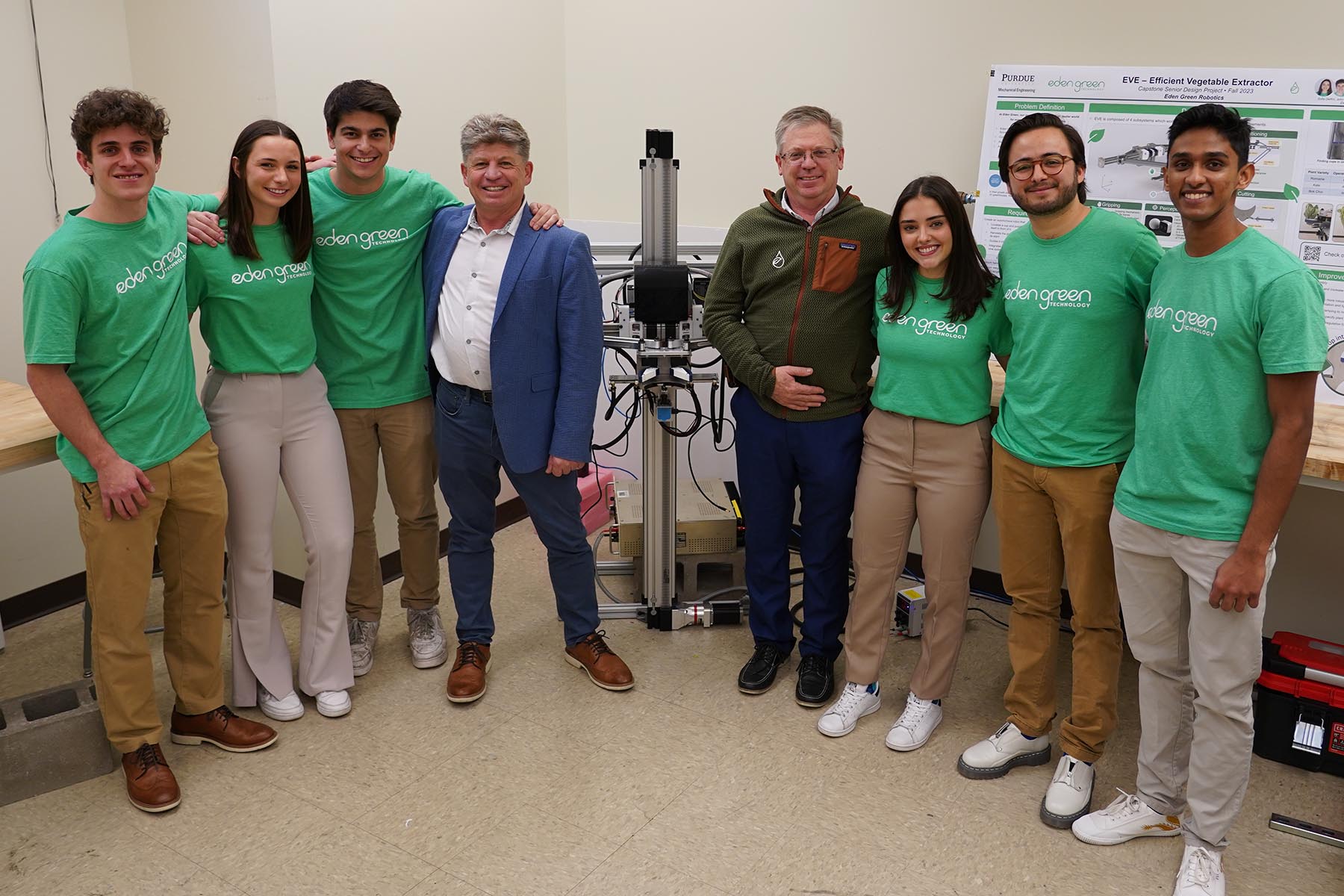

As part of their final undergraduate class, Purdue Mechanical Engineering students team up to design and build new prototype products in just 16 weeks, continually refining and improving them using the knowledge from all of their engineering courses. In 2007, these capstone design projects became part of a new event: the Thomas J. & Sandra H. Malott Innovation Awards. Tom Malott (BSME 1962) is the former president & CEO of Siemens Energy and Automation, and also served as an executive with Parker-Hannifin and the Ransburg Corporation. Purdue awarded Malott an honorary doctorate in 2002.

As part of the Malott Awards, students present their final prototypes to a panel of industry judges, who select award-winning teams based on innovation, engineering excellence, and manufacturability. Today, more than a hundred teams compete in the Malott Innovation Awards every year — so many that their project showcase now fills up the entire Purdue Armory. Some projects are so successful, students end up patenting them and putting them on the market.

Time for a Change

In 2012, the Mechanical Engineering building welcomed its first addition in 64 years: the Gatewood Wing. Named after lead donor Roger B. Gatewood (BSME 1968), the $34.5 million wing increased the size of the building by 57 percent (correctly predicting the explosive growth in Purdue ME’s student population).

In addition to looking to the future, the Gatewood Wing also maintains a foundational link to the past: the old Heavilon Hall mechanical clock. Jack Fessler, Mike Sherwood, and Galen King worked to refurbish the clock and its 11-foot pendulum, manufacturing new pieces and securing a modern clock face and hands. When the Gatewood Wing opened in 2012, the clock ticked successfully for the first time in more than half a century. The 200-pound counterweight must be cranked up every four days to keep accurate time using purely mechanical forces — just as it did for Purdue ME students a century ago.

Hammer Down

Another link to Purdue’s past is the hammer. The traditional tool of a Boilermaker, the hammer has since become a prominent symbol for the school of Mechanical Engineering. Each student learns how to use the machine shop by building their own keepsake hammer.

This reputation was cemented in 2020, when the COVID pandemic disrupted the world. Purdue ME offered students research opportunities and paid service projects to fill in the gap of canceled internships. One project involved redesigning the ME hammer; the new 100% aluminum hammer would become the cornerstone of a renewed manufacturing curriculum, leading students through the design process and putting the “maker” back into “Boilermaker.”

Famous Alumni

Purdue Mechanical Engineers can be found everywhere — from boardrooms to factory floors to laboratories, and even in space! Here are some ME grads who became notable in fields you might not expect:

- Ray Ewry (BSME 1897) became a legendary Olympic athlete. By some measures, he is the greatest jumper in Olympic history: he earned eight individual gold medals, a record that stood for more than 100 years.

- David Crosthwait (BSME 1918, MSME 1920) designed the heating system for New York’s Radio City Music Hall and Rockefeller Center.

- John Attala (MSME 1947, PhD 1949) helped to develop the MOSFET, which became the basis for all integrated circuits and semiconductors since. He also developed the PIN (personal identification number) for ATMs.

- Moira Gunn (PhD 1974) started working at NASA but pivoted to public relations, and has hosted the public radio program “Tech Nation” for more than three decades.

- Bob Peterson (MSME 1986) drew comic strips for the Exponent, and eventually joined Pixar as an award-winning animator, story artist, writer, and voice actor for “Dug" the Dog.

- Ukari Figgs (BSME 1999) was an NCAA Final Four champion and a WNBA champion, before joining Toyota as General Manager for Manufacturing Excellence.

Capital Investment

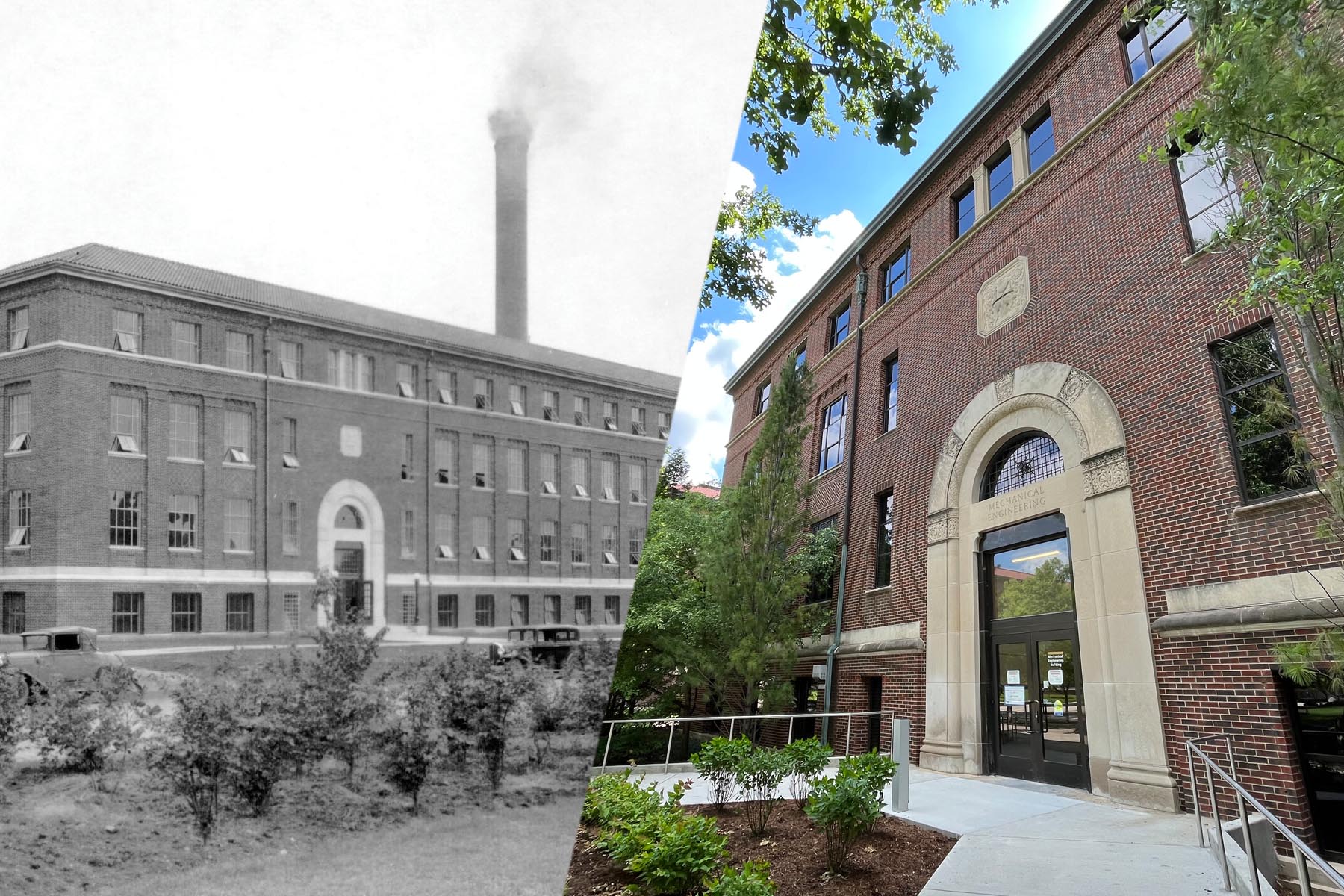

In 2025, two big projects changed the face of the School of Mechanical Engineering — renovating the original ME Building, and expanding programs in Indianapolis.

When IUPUI split in 2024, Purdue University gained nearly a thousand new mechanical engineering students in Indianapolis. This expansion created new collaborative opportunities, and also set records — Purdue now has the largest mechanical engineering program in the nation. Purdue also includes the only accredited motorsports engineering degree in the country, located just steps from the Indianapolis Motor Speedway.

In West Lafayette, the physical infrastructure struggled to keep up with skyrocketing enrollment. The Mechanical Engineering Building is actually a hodgepodge of five different buildings, built in different time periods from 1929 to 2012. As a result, the old building lacked modern elevators, restrooms, modern HVAC, and sufficient space for machine shops, instructional labs, and maker spaces. To achieve Purdue ME’s goal of 100% student participation in hands-on, multidisciplinary team projects, they pursued drastic changes in the building’s physical infrastructure.

From 2023 to 2025, the 1930s-era Mechanical Engineering Building was cleared to the studs, replacing outdated infrastructure with much needed modern restrooms, elevators, HVAC, and accessible entrances. New classrooms and labs relocated to the ground and 1st floors to improve student flow. Instructional labs were also rebuilt from the ground up, replacing temporary dividers with dedicated rooms to encourage the pinnacle of experiential learning.

“This has been a monumental effort,” said Eckhard Groll, the William E. and Florence E. Perry Head of Mechanical Engineering, and Reilly Distinguished Professor of Mechanical Engineering. “We wanted to make the building more student-friendly, more accessible, and more accommodating of the growth of students who want what Purdue has to offer.”

“I want to thank everyone involved who helped to make this happen,” Groll continued, “from the donors, to the administration, to the construction firms, to the very flexible faculty, staff, and students who had to relocate for two years. Without their support, we couldn’t make this happen. I firmly believe that the School of Mechanical Engineering is in the best place it has ever been!”

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374