Design Optimization and Evolutionary Computing

The design of power engineering components such as inductors, transformers, and especially rotating electric machinery has been a central theme of Purdue’s power engineering program in recent years. To this end, Purdue distinguishes itself by a rigorous and systematic approach to the engineering design. In order to explain this process, consider a fairly conventional design process shown below. This process often begins with a basic analysis of the design performance or objectives in terms of design variables (the search space). Unfortunately, it is almost universally the case that this analysis cannot be inverted; i.e. while it may be possible to predict design metrics given the design variables, it is difficult to determine the design variables in terms of the design metrics. As a result, design equations are determined based on ‘rules of thumb’ loosely based on a drastic simplification of the original analysis. Because of these approximations, the designer typically checks the design using numerical analysis codes such as finite element analysis. Based on the results of the numerical analysis, the designer then modifies the design and repeats the process. Finally, the designer is satisfied and the design process is complete.

Conventional Design Process

While the conventional design process has proven highly effective, it nevertheless has some deficiencies. First, it is time consuming in terms of engineering time. This makes the design process needlessly slow and expensive. This is particularly problematic in areas such as power engineering wherein the number of designers is severely limited. The second problem is that while the process yields a working design, it does not yield a design which necessarily minimum loss, minimum loss, or optimal in any other performance metric. The design may be the best obtainable. Or it might be quite poor. The designer has little indication of how close the design is to the best achievable performance.

As an alternative to this process, one source of motivation comes Fr. Gegory Mendel (1822-1884) and the other from Chares Darwin (1809-1882). In particular the motivation is the use of the ideas of genetics and natural selection. As it turns out, the use of these ideas as the basis for a computational algorithm leads a power optimization strategy.

Fr. Gregory Mendel

Darwin's ship, the HMS Beagle

Briefly stated, the basic approach is to represent the design variables in a structure which mimics DNA, to establish a base populations of designs (initialized at random), and to allow that population of designs to evolve according to the processes of natural selection. This computational approach is referred to as a genetic or evolutionary algorithm. These algorithms were first developed by John Holland in the late 1960’s and early 1970’s, but perhaps are only now beginning to reach their true potential as a computational algorithm.

In mathematical terms, what this really relates to is formulating the design problem as an optimization problem, in which all design constraints and the design objective(s) are used to synthesize a single or multi-objective fitness function. At this point, it would seem that any optimization algorithm could be used to perform the optimization and thereby establish the design. However, typically the problems considered have a large search space with both continuous and discrete variables, are discontinuous, and are non-convex. Genetic algorithms have proven to be extremely effective at solving this class of (rather unfriendly) problem.

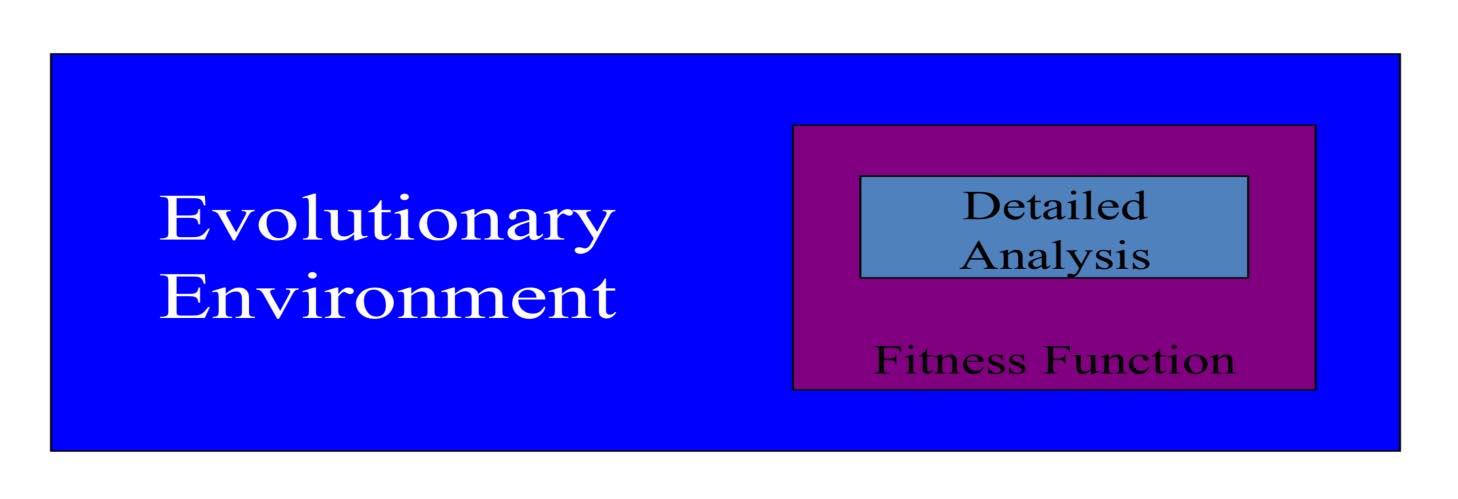

The genetic algorithm based design process is shown below. In this case the engineer is responsible for two aspects; the development of a detailed analysis of the design in terms of the design variable, and the formulation of a fitness function which uses this analysis to evaluate performance metrics subject to design constraints. There is no attempt to invert the analysis as in the case of the conventional design approach. From the engineering perspective, it is only a design problem. At this point the evolutionary algorithm takes over and creates a population of designs which are allowed to evolve according to the rules of natural selection in such a way as to mimic biological evolution. The result is an exciting and effective design process which yields an optimum design (or set of optimal designs in the multi-objective case) with a minimum of human engineering effort.

Evolutionary (Genetic Algorithm Based) Design

Purdue has been intensely active in this design approach, having applied it to a variety of problems including inductor design [1], transformer design, permanent-magnet synchronous machine design [2-3], electromechanical design [4], switched-reluctance machine design, clawpole alternator design, wound-rotor synchronous machine design, switching modulator design [5], and power converter control design [6-7], to name a few.

Purdue researchers have applied the same techniques to the related problem of parameter identification. Examples include brushless exciter parameter identification [8], induction machine parameter identification [9-10], and magnetic material parameter identification [11-12]. Other applications include the use of this technique to stability analysis [13-15], and to warship engineering systems dependability [16].

Besides applications research, Purdue has also been active in algorithm development. The algorithm set forth in [17] is perhaps the most effective means of solving minimax optimization problems yet developed. The Prescribed Robustness Evolutionary Algorithm (PREA) set forth in [18] is the only available algorithm for robust designs that allows the design to specify the probability of success of the design as an independent design specification.

In order to support research and applications in genetic algorithms, Purdue researchers have developed the publically available Genetic Optimization System Engineering Tool code, which is in the form of a MATLAB tool box. They have also set up the Genetic Optimization Processing Array, a 216 node cluster computer dedicated to evolutionary computing applications.

References

[1] J.Cale, S.D. Sudhoff, R.R. Chan, “Ferrimagnetic Inductor Design using Population-Based Design Algorithms,” IEEE Transactions on Magnetics. vol. 45, no. 2, pg(s) 726-734. February 2009.

[2] B.N. Cassimere, S.D. Sudhoff, “Population Based Design of Permanent Magnet Synchronous Machines,” IEEE Transactions on Energy Conversion, vol. 24, no. 2, pg(s) 347-357. June 2009.

[3] S.D. Sudhoff, J. Cale, B. Cassimere, M. Swinney, “Genetic Algorithm Based Design of a Permanent Magnet Synchronous Machine,” 2005 International Electric Machines and Drives Conference, San Antonio, Texas, May 15-18, 2005

[4] B. Cassimere, R. Chan, J. Cale, A. Cramer, S. Sudhoff, “Evolutionary Design of Electromagnetic and Electromechanical Devices,” IEEE Electric Ship Technologies Symposium, Arlington, VA, May 21-23, 2007

[5] Brandon Cassimere, S.D. Sudhoff, Brant Cassimere, M. Swinney, “Time-Domain Design of Motor Drive Current Regulators Using Genetic Algorithms,” 2005 International Electric Machines and Drives Conference, San Antonio, Texas, May 15-18, 2005

[6] R.R. Chan, Y. Lee, S.D. Sudhoff, E.L. Zivi, “Evolutionary Optimization of Power Electronics Based Systems,” IEEE Transactions on Power Electronics, Vol. 23, No. 4, pp. 1907-1917, July 2008.

[7] R. Chan, S.D. Sudhoff, S.H. Żak, Y. Lee, E.L. Zivi, “Evolutionary Optimization of Power Electronics Based Power Systems” 2007 Applied Power Electronics Conference, Anaheim, CA, February 25-March 1, 2007

[8] D.A. Aliprantis, S.D. Sudhoff, B.T. Kuhn, “Genetic Algorithm Based Parameter Identification of a Hysteresis Brushless Exciter Model,” IEEE Transactions on Energy Conversion, vol. 21, no. 1, March 2006, pp. 148-154.

[9] C. Kwon, S.D. Sudhoff, “A Genetic Algorithm Based Induction Machine Characterization Procedure with Application to Maximum Torque Per Amp Control,” IEEE Transactions on Energy Conversion, Vol. 21, No. 2, June 2006, pp. 405-415.

[10] Chunki Kwon, Scott D. Sudhoff, “A Genetic Algorithm Based Induction Machine Characterization Procedure,” 2005 International Electric Machines and Drives Conference, San Antonio, Texas, May 15-18, 2005

[11] J.L. Cale, S.D. Sudhoff, “An Improved Magnetic Characterization Method for Highly Permeable Materials,” IEEE Transactions on Magnetics. Vol. 42, Issue 8, August 2006

[12] J.L. Cale, S.D. Sudhoff, R.R. Chan, "A Field-Extrema Hysteresis Loss Model for High-Frequency Ferrimagnetic Materials," Magnetics, IEEE Transactions on, vol. 44, no. 7, pg(s): 1728-1736, July 2008

[13] B.P. Loop, S.D. Sudhoff, S. H. Zak, E.L. Zivi, “Estimating Regions of Asymptotic Stability of Power Electronics Systems Using Genetic Algorithms,” accepted for IEEE Transactions on Control Systems Technology. (Final Acceptance in July 2009).

[14] Benjamin Loop, S.D Sudhoff, S.H. Zak, E. Zivi, “An Optimization Approach to Estimating Stability Regions Using Genetic Algorithms,” 2005 American Control Conference, 8-10 June 2005, Portland, Oregon.

[15] C. Sullivan, S. Sudhoff, E. Zivi, S. Zak, “Methods of Optimal Lyapunov Function Generation With Application to Power Electronic Converters and Systems,” IEEE Electric Ship Technologies Symposium, Arlington, VA, May 21-23, 2007

[16] A.M. Cramer, S.D. Sudhoff, E.L. Zivi, “Performance Metrics for Electric Warship Integrated Engineering Plant Battle Damage Response,” accepted for IEEE Transactions on Aerospace and Electronics Systems. (Final Acceptance in October 2009).

[17] A.M. Cramer, S.D. Sudhoff, “Evolutionary Algorithms for Minimax Problems in Robust Design,” IEEE Transactions on Evolutionary Computing, vol. 13, no. 2, pg(s). 444-453. April 2009

[18] R.R. Chan, S.D. Sudhoff, “An Evolutionary Computing Approach to Robust Design in the Presence of Uncertainties,” accepted for IEEE Transactions on Evolutionary Computing in October 2009.