Boiler Up: restoring an original 1915 Purdue steam engine

Growing up on a farm outside Logansport, Indiana, Bill was turning wrenches from an early age. “I was always the kid that was tearing things apart to see how they worked,” he says. “I also had an interest in antiques, since my parents collected antique tractors and engines.”

The decision to attend nearby Purdue University came easily – even if the classes didn’t. “It was very challenging,” he admits. “Many students come in to Purdue not quite knowing what they want to do, and I was no different. I chose mechanical engineering because I was mechanically inclined. But I had to work lots of late nights to pass those classes!”

He favored the kinematics classes, especially as taught by Farshid Sadeghi and Chuck Krousgrill. And he joined ASME’s Grand Prix team, which kept him turning wrenches on the weekends.

He also continued pursuing his love of antiques, attending shows and sales throughout Indiana. At one estate sale, he was looking through a barn full of rusted tractors and equipment, when he came across something interesting. “It wasn’t advertised as a steam engine, but I recognized it immediately,” he says. “It hadn’t been touched in decades. The owner mentioned that he thought it came from Purdue. I said, ‘I have to own that for sure!’”

When the steam engine came up for auction, Bill submitted the winning bid. “I was still a junior at Purdue when I bought it,” Bill remembers. “It wasn’t hugely expensive, but I did have to get a little bigger student loan that year!”

The engine had no documentation or provenance. He identified it as a Baker Uniflow model, patented in 1915 and manufactured in Swanton, Ohio. To confirm the Purdue connection, he looked up Purdue course catalogs from as early as 1920 listing a Baker Uniflow among the inventory of their Steam Engine Laboratory. Two other clues led Bill to believe that he had the genuine article. “I found a serial number, PU21970, stamped on the flywheel,” he says. “It also had brackets for specific scientific instruments, which wouldn’t be there if the engine was in a factory or a farm.”

Bill eventually had to hit the pause button on his steam research. After graduating from Purdue in 1990, he started working for a company in Elkhart, Indiana that designed automotive seats. His skills in designing mechanisms led him to the Detroit area, where he has spent the last two decades designing automotive seats, seat belts, airbags, and structural components. He currently is Lead Engineer for STRATTEC, designing automatic door closure actuators.

But in his spare time, he never stopped thinking about the Baker Uniflow, and its role in Purdue’s history.

Full steam ahead

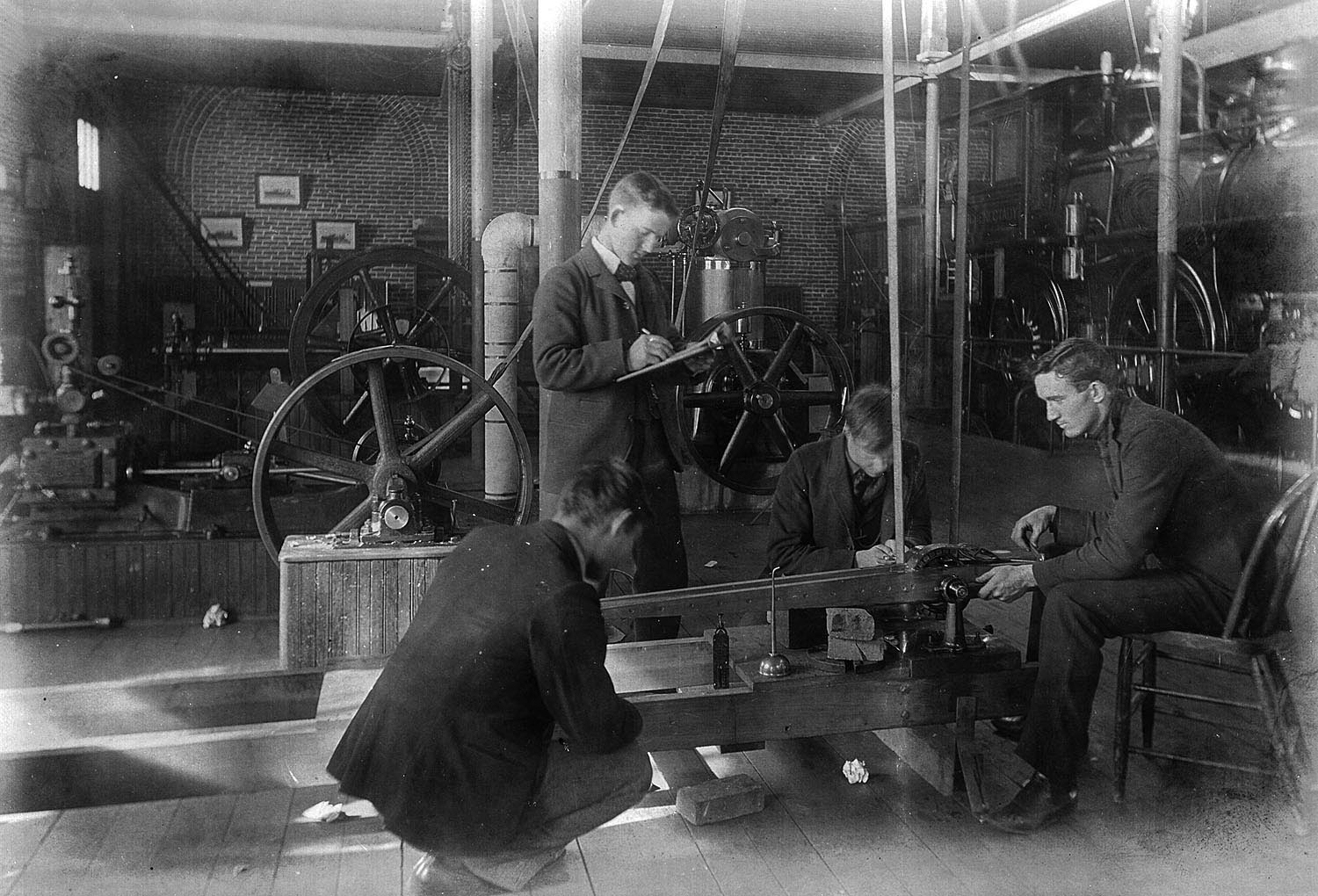

The history of Purdue University is inextricably linked with steam power. In September 1891, Purdue took the risk of spending $8,000 on a steam locomotive, Schenectady No. 1, for its engineering school. It became the first locomotive ever studied under laboratory conditions, and came to define the young university.

Steam power was the pinnacle of technology at that time, and Purdue had become its Silicon Valley. Railroad officials visited from around the world, flabbergasted to see the Schenectady chugging mightily in place up to 80 miles an hour on a dynamometer. Demonstration engines filled the original Heavilon Hall (predecessor to the Mechanical Engineering building), where researchers measured every aspect of their operation. Even football players were accused of recruiting “burly boiler makers” to their team – symbolism that Purdue embraces to this day.

However, internal combustion engines soon overtook steam engines in efficiency and power. By the 1930s, steam engineering research was in full decline. Purdue sold its final steam locomotive for scrap to support the war effort. Most other equipment was donated to museums, or discarded altogether.

Boiler Up

Which brings us back to Bill Champ’s garage, and the Baker Uniflow. It’s about the size of a compact car, and weighs just as much. Decades of sitting in a barn have given every component a thick patina of rust. Bill gives a tug to the massive flywheel, causing the single 6-inch-bore piston to slowly move back and forth. “This is probably the first time it’s operated in a hundred years!” he laughs.

Bill describes how this massive machine would have operated. Steam piped in from a generating plant would first pass through a governor, consisting of rotating iron spheres on spring steel. If at any time it spun too fast, the governor would close the main valve to stop the flow.

Then the steam would enter a valve next to the main piston, allowing steam to enter one part of the cylinder to move the piston, and then alternate to the other side to send the piston back. A mechanical oil pump kept the cylinder lubricated. The piston pumped 200 times a minute, generating up to 20 horsepower. Through a system of belts and pulleys connected to a flywheel, this could power an entire laboratory. In Bill’s setup, a thick cotton belt connects the engine to a vintage electrical dynamo, generating 3000 watts of electricity at 125 volts.

That’s the theory, at least. While Bill has dreams of restoring the engine to working condition, he admits there are years of work ahead of him to reach that goal. “The first step is to take everything apart and sandblast it,” he says. “Many parts need to be re-machined or replaced. And of course, I still need a boiler to supply a source of steam. I would love to someday put this on a trailer and take it to schools, to show students how our world was powered 100 years ago.”

To that end, Bill has also amassed a huge collection of scientific instruments and other paraphernalia that would have been used by Purdue researchers to study the engine’s operation. For example, one instrument records steam pressure by means of a paper and pencil. The steam pressure pushes the pencil up and down, while a string connected to the crankshaft rotates the drum of paper. The resulting graph can be analyzed by another analog instrument, a planimeter, to derive measurements of engine operation over time.

That’s just one of dozens of meters, instruments, and calibrating equipment that fill tables and shelves in Bill’s garage. He’s even amassed a complete set of steam whistles, from a tiny one-inch diameter tooter to an 8-inch diameter behemoth from a steamship, which you can hear from miles away. “I’m always on the lookout to collect steam components and artifacts,” he says, “especially textbooks that describe how they work, because nobody alive has operated these things!”

So why tackle this massive project? “It’s part of our history,” says Bill. “Purdue is known for researching and creating new technologies. But it all started with engines like this. We can’t let all that disappear. The locomotives are all gone, and this is likely the only Purdue steam engine that still exists. We can’t forget about these things, because they got us to where we are today.”

In the same way, the principles Bill first learned at Purdue still guide him in his career. “It’s my job to design new mechanisms, with motors, sensors, and actuators,” he says. “As a Purdue student, I first learned how all those mechanisms work. I also learned how to think, and how to apply what I learned to real-world applications. Hands-on learning, combined with classroom learning, makes you a good engineer.”

Writer: Jared Pike, jaredpike@purdue.edu, 765-496-0374