An introduction to this issue of FRONTIERS magazine by Dean Arvind Raman.

10 minutes to read

This issue of FRONTIERS highlights many examples of Purdue Engineering’s continuing progress toward becoming one of the most consequential U.S. engineering colleges. We share information on major research centers, groundbreaking partnerships, new computing synergies, latest semiconductor milestones, impactful research, new patents and innovations, and recognition.

For example, you’ll find stories on:

The Hypersonics and Applied Research Facility (HARF) – a $41-million, 65,000-square-foot building dedicated to enhancing Purdue’s world-leading capabilities in hypersonics evaluation and testing. HARF houses the only Mach 8 quiet wind tunnel in the world and the hypersonic pulse (HYPULSE) reflected shock/expansion tunnel.

A $50-million, five-year extension of Purdue’s research agreement with Eli Lilly – part of a broader pact including pharmaceutical manufacturing scholarships. The new expansion involves collaborative research focused on genetic medicine, as well as drug delivery methods for better patient outcomes and experiences.

The eXcellence in Manufacturing and Operations (XMO) initiative – an academic-government-industry partnership to drive Purdue efforts to spearhead a U.S. resurgence at the intersection of physical, digital and sustainable manufacturing. This initiative transcends Engineering to solve complex problems in such areas as microelectronics manufacturing, food equity, Space 2.0 for commerce and security, the greater good, and sustainability.

Purdue University in Indianapolis – Purdue’s first comprehensive urban campus, which will provide unique opportunities to students, faculty and partners in Indianapolis and West Lafayette. The new university, to begin operating July 1, 2024, will assume responsibility for existing engineering, computer science and technology programs at IUPUI and confer Purdue West Lafayette degrees, as Purdue gains ability to introduce programs and grow enrollments in Indianapolis.

Our increasing primacy in semiconductors – demonstrated by a $49 million Purdue investment in the Birck Nanotechnology Center, including its semiconductor cleanroom, and new or renewed international research and workforce development partnerships. Among partners are Taiwan Semiconductor Manufacturing Co. (TSMC), Taiwan’s National Yang Ming Chiao Tung University (NYCU), National Chengchi University (NCCU), and European-based innovation hub imec. You’ll also learn about engagement with leading tech companies and government officials from India, Europe, Japan and the U.S. to advance R&D collaborations.

Additional topics in this issue include a new $20 million center for transportation cybersecurity; the world’s whitest paint, which can reduce air-conditioning needs; and a $70 million program that applies a “LASER” focus to humanitarian supply chains.

John A. Edwardson Dean of the College of Engineering,

Robert V. Adams Professor in Mechanical Engineering,

Professor of Materials Engineering (by Courtesy)

Purdue University

College of Engineering Administration

- Arvind Raman | Dean of Engineering

- Alina Alexeenko | Senior Associate Dean for Undergraduate Education and Academic Programs in Indianapolis

- Lisa Arafune | Chief of Staff

- Weinong Wayne Chen | Associate Dean for Research and Innovation

- Tamara Kinzer-Ursem | Associate Dean for Graduate and Professional Education

- Luna Lu | Associate Dean of the Faculty

- James Krogmeier | Associate Dean for Facilities and Operations

- Beth Holloway | Senior Assistant Dean for Student Access and Success

- George Chiu | Assistant Dean of Global Engineering Programs and Partnerships

- William Sondgerath | Assistant Dean for Staff and Director of Administration

- Jason Dietz | Senior Director of Financial Affairs

- Brittany Vestal | Director of Financial Affairs

- Korina Wilbert | Deputy Chief of Staff

- Jill Vigar | Dean's Office, Executive Assistant and Manager

Production

- Christine Babick | Director of Communications

- Della Pacheco | Project Manager

- Laura Abbott, Stacy Cardie | Editors

- Kate Theobald | Senior Design Manager

- Devynn Leatherman-May | Lead Designer

- Design Team: Eric Smoldt, Ashton Helmke, Kyle Redmond

- Photographers: Pooja Chaudhary, Kelsey Lefever, Charles Jischke, Rebecca Robiņos, John Underwood, Vincent Walter, Yash Trivedi, and Robb Cohen

School and Division Heads

- William Crossley | Aeronautics and Astronautics

- Nathan Mosier | Agricultural and Biological Engineering

- Nan Kong | Biomedical Engineering (interim)

- Sangtae Kim | Chemical Engineering

- Rao Govindaraju | Civil Engineering

- Makarand Hastak | Construction Engineering and Management

- Milind Kulkarni | Electrical and Computer Engineering (interim)

- Edward Berger | Engineering Education (interim)

- John Sutherland | Environmental and Ecological Engineering

- Young-Jun Son | Industrial Engineering

- David Bahr | Materials Engineering

- Eckhard Groll | Mechanical Engineering

- Seungjin Kim | Nuclear Engineering

Applied research institute opens $41M hypersonics facility / Purdue, Eli Lilly sign new $50M research program / $20M national research center on cybersecurity established (Photo Credit: Purdue University)

10 minutes to read

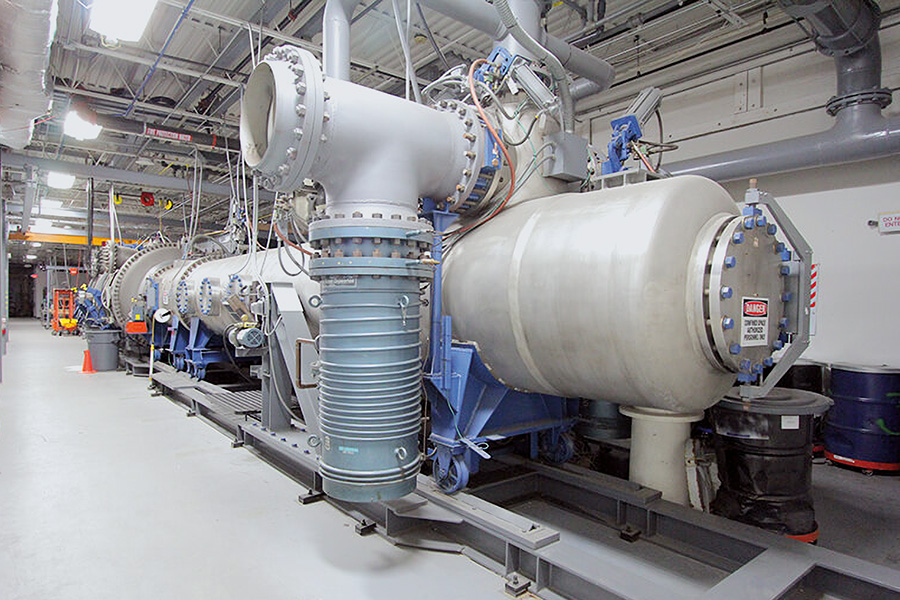

Banner image: Prior to the launch of PARI, Aerospace Sciences Laboratory at Purdue University included the Boeing/ AFOSR Mach-6 Quiet Tunnel. Joseph Jewell, the John Bogdanoff Associate Professor of Aeronautics and Astronautics, led a tour of that tunnel during the Hypersonics 2.0 Summit.

Purdue Applied Research Institute opens $41M hypersonics and applied research facility

The Purdue Applied Research Institute (PARI), the applied research arm of Purdue University, officially opened a new facility in June dedicated to enhancing Purdue’s world-leading capabilities in hypersonics evaluation and testing.

Leaders from Purdue, the federal government and industry joined PARI leadership and staff in celebrating the opening of the Hypersonics and Applied Research Facility (HARF), a $41-million, 65,000-square-foot building that is home to two cutting-edge wind tunnels: the only Mach 8 quiet wind tunnel in the world and the hypersonic pulse (HYPULSE) reflected shock/expansion tunnel. HARF also houses the Hypersonics Advanced Manufacturing Technology Center (HAMTC), a single location for industry partners to work on materials and manufacturing innovations and provide access to testing capabilities.

The tunnels recreate different scenarios, such as spacecraft re-entry or missile flight through the atmosphere, as well as replicating unique engine conditions for extremely high-speed propulsion. The Mach 8 quiet wind tunnel and the HYPULSE tunnel offer controlled environments to research several facets of high-speed flight. The wind tunnel more closely simulates flight and provides more accurate data than conventional hypersonic wind tunnels.

The HYPULSE tunnel uses a shock wave of high-temperature air to recreate specific hypersonic flight conditions. It allows flight simulations at speeds ranging from Mach 5 to as high as Mach 40. Purdue will be only the second U.S. university to offer HYPULSE test capabilities.

At HAMTC, researchers can collaborate with industry partners to develop materials and manufacturing innovations. HAMTC is the only vertically integrated prototyping center in the nation that enables the design, manufacturing, joining and testing of hypersonic components and subsystems in one location, speeding time from concept to full-fledged product.

Purdue, Eli Lilly sign a new $50M phase 2 research program

This collaboration extends the work for another five years, with a research focus on genetic medicine, intrathecal delivery and nanoparticle drug delivery

Intrathecal delivery entails the injection of drugs into the fluid that fills the space between thin layers of tissue that cover the brain and spinal cord. Physicians use the route of administration to treat cancers that have spread, or may spread, to the cerebrospinal fluid.

Lilly entered into a five-year, $52-million research collaboration with the university in 2017. That agreement positioned the drugmaker to tap into Purdue’s expertise to improve delivery of injectable medicines. Lilly identified the university as a potential enabler of its goals of reducing pain, decreasing the number of injections, and enabling better patient compliance and overall health.

The $50 million commitment to the Purdue research collaboration is part of a broader $92.5 million pact with the university that includes pharmaceutical manufacturing scholarships.

“The number of people who may benefit from our innovative medicines continues to increase, we are investing to advance critical research and build a more diverse pipeline of talent in Indiana,” said David A. Ricks, Lilly’s chair and CEO and Purdue Industrial Management alum.

Purdue and Lilly have a historic relationship, dating back to the organizations’ founding years. Those collaborative research efforts have helped advance understanding of the physiology of drug delivery and develop technologies to improve delivery of pharmaceuticals for better patient outcomes and experiences.

Purdue researchers include Pavlos Vlachos, the St. Vincent Health Professor of Healthcare Engineering and director of the Regenstrief Center for Healthcare Engineering in the School of Mechanical Engineering; Yoon Yeo, associate department head of industrial and physical pharmacy and the Lillian Barboul Thomas Professor of Industrial and Physical Pharmacy and Biomedical Engineering; and Luis Solario, associate professor of biomedical engineering.

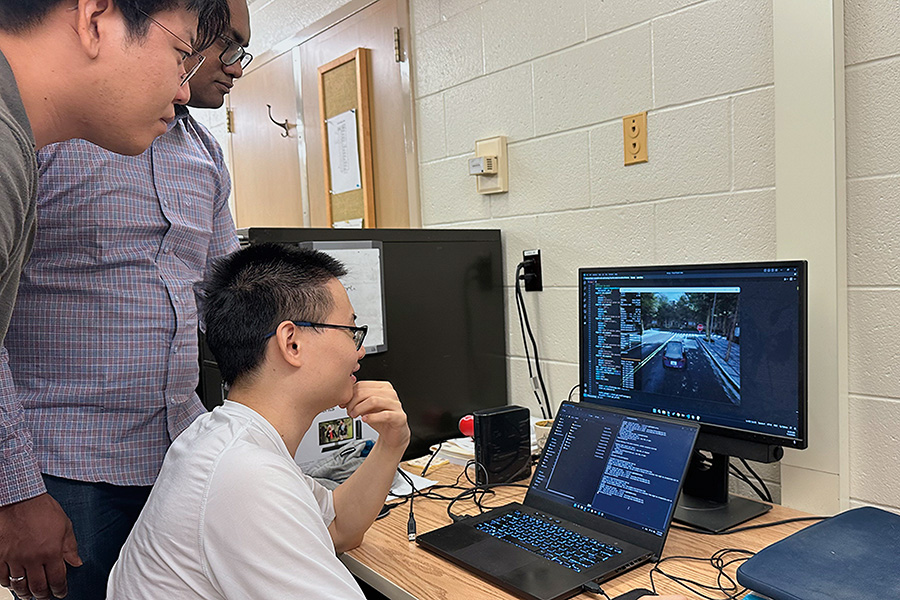

Purdue is part of $20M national research center aimed at hardening transportation systems against cyberattacks

Purdue was selected as a major partner on a new University Transportation Center (UTC) focused on cybersecurity and funded by the USDOT

The new center for Transportation Cybersecurity and Resiliency (TraCR), led by Clemson University, is the first national security center funded by the U.S. Department of Transportation (USDOT). TraCR will receive $20 million from the DOT over a five-year grant period.

UTCs will help the next generation of transportation professionals make roads, bridges, rail, shipping and airspace safer, more innovative and more efficient. The centers — 34 of which received grant awards up to $435 million in February — advance transportation expertise and technology in the varied disciplines that comprise the field of transportation through education, research and technology transfer activities, according to the DOT release.

Satish Ukkusuri, the Reilly Professor of Civil Engineering, will lead Purdue’s center. Other members of the Purdue team include Dongyan Xu, the Samuel D. Conte Professor of Computer Science and director of the Center for Education and Research in Information Assurance and Security (CERIAS); Berkay Celik, assistant professor of computer science; Yiheng Feng, assistant professor of civil engineering; Aniket Kate, associate professor of computer science; and Vaneet Aggarwal, professor of industrial engineering.

“With increasing connectivity, electrification and autonomy of transportation systems, the TraCR center will lead to world-changing research in transportation cybersecurity in connected and autonomous transportation systems, electric vehicles, and supply chains, and will develop algorithms, testing and tools that will defend the next-generation transportation systems,” Ukkusuri said. “The research will develop not only mitigation methods but also anticipatory techniques advancing transportation cybersecurity. The center builds on the significant strengths of the Purdue transportation research, education and workforce development over the years.”

TraCR will continuously monitor and address the vulnerabilities of cybersecurity associated with transportation cyber-physical-social systems (TCPSS). These systems use computations and communication embedded in and interacting with physical processes to add new capabilities to transportation systems.

Researchers will work on identifying challenges and threats across transportation modes, geographies, and applications, as well as pioneering advanced cybersecurity strategies and solutions for multimodal transportation.

The researchers expect to develop software and hardware that will function as the crucial backbone for preventing and mitigating potential cyberattacks on transportation systems, such as data falsification and Global Positioning System (GPS) spoofing attacks. Wirelessly connecting vehicles to each other (vehicle-to-vehicle) and to the roadway infrastructure (vehicle-to-infrastructure) holds the promise of reducing gridlock, crashes, fuel use, emissions, and social inequities. However, it also introduces vulnerabilities that need to be mitigated and anticipated. With every vehicle and piece of infrastructure that connects to the internet, there is opportunity to steal data, invade privacy, demand a ransom, generate misinformation, or even shut down a whole system.

One of Purdue’s key contributions will be to ascertain the network-level impact of cyberattacks on connected and autonomous vehicles, electric vehicles, and ride-hailing systems. The research team will develop quantum computing-based algorithms to anticipate and mitigate vulnerabilities in the transportation system. Testing will take place in real-world scenarios and on simulation platforms, both of which will be designed and developed by Purdue researchers.

Additional partnering institutions are Benedict College, Florida International University, Morgan State University, South Carolina State University, the University of Alabama, the University of California, Santa Cruz and the University of Texas at Dallas.

(Photo credit: Purdue University | Charles Jischke)

The $41-million, 65,000-square-foot building that is home to two cutting-edge wind tunnels: the only Mach 8 quiet wind tunnel in the world and the hypersonic pulse (HYPULSE) reflected shock/expansion tunnel.

(Photo credit: Northrop Grumman)

(Photo credit: Purdue Research Foundation)

(Photo credit: Purdue University)

(Photo credit: Purdue University)

(Illustration credit: Purdue University | Kyle Redmond)

Excellence in Manufacturing and Operations (XMO) Initiative Meets the Moment (Photo credit: Purdue University)

10 minutes to read

Banner image: XMO PEI co-chair, Stephan Biller speaking with XMO PEI co-chair, Ajay Malshe in preparation of the multidisciplinary scope and lab location for this new XMO initiative.

As the U.S. experiences a resurgence of manufacturing and operations, Purdue University is providing a big lead

Purdue’s efforts in vital fields such as semiconductors, aerospace, defense, biomanufacturing for agriculture, and transportation figure prominently in bringing jobs and needed technology back to America and in defining the future through excellence in manufacturing and operations. Purdue College of Engineering and its cross-Purdue partners already are leaders in driving this resurgence of American manufacturing. The eXcellence in manufacturing and operations (XMO) Purdue Engineering Initiative (PEI) will tap Purdue’s domain excellence to build a community of faculty, students and industries at today’s intersection of physical, digital and sustainable manufacturing. Manufacturing talent and workforce creation will be one of the strong components of the new PEI, enhancing training of the new workforce and empowering existing workers through retraining in the ecosystem of small, midsize and large companies that constitute Purdue’s industrial base.

Two faculty members who are globally recognized and commended for their research, teaching and private-sector innovations and entrepreneurship in advanced manufacturing and operations will co-chair the XMO PEI: Ajay P. Malshe, the R. Eugene and Susie E. Goodson Distinguished Professor of Mechanical Engineering, and Stephan Biller, the Harold T. Amrine Distinguished Professor in the School of Industrial Engineering and the Mitchell E. Daniels, Jr. School of Business. Malshe has gained a national and international reputation in academia, entrepreneurship and industries for advanced manufacturing, bio-inspired designing, functional multi-materials, and system integration and productization. Over the decades, application areas of his interest and contributions have included heterogeneous microelectronics for highdensity systems; nanomanufacturing for extreme machines; in-space servicing, assembly and manufacturing (ISAM) at the point of need; and biomanufacturing for future foods and farms for equity.

Biller’s research encompasses such subjects as smart manufacturing, digital twin, supply chain management, analytics, AI and cloud. He leverages his highly credentialed research, as well as extensive industry experience at IBM, GE and GM.

The multidisciplinary scope of these co-chairs’ research and other accomplishments mirrors the confluence of disciplines that governs advanced manufacturing and operations today as it spans physical processes, digital control, systems optimization and sustainable production.

“For the first time, we will expand the scope of a PEI across campus to the Mitchell E. Daniels, Jr. School of Business, the College of Agriculture, the College of Science and the Purdue Polytechnic Institute,” Biller said. “This will foster university-wide collaboration in the modern triad of digital, physical and sustainable manufacturing and operations, to boost U.S. efforts in reshoring, retooling and retraining the workforce in critical industrial sectors,”

As a land-grant university since its founding in 1869, Purdue always has featured a hands-on mandate to educate its engineering students for practical pursuits. Purdue’s Boilermakers nickname stems from the workers who built and maintained steam locomotives. "As ‘makers,’ Purdue people have manufacturing in their DNA,” Malshe said. “At this time, there is a national calling for manufacturing competitiveness,” said Malshe. “Our new PEI is an important Purdue instrument that will converge multiple disciplines, beyond Engineering, in order to solve complex problems — in areas from microelectronics manufacturing to food equity, to Space 2.0 for commerce and security — to provide digital smartness to manufacturing businesses across the United States. The XMO PEI will be keen on workforce creation, solving problems for the greater good and sustainability.”

Read the full-length story on XMO's website.

Stephan Biller, XMO PEI co-chair, Harold T. Amrine Distinguished Professor in the School of Industrial Engineering and the Mitchell E. Daniels, Jr. School of Business

Ajay P. Malshe, XMO PEI co-chair, R. Eugene and Susie E. Goodson Distinguished Professor of Mechanical Engineering

(Photo credit: Purdue University)

Launching Purdue's First Comprehensive Urban Campus (Photo credit: Purdue University | Rebecca Robiņos)

10 minutes to read

Banner image: Indiana University President Pamela Whitten and Purdue University President Mung Chiang (arms raised) celebrate the signing of agreements to dissolve IUPUI and establish separate university campuses in Indianapolis, beginning in July 2024.

Purdue University in Indianapolis brings unique opportunities to students, faculty and partners in both Indianapolis and West Lafayette

The new Purdue University in Indianapolis will assume responsibility for the existing engineering, computer science and technology programs at IUPUI and confer Purdue West Lafayette degrees. Purdue will also be able to introduce programs and grow enrollments in other colleges and departments in Indianapolis, such as the Mitchell E. Daniels, Jr. School of Business and colleges of Pharmacy, Health and Human Sciences, Science, and Agriculture.

Purdue anticipates substantially increasing today’s Indianapolis enrollment with plans for a 28-acre campus footprint stretching beyond the existing IUPUI engineering and technology buildings, which Purdue students will continue to use. Purdue received $60 million from the Indiana General Assembly to fund the first academic and student success building on the newly available land, and working groups are targeting additional building projects, including a possible new residence hall. Purdue University in Indianapolis students and faculty will continue to have access to all campus and academic facilities for the foreseeable future. Purdue is also exploring additional locations throughout the city of Indianapolis for expansion of academic and research programs.

To contribute to the civic life of the city and community and recognizing the historical significance of the area surrounding Indiana Avenue, Purdue has pledged support to the Indiana Avenue Certified Strategic Plan, which will inform the development of the surrounding neighborhoods, including the Purdue University in Indianapolis campus. Purdue University is also exploring additional physical facilities throughout Indianapolis.

Since Purdue University in Indianapolis is not a regional university, there is no chancellor. David Umulis, the Dane A. Miller Head and Professor of Biomedical Engineering, will serve as the chief academic officer for Purdue University in Indianapolis in his current role as senior vice provost, reporting to Provost Patrick Wolfe of Purdue University. Dan Hasler, who formerly served as secretary of commerce for the state of Indiana, will serve as chief operating officer for Purdue University in Indianapolis, reporting to Purdue President Mung Chiang.

Full-length story can be found on the Purdue news website.

"Starting today, new opportunities for Purdue University in Indianapolis are limitless."

Purdue President Mung Chiang

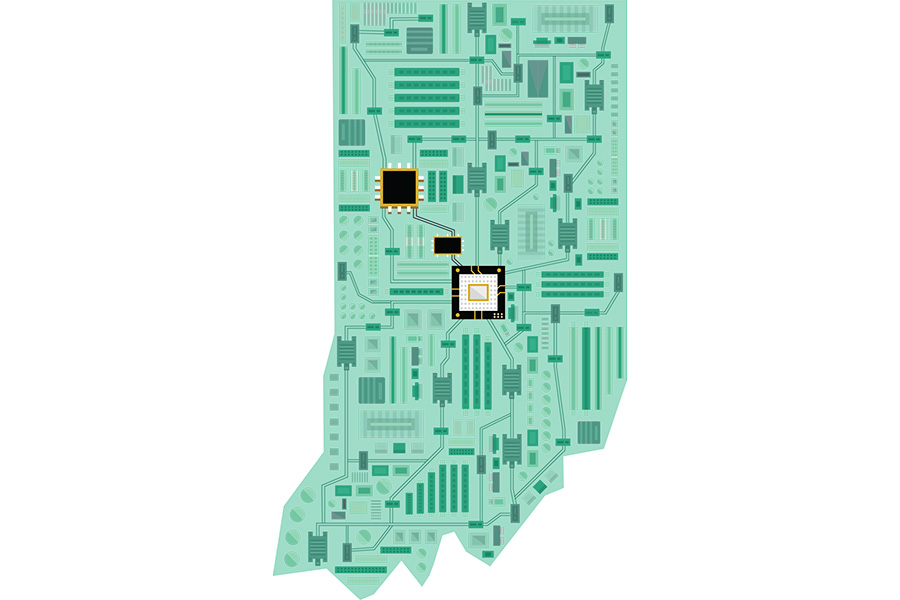

Forming America's Hard Tech Corridor in Indiana

10 minutes to read

The new Purdue University in Indianapolis will also serve as one bookend for 65-mile-long Hard Tech Corridor in Indiana

This corridor will be stretching from downtown Indianapolis, through the LEAP Innovation District in Lebanon with new sites from companies such as Eli Lilly and Company, all the way to Discovery Park District at Purdue in West Lafayette.

Purdue will invest in making the Hard Tech Corridor the most consequential engine of economic growth and brain gain in the Midwest as it continues to generate workforce, jobs and innovation together with partners.

After the IUPUI transition is completed, Purdue University will have continued collaboration with Indiana University, where each university’s strengths will enhance funding opportunities for joint research initiatives in Indianapolis, including creation of a joint institute for engineering in medicine between the Purdue University Weldon School of Biomedical Engineering and the Indiana University School of Medicine. This new institute will develop new life-enhancing therapies and technologies while simultaneously creating a highly sought-after pool of professionals whose unique research and training will create startups and attract new companies to the Indianapolis and central Indiana region.

Faculty, staff and students will also be able to take full advantage of new programs developed in Indianapolis integrated with departments pursuing advancements in cybersecurity, autonomy, advanced manufacturing, microelectronics, AI, business analytics, biomedical engineering, sports technology, hospitality and tourism management, and pharmaceutical discovery and manufacturing, to list a few.

Full-length story can be found on the Purdue news website.

Looking at the Numbers:

- 28-Acre Campus

- $60 Million in Funding

- 65-Mile-Long Corridor

Looking at the Goals:

- Most Consequential Engine of Economic Growth and Brain Gain in the Midwest

Computing synergies across science and engineering / Purdue launches nation's first institute for physical AI (IPAI) (Photo credit: Purdue University)

10 minutes to read

Banner image: The Scifres Nanofabrication Laboratory at Birck Nanotechnology Center is a 25,000-square-foot cleanroom with bays operating at ISO 3/4/5 (Class 1/10/100). The three-level structure consists of a full subfab, the clean room level, and an air-handling level above the cleanroom.

Computing synergies across science and engineering; Purdue invests in computing to meet student need

Advancing Purdue’s national leadership: Phase 1 of semiconductor facilities moving forward

As part of Purdue Computes, a three-pronged strategic initiative launched in April to further scale Purdue’s research and educational excellence in the future of computing, and recognizing that computing takes place in chips, Purdue announced the investment of Phase 1: a $49 million in semiconductor cleanroom upgrade and a planned Phase 2: another $51 million to help create an open innovation ecosystem1.

“Birck Nanotechnology Center has for decades been a critical home for discovery and technology development, both for Purdue researchers and those from industry and other universities who use our facilities,” says Zhihong Chen, the Mary Jo and Robert L. Kirk Director of the Birck Nanotechnology Center. “This investment will ensure that we maintain our state-of-the-art facilities, reclaim more space, and establish new capabilities for semiconductor R&D.”

Upgrades will include procurement of specialized equipment for device fabrication and characterization, and effort to increase capacity in the 25,000-square-foot Scifres Nanofabrication Laboratory cleanroom, one of the largest academic cleanrooms in the nation. It will include a dedicated training bay for use in preparing those enrolled in the university’s Semiconductor Degrees Program, such as Purdue undergrads, Ivy Tech students, and engineers in the field.

The upgrades will also create dedicated cleanroom and lab space for advanced packaging research — innovations in design, materials and processing that are needed to integrate chiplets with different functionalities — and shared quantum transport and characterization facilities, which are important to future electronic and quantum information science applications. Work will begin immediately and is expected to be completed in August 2024. The installation of new equipment in the renovated space will start in the first quarter of 2024.

Full-length story can be found on the engineering news website.

Purdue launches nation’s first Institute for Physical AI (IPAI)

As student interests in computing-related majors and societal impact of AI and chips continue to rise rapidly, Purdue University has announced a major initiative, Purdue Computes

Purdue Computes consists of three pillars: academic resource of computing departments, strategic artificial intelligence research, and semiconductor education and research.

First Pillar: Academic resource of computing departments

A wave of top-notch hirings will bring 50 new faculty to computer science, computer engineering and related departments in the next five years, with a goal of reaching top 10 in the U.S. In addition, the Department of Computer Science in the College of Science will have a secondary affiliation in the College of Engineering, further enhancing collaboration opportunities with faculty and students. Bi-collegiate collaboration efforts are a proven benefit, following the model of Agricultural and Biological Engineering, which ranks No. 1 nationally. Productive collaboration with computer engineering in the Elmore Family School of Electrical and Computer Engineering, which offers a minor in AI applications, will be carried out.

Second Pillar: Purdue launches nation’s first Institute for Physical AI (IPAI), recruiting 50 new faculty

At the intersection between the virtual and the physical, Purdue will leapfrog to prominence between the bytes of AI and the atoms of growing, making and moving things: the university's and state of Indiana's long-standing strength.

The Purdue Institute for Physical AI (IPAI) will be the cornerstone of the university’s unprecedented push into bytes-meet-atoms research. By developing both foundational AI and its applications to “We Grow, We Make, We Move,” faculty will transform AI development through physical applications and vice versa. IPAI’s creation is based on extensive faculty input and the unique strength of research excellence at Purdue. Open agricultural data, neuromorphic computing, deepfake detection, edge AI systems, smart transportation data, and AI-based manufacturing are among the variety of cutting-edge topics to be explored by IPAI through several current and emerging university research centers. The centers are the backbone of the IPAI, building upon Purdue’s existing and developing AI and cybersecurity strengths as well as workforce development. New degrees and certificates for both residential and online students will be developed for students interested in physical AI.

Third Pillar: Semiconductor facilities and equipment

The third pillar draws together computing, AI and their reliance on semiconductor chips. The university plans to invest $100 million in semiconductor facilities, with Phase 1 of $49 million approved in April 14 by the Board of Trustees for capital project and equipment procurement to upgrade the 20-year-old national treasure Birck Nanotechnology Center. This further illustrates Purdue’s dominant position today in education, research and industry partnership in semiconductors.

Full-length story can be found on engineering website.

1. An innovation ecosystem refers to facilities of other related technical fields within close location proximity.

(Photo credit: Purdue University)

(Photo credit: Purdue University | Yash Trivedi)

(Photo credit: Purdue University)

(Photo credit: Purdue University)

Purdue Institute for Physical AI Includes:

- A steering committee of 17 faculty members featuring a multidisciplinary group of individuals from many of Purdue’s colleges and departments across campus.

- An advisory board consisting of alumni in leadership positions throughout the AI industry. This includes Tesla, Intel, Apple and Ring.

- The recruitment of 50 new faculty during the next five years, tenure-homed at departments in colleges throughout the campus while holding affiliation with IPAI. This addition will be bolstered by 250 Presidential Doctoral Excellence Awards to be deployed to recruit the best PhD students in the field over the same period.

- Industry collaboration with Eli Lilly and Company, on AI in drug discovery and pharmaceutical manufacturing, and High Alpha, on AI-based startup creation — two of the Indiana industries that will partner with the university, especially in joint research-talent recruiting and workforce development.

10 minutes to read

Banner image: In a symbolic effort to inspire our readers, the communications team incorporated AI into the design of the golden semiconductor. It was created using MidJourney, an AI program that incorporates the same research that is currently being expanded upon at Purdue University.

Purdue University is uniquely positioned to offer a full range of options for partners interested in semiconductors and microelectronics: research and development, workforce development, and business growth.

All full-length stories can be found on the semiconductors website.

Purdue, TSMC extend

Purdue University has continued to advance semiconductor workforce development by renewing a strong partnership between industry leader Taiwan Semiconductor Manufacturing Co. and the university’s Center for Secure Microelectronics Ecosystem (CSME).

The renewal of TSMC’s membership in CSME represents the desire by both sides to expand their collaborative scope through additional workforce development and research programs through 2031. CSME started in 2021 as a first-of-its-kind global partnership of academia; industry, including TSMC; and government to advance research and workforce development in designing secure microelectronics.

The memorandum of understanding is the latest in a series of recent Purdue partnership agreements that expand the University’s global reach in the semiconductor industry, including three transformative agreements signed in May 2023.

“As America’s leading semiconductor university in workforce, research and industry partnership, Purdue is excited to renew, update and expand the collaboration with TSMC, especially in light of the recently announced joint activities with key engineering universities in Taiwan in this area,” Purdue President Mung Chiang said. “This is now the fourth global partnership in less than two months — including Belgium, India and Japan — that Purdue has formed to enhance our commitment to the semiconductor ecosystem.”

As part of the partnership extension, TSMC and Purdue will work in tandem on additional educational and research projects. Additional workforce development activities, graduate fellowships and research assistantships are included in the new agreement.

The agreement is the latest as part of the Semiconductors@Purdue initiative, which addresses research and workforce and economic development. TSMC is one of the world’s largest semiconductor contract manufacturers.

Since 2022, investments in the future workforce and semiconductor research have also drawn innovative neighbors to Purdue. U.S.-owned semiconductor manufacturer SkyWater Technology and Taiwan’s MediaTek Inc., the world’s fourth-largest chip designer by revenue, have each in the last year announced partnerships with Purdue.

Purdue’s Semiconductor Degrees Program addresses the needs of the commercial semiconductor industry by working in close collaboration with 27 senior leaders of the semiconductor industry. The program is a model curriculum to address the critical shortage of talent faced by the U.S. semiconductor industry.

Purdue-Japan landmark agreement to establish ‘UPWARDS Network’

Purdue University President Mung Chiang at the G7 Summit in Hiroshima, Japan, signed another landmark international agreement to advance Purdue’s efforts in semiconductors production. Purdue is partnering with Micron, Tokyo Electron and other educational institutions in the U.S. and Japan to establish the “UPWARDS Network” for workforce advancement and research and development in semiconductors.

(Photo credit: Purdue University)Purdue leadership forms task force to take growing semiconductors program to next level

The President’s Semiconductor Task Force will coordinate and lead Purdue’s efforts toward innovative research and development through the CHIPS for America and Science Act approved in Washington, D.C., last year. Leading the task force is Mark Lundstrom, the Don and Carol Scifres Distinguished Professor of Electrical and Computer Engineering, as chief semiconductor officer for Purdue and senior advisor to President Mung Chiang.

(Photo credit: Purdue University)Purdue hosts inaugural USA-India Semiconductor Collaborative

Nearly 36 representatives from leading U.S. tech companies and Indian government officials took part in the inaugural USA-India Semiconductor Collaborative, hosted by Purdue and semiconductor industry organization SEMI in Washington, D.C. The event coincided with the official state visit of Indian Prime Minister Narendra Modi.

(Photo credit: Purdue University | Pooja Chaudhary)Visit by delegation of Taiwan university, industry partners builds on semiconductor collaborations

Purdue President Mung Chiang and Chi-Hung Lin, president of Taiwans National Yang Ming Chiao Tung University, signed an MOU to partner in academic research and workforce development efforts in semiconductors.

(Photo credit: Purdue University | Vincent Walter)Chi-Hung Lin presents a gift to Arvind Raman, dean of College of Engineering.

(Photo credit: Purdue University)Purdue convenes CHIPS summit in D.C. with Sec. Gina Raimondo and Sen. Todd Young, announces sustainability index and facility investment

Leaders from industry, government and academia convened at a summit in April in Washington, D.C., to forge national solutions at scale to address the future of U.S. innovation in microelectronics and the semiconductor workforce.

(Photo credit: Purdue University)Purdue signs tech-focused MOUs with Taiwan universities

Purdue University and the Krach Institute for Tech Diplomacy at Purdue on June 15 signed memorandums of understanding with two research universities in Taiwan, the worlds largest producer of microchips. The MOUs are in partnership with research universities in Taiwan: National Yang Ming Chiao Tung University (NYCU) in Hsinchu and National Chengchi University (NCCU), a public research university in Taipei.

From left, Keith Krach, co-founder of the Krach Institute for Tech Diplomacy; Purdue President Mung Chiang; Chi-Hung Lin, president of National Yang Ming Chiao Tung University; and Bi-khim Hsiao, Taiwan's representative to the U.S.

(Photo credit: Purdue University | Rebecca Robiños)Purdue partners with European-based semiconductor research and development innovation hub

Business, governmental and Purdue leaders took part in an announcement of a partnership between European-based imec and Purdue University.

Pictured from left are Joe Pasetti, imec vice president of corporate affairs; Jimmy Costa, senior vice president of innovation and semiconductor strategy, Applied Research Institute Inc.; Max Mirgoli, imec executive vice president of worldwide strategic partnerships; Mark Lundstrom, Purdue's chief semiconductor officer and senior advisor to the university president; Purdue President Mung Chiang; Indiana Secretary of Commerce Brad Chambers; U.S. Sen. Todd Young; Indiana Gov. Eric Holcomb; imec CEO Luc Van Den Hove; and Jillian Turner, senior vice president, global investment and partnerships, Indiana Economic Development Corporation.

(Photo credit: Purdue University)STARS: Summer program helps students develop skills for growing semiconductor industry

The new: Purdue Summer Training, Awareness, and Readiness for Semiconductors (STARS) program already has received support from key players in the semiconductor industry, including Intel, Cisco, GlobalFoundries, SK hynix, TI, L3Harris, Western Digital and Synopsys.

(Photo credit: Purdue University)

(Photo credit: Purdue University | Vincent Walter)

AT THE FOREFRONT OF ADVANCEMENTS IN ENGINEERING

Purdue offers a comprehensive set of interdisciplinary degrees and credentials in semiconductors and microelectronics to students across the university

U.S. economic security critically depends on developing a talent pipeline in this vital field. Purdue research in semiconductors spans the “full stack” from facilities to materials and devices, circuits, systems, and architecture. Join us as we continue advancing our national leadership in semiconductor education and workforce development.

(Photo credit: Purdue University)

"Now is the silicon moment for America again. We can only afford to rise to the challenge."

Mung Chiang | President of Purdue University and the Roscoe H. George Distinguished Professor of Electrical and Computer Engineering

(Photo credit: Purdue University | John Underwood)

10 minutes to read

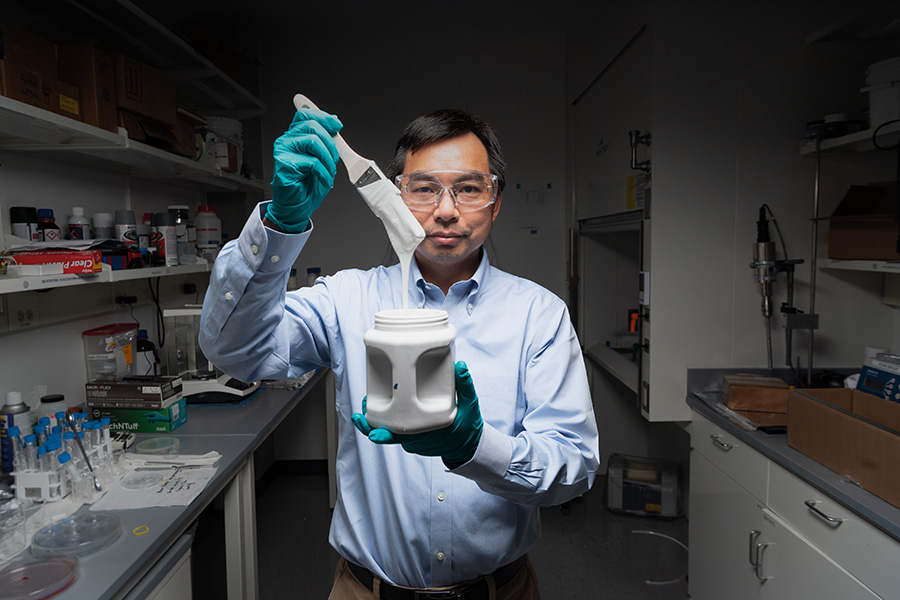

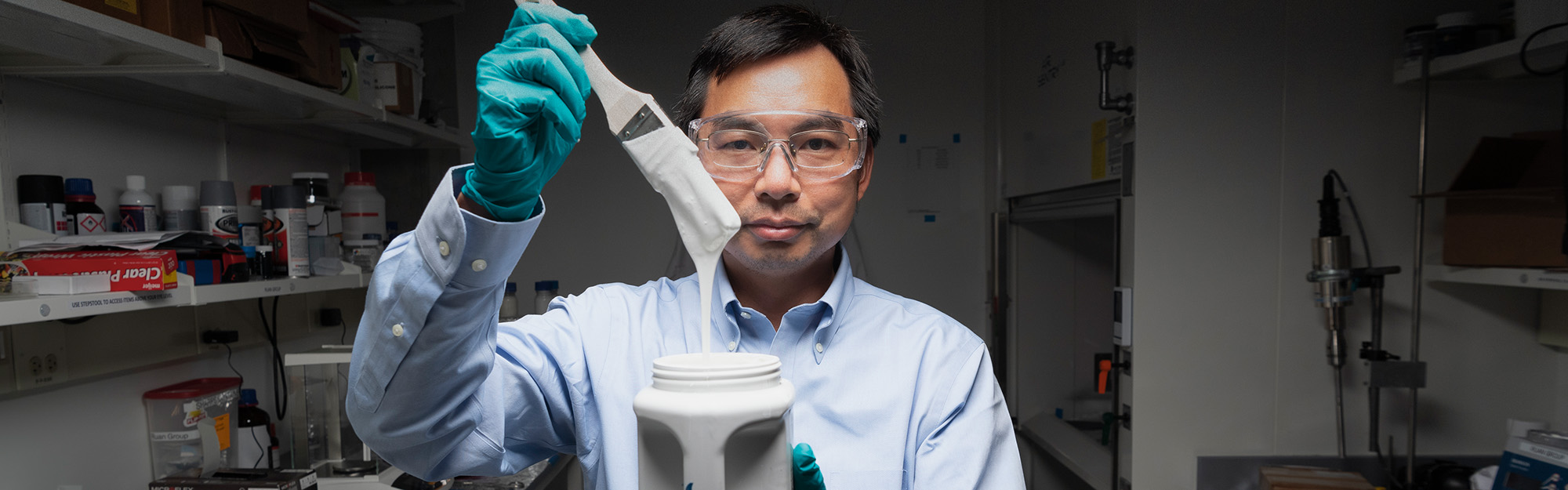

Banner image: Xiulin Ruan, a professor of mechanical engineering, holds up his lab’s sample of the whitest paint on record.

Purdue’s ‘world’s whitest paint’ wins 2023 SXSW Innovation Award

Technology tops sustainability category for world-changing potential

The world’s whitest paint, developed by Purdue University researchers and recognized in Guinness World Records, has been named the winner of the 2023 Innovation Award in the sustainability category by South by Southwest Conference & Festivals (SXSW).

The award “recognizes the most exciting creative developments in the connected world,” and was presented to Purdue in March at the 25th annual SXSW Innovation Awards Ceremony in Austin, Texas. Purdue was chosen in the sustainability category from among four finalists that included another Purdue candidate.

The paint, developed by Purdue Professor of Mechanical Engineering Xiulin Ruan, is fighting global warming by keeping surfaces cool enough to reduce the need for internal air conditioning. SXSW is the latest to recognize the innovation, which was previously featured on "PBS NewsHour" and "The Late Show With Stephen Colbert". Also in March, the paint was named winner of the 2023 Gizmodo Science Fair.

In 2022, Ruan and his team innovated further by developing a new formulation of his groundbreaking paint that is now thinner and lighter – ideal for radiating heat away from cars, trains, airplanes and even spacecraft. According to Ruan and his team’s models, Covering 1% of the Earth’s surface in their technology could mitigate the total effects of global warming, a fact encouraging them to continue pursuing formulas suitable for surfaces like asphalt and roadways.

Painting the town white to go green

Typical commercial white paint gets warmer rather than cooler when subjected to sunlight or other light sources. Paints on the market that are designed to reject heat reflect only 80% to 90% of sunlight and can’t make surfaces cooler than their surroundings. In comparison, the world’s whitest paint reflects 98.1% of solar heat away from its surface.

Because the paint absorbs less heat from the sun than it emits, a surface coated with this paint is cooled below the surrounding temperature without consuming power. Using this formulation to cover a roof area of about 1,000 square feet could result in a cooling power of 10 kilowatts, more powerful than the air conditioners used by most houses.

While Ruan’s original paint formula is massively efficient, it required a layer 0.4 millimeters thick to achieve subambient radiant cooling. The newer, thinner formulation can achieve similar cooling with a layer just 0.15 millimeters thick.

The new paint also incorporates voids of air, which make it highly porous. This lower density, together with the thinness, provides another huge benefit: reduced weight. The newer paint weighs 80% less than the original paint yet achieves nearly identical solar reflectance – 97.9%, compared with the original formula’s 98.1%.

Ruan and his team of researchers are currently working with the Purdue Research Foundation’s Office of Technology Commercialization to bring their technology to market.

Full-length story can be found on the semiconductor website.

ICON co-directors Mou, Sundaram to lead Saab-ONR project aimed at enhancing battlespace threat awareness

The Office of Naval Research (ONR) has selected Purdue University to partner with Saab on the development of next-wave artificial intelligence capabilities to increase battlespace situational awareness by automatically detecting and characterizing threats in complex environments

The Threat and Situational Understanding with Networked-Online Machine Intelligence (TSUNOMI) program will capitalize on Saab’s growing presence in West Lafayette, leveraging its advanced manufacturing facility and engineering resources. While the technologies developed through TSUNOMI are first intended for transition to a naval unmanned surface vessel, they are extensible to other markets, such as military radar systems and commercial airport applications that are complementary to Saab’s growing portfolio in the U.S., according to a Saab release.

The total grant from ONR to Saab is approximately $13 million, of which an anticipated $4.3 million will filter to Purdue as a four-year subcontract through Saab.

Co-principal investigators for the project are Shaoshuai Mou, the Elmer Bruhn Associate Professor of Aeronautics and Astronautics, and Shreyas Sundaram, the Marie Gordon Associate Professor in the Elmore Family School of Electrical and Computer Engineering. Both professors serve as co-directors of Purdue’s Institute for Control, Optimization and Networks (ICON), launched in 2020.

TSUNOMI comes at a time when serious physical attacks on critical infrastructure and intrusions into sensitive areas, in both military and civilian domains, are increasing, Sundaram said.

“There is an urgent need to create technological solutions that allow networks of sensors equipped with sophisticated AI to quickly detect and identify potential threats,” said Arvind Raman, the John A. Edwardson Dean of the College of Engineering.

ICON, which includes 84 faculty from across the College of Engineering, College of Science, College of Agriculture and Purdue Polytechnic Institute, was a natural choice for Saab, Sundaram said.

The objective of the TSUNOMI research is to develop an explainable machine learning framework with multimodal automatic target recognition and sensor resource management for early warning and situational awareness from surface vessels equipped with an automated verification and validation machine learning pipeline.

TSUNOMI is ICON’s first large initiative with Saab and under support from the Office of Naval Research (ONR). “TSUNOMI is a great win for the Saab and Purdue partnership,” said Erik Smith, president and CEO of Saab. “This program represents a real step toward robust and trusted artificial intelligence. TSUNOMI will help stakeholders make decisions quicker and with more confidence.”

Purdue’s funding will primarily be used to support graduate students on the project, as well as some faculty time. Part of the award also will be used to purchase sensors.

Full-length story can be found on the engineering news website.

Air-conditioning the battlefield

There’s a battle going on to create more efficient and environmentally friendly refrigeration and air-conditioning systems

But what if those systems are needed on an actual battlefield? The U.S. Department of Defense (DOD) has enlisted Purdue University researchers to explore refrigerants that are both sustainable and safe to operate in combat conditions.

“The DOD has a big problem to solve,” said Davide Ziviani, assistant professor of mechanical engineering and associate director of the Center for High Performance Buildings. “They have thousands of vehicles with traditional air-conditioning systems, like those used in your car or truck. But military vehicles face unique situations, where current systems might pose an increased challenge on the battlefield. One of our goals is to find refrigerants that are both environmentally friendly and safe to operate in combat.”

Ziviani is leading a team that has received a three-year, $1.9 million grant from the Strategic Environmental Research and Development Program (SERDP), a program designed to increase the DOD’s environmental resilience.

“Here at Purdue, we have the largest academic HVAC lab in the world: Herrick Labs,” said Ziviani. “We are constantly researching the latest refrigeration and air-conditioning systems, so we are perfectly set up to tackle this challenge.”

One unique feature of Herrick Labs is its psychrometric chambers, large rooms where air-conditioning and heating systems can be put through their paces. These chambers simulate the extreme conditions that military vehicles might encounter, from arid deserts and humid jungles to polar winters. Two of Herrick’s psychrometric chambers have been built to test flammable refrigerants and other specialty systems that can’t be tested elsewhere.

The other aspect that makes Purdue the perfect choice for this niche of research is Zucrow Labs, the largest academic propulsion lab in the world. “Steve Son has one of the few academic labs in the world devoted to energetic materials,” Ziviani said. “He can safely simulate situations where these systems are exposed to fire, explosions and other military-style threats.”

Full-length story can be found on the engineering news website.

Purdue celebrates Air Force Research Laboratory’s Regional Hub Network – Midwest to further research and development in areas of national security

Leaders from Purdue University and the Air Force Research Laboratory (AFRL) gathered in April for the ribbon-cutting ceremony celebrating the AFRL Regional Hub Network – Midwest, located on Purdue’s West Lafayette campus

Through the Regional Hub Network, AFRL scientists and engineers engage and collaborate with universities, small and large businesses, other government agencies, and venture capitalists to assemble a new science and technology ecosystem in which partners help the lab research high-risk case studies. The goals of this collaboration are to leverage research, translation and workforce development successes across the U.S., encourage science and technology exchanges, and drive innovation.

In February 2022, Purdue was selected as one of two lead universities in the country and headquarter locations for the AFRL Regional Hub Network. The network includes more than 60 academic and industrial partners from across 12 Midwest states. Cornell University is the academic lead and headquarters location for the AFRL Regional Research Hub – Mid-Atlantic.

Purdue’s hub will host space for AFRL staff members to work on special projects that further research efforts and national security for the U.S.

As the Midwest lead, Purdue is tasked with developing a region-specific science and technology roadmap; piloting partnership models with programmatic interventions, adopting and implementing best practices with a focus on expansion and identifying pathways for long-term impact on the science and technology ecosystem of the U.S. Air Force/Space Force.

Full-length story can be found on the engineering news website.

ISE Magazine: Humanitarian supply chains get 'LASER' focus with Yuehwern Yih

The intersecting needs of healthcare, supply chain logistics and humanitarian aid have led an industrial and systems engineering faculty member into a rewarding career path

IISE member and Fellow Yuehwern Yih, professor in the School of Industrial Engineering at Purdue University, has been involved in applying her Industrial and Systems Engineering (ISE) skills to assist humanitarian aid organizations to improve their processes while offering assistance in countries stricken by poverty and disasters. She currently serves as academic director [now director] of LASER PULSE, a $70 million program funded by USAID’s Innovation, Technology and Research Hub. Purdue University won this award in 2018 over more than 100 submissions. Catholic Relief Services, Indiana University, Makerere University and the University of Notre Dame are consortium partners. Its aim is to provide research-driven solutions to achieve Sustainable Development Goals (SDGs) through cross-sector partnerships, localization and research translation. The program comprises a network of more than 3,500 researchers and development professionals in 74 countries seeking to find innovative solutions to overcome global challenges.

In 2015, Arvind Raman, then executive associate dean for the College of Engineering, invited her to join another effort.

Yih and Dawei Wang, her former PhD student, worked closely with CRS first responders and humanitarian assistance specialists to analyze the workflow. They then developed the cloud-based, multiplatform, supply chain management system called ETRA (Electronic TRAnsparent TRAcking) to connect warehouses across different country programs, request and approve relief materials, check inventory, track materials from donors to beneficiaries and generate accounting and beneficiary reports.

ETRA aims to track humanitarian commodities more efficiently and accurately to foster transparency and accountability throughout the supply chain. “This research has to be translational,” Yih said. “It’s not helpful unless it can be used by the people doing the humanitarian work every day. It can’t just be a theory. It’s about addressing the need in the field.”

ETRA was field tested in the Dominican Republic in 2018 and is currently licensed through Purdue and fully deployed in two countries, South Sudan and Ukraine, for humanitarian response.

In parallel, Yih joined with ResilientAfrica Network (RAN) at Makerere University and Management Sciences for Health (MSH) developed E+TRA Health to bridge the data gaps in the supply chain of medications and laboratory supplies in Uganda. They collaborated with local care providers in Mukono District to address medication shortages and focus on 13 essential maternal and child health commodities to ensure safe and healthy childbirth. E+TRA Health was deployed in a pilot program in two health centers in 2019 in Uganda.

Yih’s health supply chain efforts earned an award from the Melinda and Bill Gates Grand Challenge, one of 51 awarded out of 1,500-plus proposals from more than 50 countries. Purdue PhD student Rhoann Kerh won the Global Good by Intellectual Ventures award for her poster on the project at the Purdue Engineering I2D Exposition for Global Programs and Partnerships in Engineering in 2018.

LASER PULSE ‘another new territory to apply ISE principles’

LASER PULSE collaborates with USAID missions, bureaus and independent offices and other stakeholders to identify areas in need of improvement. Its mission is to provide the necessary resources for teams of researchers and practitioners to design development research that is relevant and usable to inform policies and practices.

As academic leadership, Yih oversees the technical aspects and system design of this program to continue improving its operations and adapting to unexpected events with a system lens and user-centered design principles.

In addition to outcomes of the research projects, the LASER PULSE program is designed to systematically transform how the research is identified, conducted, translated and disseminated to inform evidence-based policymaking and practices in global development with consideration of sustainability and localization.

LASER PULSE currently funds 47 research projects in 19 lower-and-middle-income countries (LMICs) including South Sudan, Kenya, Uganda, Somalia, Tanzania, Democratic Republic of the Congo, Nepal, Laos, Vietnam, Nepal, Malawi, Iraq and Colombia. The research topics cover a wide variety of USAID sectors, such as nutrition/food security, education, youth development, humanitarian assistance and violence and conflict prevention.

This year, Yih was selected for the 2023 Outstanding Leadership in Globalization Award at Purdue for her commitment to humanitarian aid and global development.

Reprinted with permission of ISE magazine.

(Photo credit: U.S. Navy)

Each Purdue investigator will bring expertise in a core area of the overall problem

- Shaoshuai Mou, co-principal investigator, will develop algorithms for intent classification and threat evaluation.

- Shreyas Sundaram, co-investigator, will work on a sensor resource management engine that will guide the appropriate selection and deployment of sensors.

- Dan DeLaurentis, aeronautical and astronautical professor and vice president for research institutes and centers, will serve as technical advisor to the team, bringing his expertise in systems-of-systems analysis and design, as well as decades of experience in delivering effective solutions for military applications.

- James Goppert is the managing director of Purdue UAS Research and Test Facility, where key experiments will be performed and the algorithms will be validated.

- Christopher Brinton, Elmore Assistant Professor of Electrical and Computer Engineering, will lead the development of federated learning algorithms, which control how knowledge gained from individual AI systems is aggregated and shared. He will also serve as a technical lead for the project.

- David Inouye, assistant professor of electrical and computer engineering, is an expert on explainable AI and will help ensure that the outputs of the target recognition algorithms are interpretable by humans.

- Michael Zoltowski, the Thomas J. and Wendy Engibous Professor of Electrical and Computer Engineering, is a leading expert on radar systems and will contribute to ensuring that critical sensors can be integrated into the overall TSUNOMI architecture.

- Song Zhang, assistant head for experiential learning and mechanical engineering professor, will provide expertise on sensor fusion and tracking algorithms.

- Carl Huetteman, managing director of special initiatives for the College of Engineering, will serve as project manager for the team, coordinating with Saab and ONR to keep deliverables and outcomes on track.

(Photo credit: U.S. Air Force | Senior Airman Jimmie D. Pike)

(Photo credit: Purdue University | Kelsey Lefever)

(Photo credit: Purdue University)

(Photo credit: Purdue University)

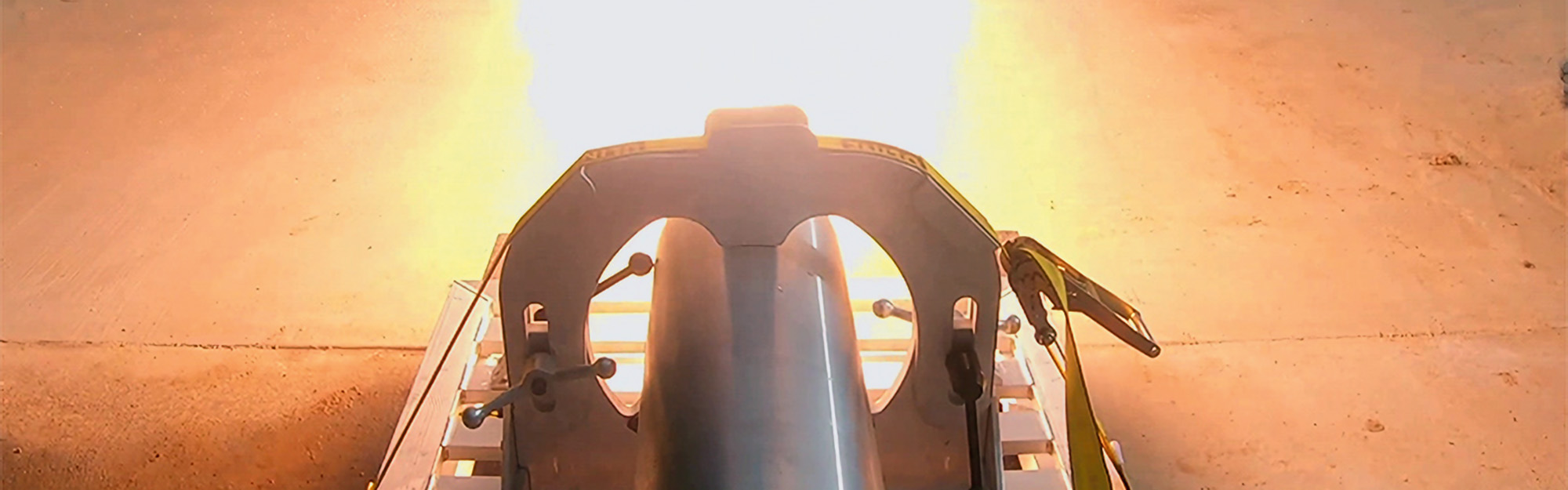

Purdue-launched solid rocket motor-maker Adranos flies off with Anduril (Photo credit: Adranos Inc.)

10 minutes to read

Banner image: Purdue-affiliated startup Adranos, manufacturer of solid rocket motors and maker of ALITEC, a high-performance solid rocket fuel that gives greater payload capacity, range and speed to launch systems, has been sold to Anduril Industries.

Adranos Inc., a Purdue-originated company that grew from a doctoral project into an impactful company, has been acquired by a major Costa Mesa, California-based defense products company, Anduril Industries.

Brielle Terry invented ALITEC in 2015 while she was a postdoctoral student in Purdue’s School of Aeronautics and Astronautics and continued her work at Purdue’s School of Mechanical Engineering. With help from Chris Stoker, an MBA graduate and Doctor of Law from Indiana University, Terry created business plans for ALITEC, a more powerful and more efficient solid rocket fuel that is also less damaging to the environment. Stoker and Terry went on to co-found Adranos, where Stoker is CEO and Terry is chief technology officer.

After the company was founded, Adranos participated in Purdue Innovates’ accelerator program in the Startup Foundry, and leveraged connections with the Foundry’s alumni network, receiving guidance from Purdue alumni who had expertise in the defense and space industry.

Adranos broke ground on a rocket fuel production facility in 2020 at Purdue Research Park. The company received financial support from the Purdue Research Foundation and the Indiana Economic Development Corp. to construct the facility, which opened in West Lafayette in September 2022. Adranos also has a solid rocket motor production facility in Mississippi and an engineering office in Alabama.

Full-length story can be found on the purdue news website.

Purdue’s ‘talking concrete’ embedded into new I-465 and I-69 interchange in Indianapolis

Purdue researchers, Indiana Department of Transportation crews and WaveLogix installed concrete sensors invented by Luna Lu, the Reilly Professor of Civil Engineering, into the future I-465 interchange to I-69 south on Indianapolis’ south side in July. The invention will soon give engineers real-time data from Indianapolis’ newest interstate section, potentially preventing potholes, reducing construction traffic jams, and saving taxpayer dollars spent on road repairs.

Full-length story can be found on the engineering news website.

Building the first highway segment that can charge vehicles as they drive

Purdue Engineering professors, from left, John Haddock, Nadia Gkritza, Dionysios Aliprantis and Steve Pekarek stand in the lab where they are testing technology they designed to enable electric vehicles to receive power from the road.

Full-length story can be found on the engineering news website.

Bringing the latest in medical technologies to the youngest patients

Purdue University, the Indiana University School of Medicine and medical device company Cook Medical are forming a new alliance — the Crossroads Pediatric Device Consortium. These partners will focus on meeting needs for pediatric patients by accelerating the development, approval and availability of innovative medical devices for children.

Full-length story can be found on the engineering news website.

Purdue startup Aerovy Mobility develops cloud software to support infrastructure for electric aircraft

The advanced air mobility sector includes urban air mobility, which uses electrical vertical takeoff and landing vehicles. Aerovy Mobility, a Purdue University-connected startup, has developed software solutions to benefit airport and vertiport operators and real estate developers looking to establish advanced air mobility technology at existing and potential sites.

Full-length story can be found on the engineering news website.

Changing lives through inventions:

Purdue jumps to top 5 of global leaders in U.S. patents received

In 2022, the Purdue Research Foundation received an impressive 192 patents from the U.S. Patent and Trademark Office (USPTO), placing it fifth internationally. Purdue College of Engineering accounted for 66 percent of those patents. Purdue’s top-five breakthrough comes on the heels of Purdue’s No. 6 ranking in both 2020 and 2021, when it received 175 and 169 patents, respectively.

(Photo credit: Purdue University)

(Photo credit: Purdue University | Vincent Walter)

(Photo credit: Photo provided)

(Image credit: Electro.Aero)

Five alumni elected to the National Academy of Engineering

10 minutes to read

5 Engineering Alumni Elected to National Academy of Engineering – among the highest professional distinctions accorded to an engineer.

Five Purdue College of Engineering alumni are among 106 new members and 18 international members in the latest class. Individuals in the newly elected class will be formally inducted during the NAE’s annual meeting on Oct. 1, 2023.

Ramalingam Chellappa

MSEE '78, PhD '81

Ramalingam Chellappa (MSEE 78, PhD 81) was elected for contributions to digital image analysis, automatic face recognition and applications. Chellappa is the Bloomberg Distinguished Professor in the Department of Electrical and Computer Engineering at Johns Hopkins University.

Jennifer Sinclair Curtis

BSChE '83

A distinguished professor in the Department of Chemical Engineering at the University of California, Davis,Jennifer Sinclair Curtis (BSChE 83) was recognized for work on particle-laden flows and industrially used algorithms for dilute and dense-phase gas-solid flow.

Deborah Grubbe

BSChE '77

Deborah Grubbe (BSChE 77) was recognized for contributions and leadership to improve engineering safety practices in the chemical process industries. Grubbe is president and owner of Operations and Safety Solutions LLC.

Douglas Owen

BSCE '80

Douglas Owen (BSCE 68), senior principal at Stantec, was selected for contributions to drinking water quality, expansion of potable reuse and integration of sustainability in water treatment plant design.

Anil Sachdev

MSMSE '72

General Motors Principal Technical Fellow and Lab Group ManagerAnil Sachdev (MSMSE 72) was honored for the research, development and commercialization of lightweight materials to improve vehicle fuel economy.

Introduction