Purdue Engineering emerges as the national leader in degrees awarded and market demand

Purdue Engineering has emerged as the national leader among engineering colleges by two key measures: degrees awarded and market demand.

July 28, 2025

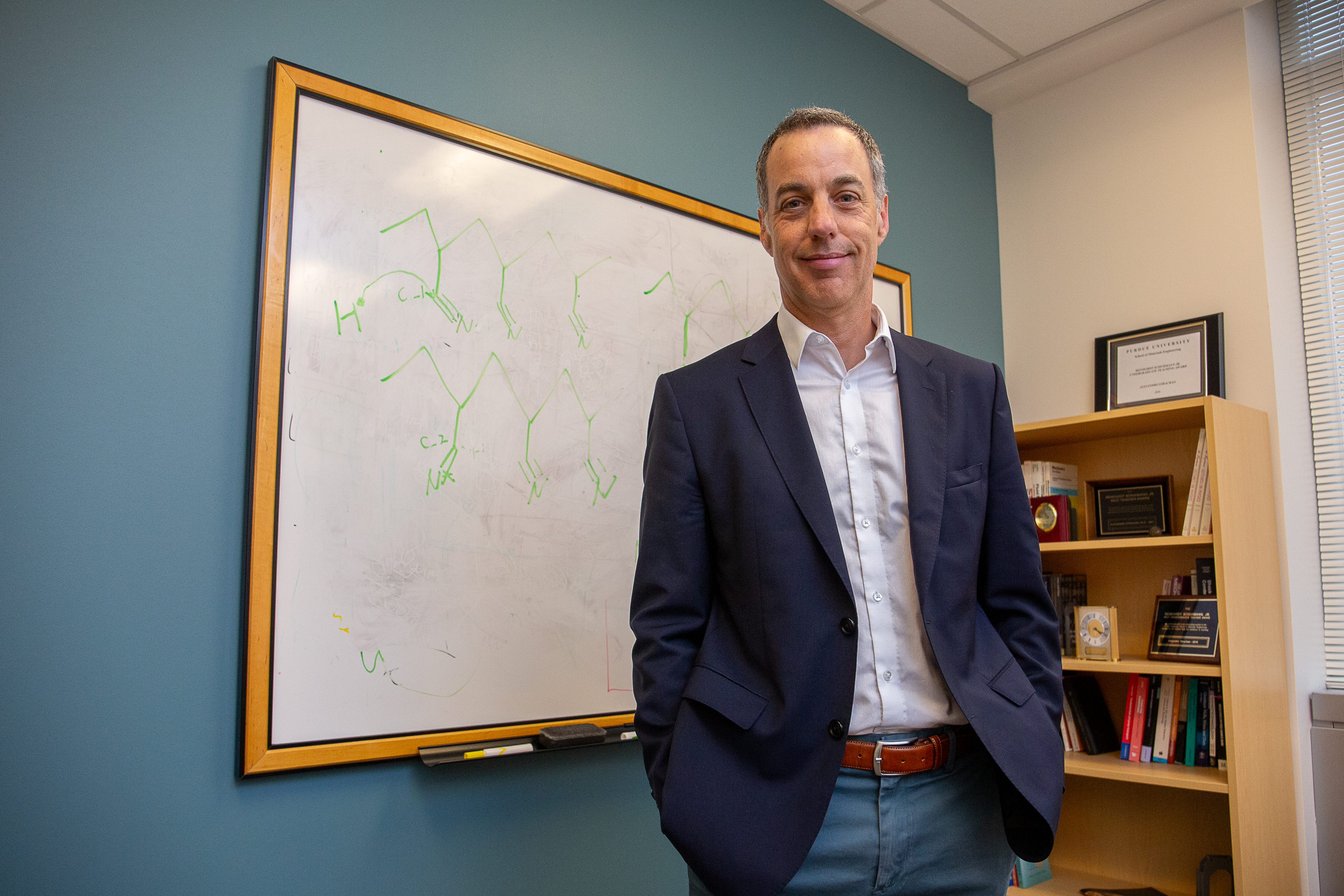

ECE's Michael Zoltowski earns prestigious IEEE Life Fellow distinction

Michael D. Zoltowski, the Thomas J. and Wendy Engibous Professor in Purdue University's Elmore Family School of Electrical and Computer Engineering, has been elevated to IEEE Life Fellow, one of the most prestigious honors bestowed by the Institute of Electrical and Electronics Engineers (IEEE).

December 12, 2025

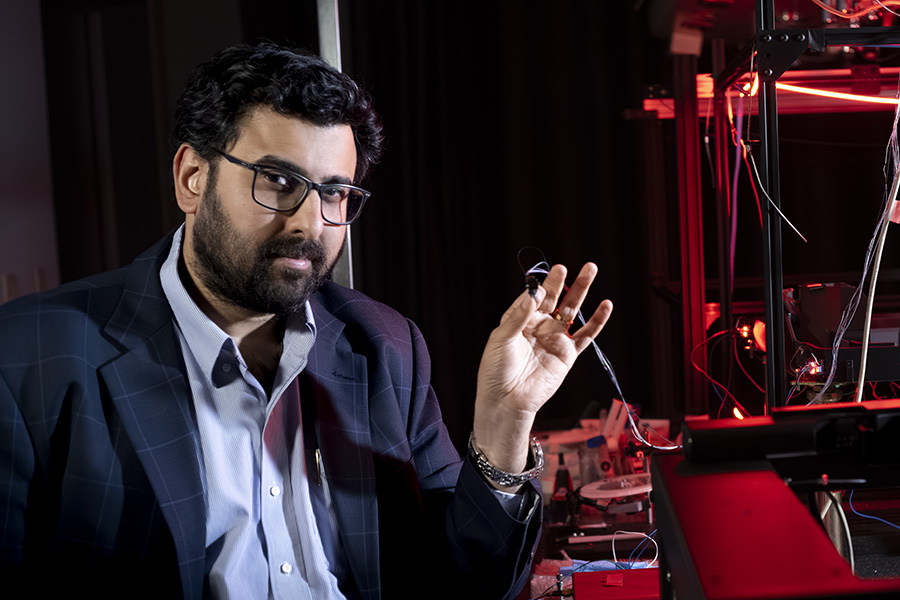

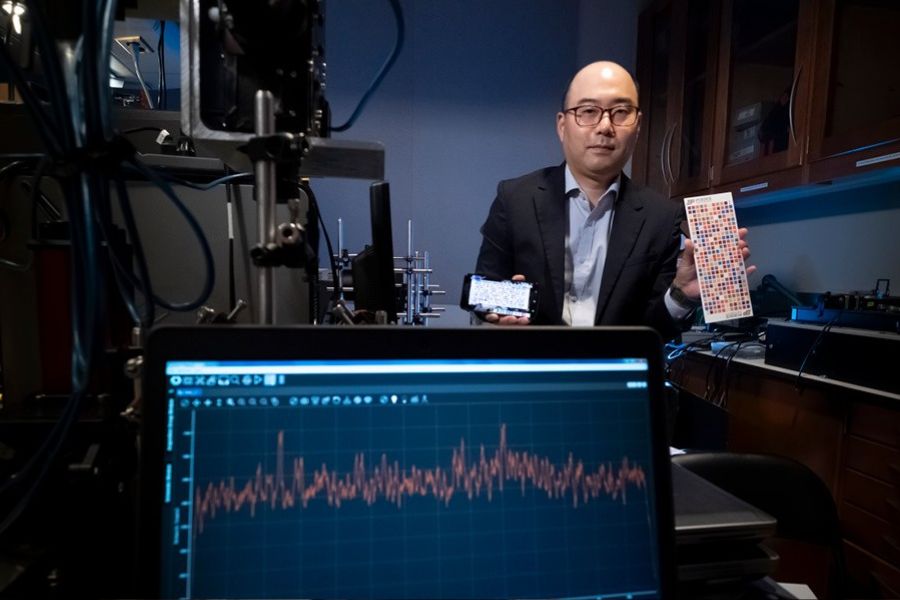

Four Purdue Engineering faculty receive prestigious 2026 IEEE fellow designation

The IEEE fellow distinction -- awarded annually by IEEE, the world's largest technical professional organization -- is reserved for a select group of members whose exceptional contributions to engineering, science or technology have significantly advanced their fields.

December 17, 2025

Three Purdue Engineering faculty named to 2025 Highly Cited Researchers list

Three Purdue Engineering faculty have been named to Clarivate's 2025 Highly Cited Researchers list, a prestigious recognition that places them among the world's most influential scientific minds.

December 23, 2025