Purdue Engineering to expand national roadmap leadership through 2 NIST projects, benefiting pharmaceuticals, microelectronics

Already at the forefront in advanced manufacturing technology, Purdue Engineering will expand its impact by serving as a leader or key partner in two new national projects that will strengthen the pharmaceutical and microelectronics industries.

The College of Engineering will lead one of the four 2022 Advanced Manufacturing Technology Roadmap Program (MfgTech) projects launched by the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) in April, and will be a key partner in another such project.

The Purdue-related projects will bring industry, academic and NIST experts together to build technology roadmaps to address national priorities for vaccine manufacturing capabilities and microelectronics competitiveness. The roadmaps will be used to identify and rank research and development goals, define workforce needs, and initiate other steps toward speeding technology development and transfer and improving manufacturing capabilities.

The new NIST projects:

Purdue’s LyoHUB: To advance novel freeze-drying technologies and applications for emerging classes of therapeutics and vaccines

The Advanced Lyophilization Technology Hub (LyoHUB), a Purdue-led industry consortium, was established by NIST in 2014 to advance the science and technology of lyophilization, or freeze drying, focused on pharmaceutical manufacturing. LyoHUB broke new ground when it opened a technology demonstration facility in Purdue Discovery Park’s Birck Nanotechnology Center in 2016 and produced the first lyophilization roadmap in 2017. In addition, LyoHUB is developing influential best practices and collaborated with the ASTM on creation of the first technical consensus standard for lyophilization in 2021.

“The new project will build on LyoHUB’s successes and position the consortium for ongoing impact,” said Alina Alexeenko, founding co-director of LyoHUB, and professor of aeronautics and astronautics and chemical engineering. “In this next phase, we will expand our roadmap to include novel technologies and applications for emerging classes of therapeutics and vaccines, allowing the pharmaceutical industry to deploy effective medicines and vaccines more efficiently and rapidly.”

Lyophilization is used in manufacturing almost half of new biopharmaceuticals. Providing a sterile, vacuum environment to remove water from drug products after they are frozen, it converts the frozen moisture to a vapor, eliminating the liquid phase. This process increases the stability and shelf life of medications and eases their long-term storage and shipping.

“However, the process is highly complex and not time- or energy-efficient, with few fundamental changes since it was introduced for medical applications in the 1940s,” Alexeenko said. “We’re working to improve processes, products and equipment, for example, by using advanced computational simulations, analytical methods and new technologies such as radio frequency (RF)-assisted heating. Moving from batch processing to continuous freeze drying is one goal. Also, in the new project, we’ll be exploring other kinds of drying technologies to save time and money while preserving product integrity.”

Alexeenko leads LyoHUB with co-founder and co-director Elizabeth Topp, a Purdue professor of industrial and physical pharmacy.

In addition to collaborating with prominent industry members, LyoHUB roadmap development will include researchers with Purdue’s Department of Industrial and Physical Pharmacy, University of Connecticut, and University of Minnesota.

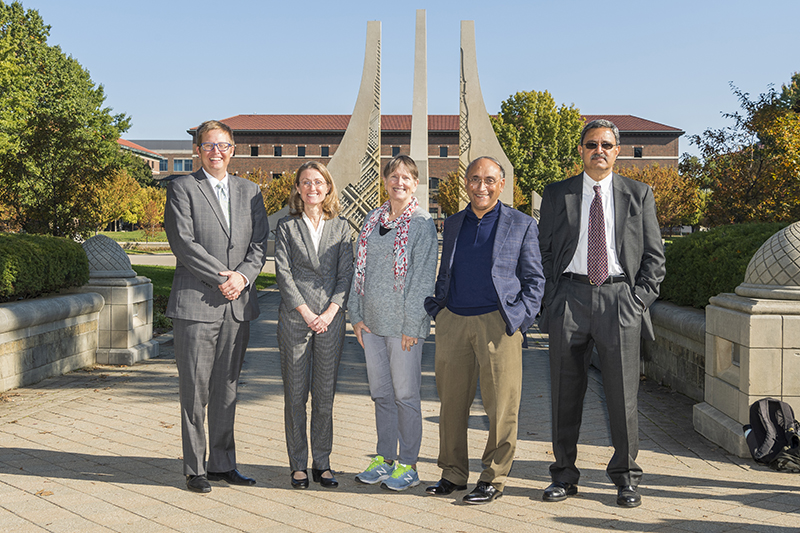

Semiconductor Research Corporation (SRC): To define the future goals of the microelectronics and advanced packaging technology (MAPT) industry

Purdue Engineering will play a major role in this NIST Roadmap project, whose impact is expected to be extensive. Guided by national and University priorities of bolstering U.S. competitiveness in microelectronics, Purdue is a leading partner of SRC, an American microelectronics technology research consortium.

As a national leader in microelectronics devices and advanced packaging research, Purdue will leverage its comprehensive strengths and successes to drive advanced technologies to help the U.S. regain its competitive advantage. Indicating national urgency, President Biden issued an executive order on strengthening America’s supply chains, including those for semiconductor manufacturing and advanced packaging, and the Senate is considering the $52 billion USICA/CHIPS Act.

“Our College of Engineering is ideally suited to help revitalize the American microelectronics industry,” said Carol Handwerker, the Reinhardt Schuhmann Jr. Professor of Materials Engineering, Professor of Environmental and Ecological Engineering, and an international authority on microelectronics. “We are among the world’s experts in advanced packaging and heterogenous integration, which are key to faster, smaller, higher-performance semiconductors. We also have deep experience in bringing together academic and industry partners to address significant needs.”

Handwerker said Purdue’s work to date and the NIST project aim to solve a growing dilemma: While microchips have gained power, the fabrication technologies that doubled performance without increased cost are reaching their limits. Microchips have become so large and complex that they are difficult and expensive to produce, and more vulnerable to defects. Figuring out how to connect them is another issue.

“Advanced packaging and heterogenous integration can enable smaller, separately fabricated microchips to be packaged closer together with high performance at low cost," Handwerker said. “Innovations in design, materials and processing are needed. The NIST project will enable us to scale up our work in developing new materials, new measurement technologies and interconnection technologies for systems with ever-higher performance and functionality.”

“The roadmapping will be critical in identifying the research, workforce, supply chain, prototyping, and manufacturing innovations needed to build back the national advanced packaging ecosystem that has been lost over the past 25 years,” said Ganesh Subbarayan, Purdue professor of mechanical engineering. He is co-director of the Purdue-led Center for Heterogenous Integration Research in Packaging (CHIRP) – the only SRC-funded university center dedicated exclusively to advanced packaging research and one of three SRC centers Purdue leads.

Subbarayan added, “The resurgence of the microelectronics packaging industry is strategically important to the nation in commercial and defense products because, increasingly, as we reach limits of Moore’s law, packaging is the differentiator for electronic products in meeting industry’s energy utilization, performance, size, and cost targets.”

Developing chips with ever-greater functionality for cell phones, computers, infrastructure, automobiles, defense, and space electronics will require a diverse, inclusive, highly trained workforce pursuing microelectronics careers and creating ground-breaking solutions. To that end, Handwerker and Subbarayan co-lead the heterogeneous integration and advanced packaging program of the Purdue-based U.S. Department of Defense’s Scalable Asymmetric Lifecycle Engagement (SCALE) workforce development initiative, which works in tandem with the Purdue-led Center for Secure Microelectronics Ecosystem (CSME).

In the SRC-led NIST project, Purdue is collaborating with companies including AMD, IBM, Intel and Texas Instruments; academic partners Binghamton University, Georgia Tech, Morgan State University and Hampton University; and two key supply chain partners: IPC, a standards association for the electronics manufacturing industry, and iNEMI, an electronics manufacturing industry research and development consortium.