Purdue biomedical engineering students develop hands-on, realistic breastfeeding simulation to train perinatal professionals

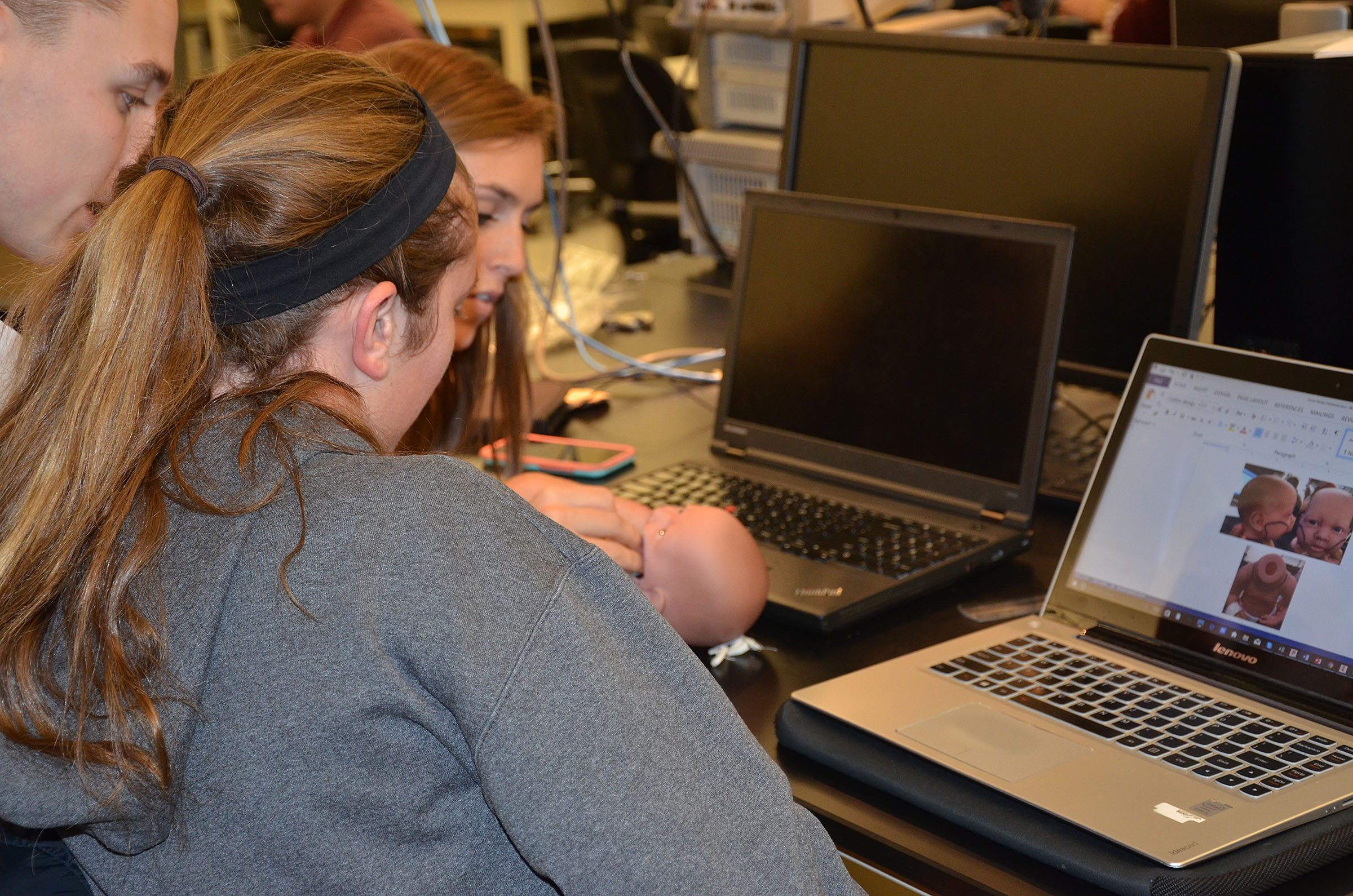

Neal Patel, Jennifer Ray, Alexandria Sacopulos and Daniel Romary co-invented Martina: A Breastfeeding Simulation System for their senior design project in biomedical engineering. Tina Babbitt, an Indiana Perinatal Network nurse and lactation consultant, detailed the need for better breastfeeding training materials to Purdue and mentored the researchers throughout development.

“One motivation was that many new mothers stop breastfeeding earlier than recommended, due to pain or discomfort from poor placement,” said Romary, the project spokesman. “If we could help new moms better understand how to breastfeed, they could do it correctly and longer without pain. Also, the recommended six months has been shown to have health benefits for the baby.”

According to the Centers for Disease Control and Prevention, only 11.9 percent of babies are breastfed for the recommended six-month period. Mothers stop breastfeeding early due to discomfort or poor technique. The researchers strive to solve this problem by better preparing perinatal nurses and professionals in breastfeeding techniques.

Currently, breastfeeding training materials available to nurses are printed on paper or don’t have a realistic feel. For example, doll-based simulators do not account for realistic challenges such as supporting the baby’s head during a feeding. However, Martina’s systems use its sensors, motors and lights to guide training nurses step-by-step through the appropriate breastfeeding procedure.

“We designed the device for nurses, so that they better understand how to teach new moms to breastfeed,” Romary said. “They learn the important checkpoints of breastfeeding. For example, they have to correctly orient the baby and make sure the nipple goes far enough into the baby’s mouth.”

The Purdue Office of Technology Commercializationhas a patent pending on this technology. The researchers aim to further refine the existing prototype by finding a partner with manufacturing capabilities.

“We see our system as the first device to combine hands-on practice with anatomical correctness in a cost-effective way,” Romary said.