Faculty receive funding for new response approaches to pandemic

Purdue faculty members recently received funding from the American Rescue Plan (ARP) for their coronavirus response project proposals.

ARP is part of the National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL), which in December identified 32 projects that will help the nation prevent, prepare for, and respond to coronavirus public health threats.

The Purdue projects and affiliated faculty are as follows:

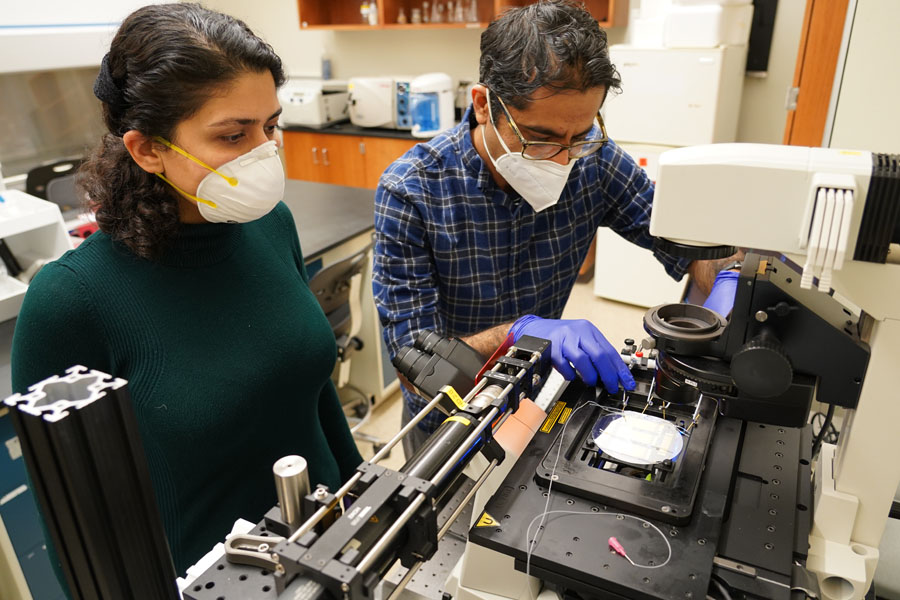

Spectro-acoustic process analytical technology for continuous manufacturing of coronavirus vaccine

Project director and Principal Investigator (PI):

Co-PIs:

The goal of the project is to develop new process analytical technology (PAT) for the detection and quantification of virus-like particles and attenuated live viruses.

Ardekani’s project addresses the nation’s response for large-scale vaccine manufacturing demands during the COVID-19 pandemic by improving quality control tools. Funding will enable an accurate detection and quantification platform that is expected to have a significant impact on enhancing the production quality of multiple types of vaccines and prepare researchers for future outbreaks.

“The COVID-19 pandemic has highlighted the need for rapid production of vaccines and consequently continuous in-process monitoring of virus particles. Our proposed technology enables real-time quantification of attenuated live viruses and virus-like particles necessary for continuous manufacturing,” Ardekani said.

Advanced characterization and manufacturing for mRNA vaccines

Principal Investigator (PI): Eric Munson, the Dane O. Kildsig Chair in Industrial and Physical Pharmacy and department head

Additional team members:

•Alina Alexeenko, professor in the School of Aeronautics and Astronautics and the Davidson School of Chemical Engineering, and associate dean of undergraduate education in the College of Engineering

•Elizabeth Topp, professor of industrial and physical pharmacy and chief scientific officer, National Institute for Bioprocessing Research and Training (NIBRT), Dublin, Ireland

•Qi (Tony) Zhou, associate professor of industrial and physical pharmacy

The goal of this proposal is to develop new formulation and manufacturing methods that will lead to improved stability of vaccines, specifically mRNA-lipid nanoparticle (mRNA-LNP) complexes, and potentially other applicable vaccines and biologics formulations.

The rapid deployment of mRNA vaccines forced the use of frozen solution formulations that must be shipped and stored at ultracold temperatures. This method can increase the risk of inactivation between the manufacturing site and the patient, strain distribution networks and logistics, and compromise global access. Munson’s project will develop mRNA vaccines with improved long-term stability, faster development and manufacturing, and less reliance on the cold chain.

“We are excited to work on improving the stability of mRNA vaccines so that they will not have to be stored at extremely cold temperatures,” Munson said. “Purdue has the analytical, formulation, and manufacturing skills to help understand and improve the current generation of mRNA vaccines, and also develop the knowledge toolkit for preparing vaccines to deal with future outbreaks.” The highly interdisciplinary collaboration also will apply unique lyophilization and nanoscale characterization capabilities at Purdue’s Birck Nanotechnology Center.