Purdue University engineers develop new technology for wireless communication

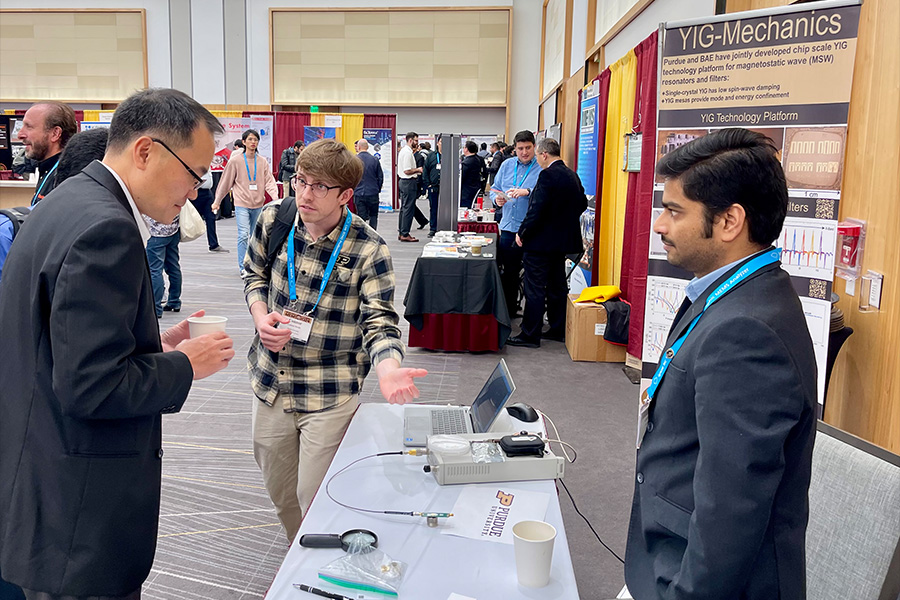

Engineers in the OxideMEMS Lab at Purdue University’s Elmore Family School of Electrical and Computer Engineering in collaboration with BAE Systems have developed an innovative resonator design that promises to make wireless communication systems faster, more efficient, and more reliable. The work was funded by DARPA under the COFFEE program. A paper detailing this research, entitled “High-performance magnetostatic wave resonators based on deep anisotropic etching of gadolinium gallium garnet substrates,” was recently published in the journal Nature Electronics.

Wireless communication, whether it’s through smartphones, satellites, or Wi-Fi, is powered by tiny, often overlooked components called resonators. These devices filter signals, ensuring only the right ones are transmitted and received.

Resonators are essential in today’s wireless technology. They play a key role in ensuring clarity and precision in transmitting data across a range of frequencies. For applications such as 5G networks, radar systems, and satellite communications, resonators must handle extremely high frequencies without sacrificing performance.

The two main challenges resonators face are balancing signal clarity, or quality factor (Q), and signal efficiency, also known as the coupling coefficient (k²). Improving one often comes at the cost of the other, creating limitations for current designs.

Acoustic waves are the vibrations we hear as sound, traveling through air, water, or solids by compressing and decompressing particles. Commercial acoustic resonators are made from materials like piezoelectric crystals, work well at lower frequencies but struggle as communication moves into higher frequency ranges.

Purdue researchers are developing next-generation technology that involves magnetic materials supporting spin waves. Unlike acoustic waves, Spin waves are ripples in the magnetic orientation of tiny spins in a magnetic material, without moving particles physically. While acoustic waves are common in everyday life (like music or speech), spin waves are crucial in advanced technologies like magnetic storage and are detected only with specialized tools.

Yttrium iron garnet (YIG), a magnetic material known for its low energy loss, has shown promise for high-frequency applications. However, manufacturing challenges have prevented YIG-based resonators from achieving the efficiency needed for modern communication systems.

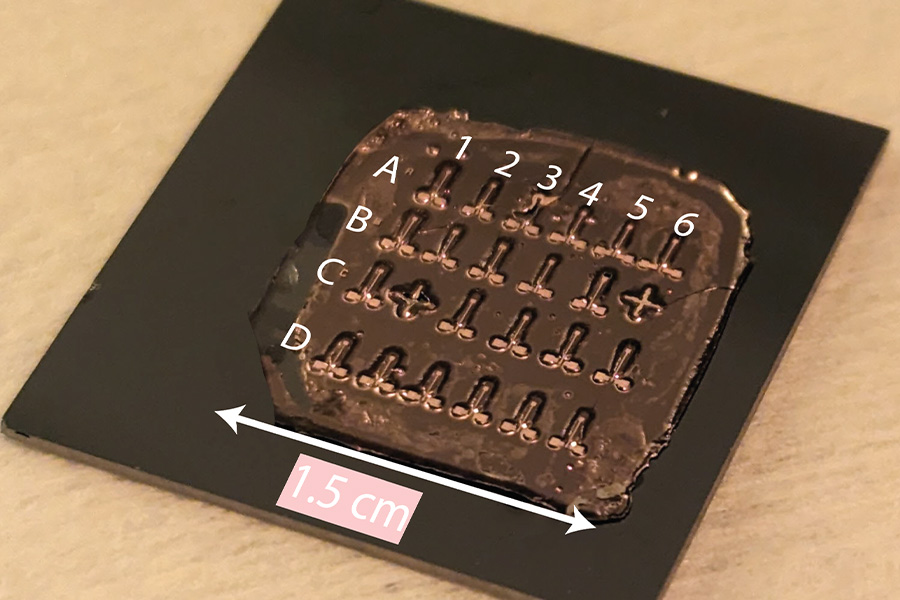

The Purdue team overcame these hurdles by creating a new "hairclip" resonator design. This innovative structure brings key electrical components closer together, dramatically improving efficiency. A groundbreaking microfabrication process allows precise shaping of the materials, multiplying the signal efficiency compared to previous designs.

Sudhanshu Tiwari is a postdoctoral researcher for Purdue’s Birck Nanotechnology Center and lead author on this paper. He says the hairclip resonator is compact, highly efficient, and performs exceptionally well in the 6–20 GHz frequency range—critical for next-generation technologies like 5G and satellite communications.

This breakthrough highlights how advanced design and microfabrication techniques can fully harness the potential of magnetostatic wave resonators. The discovery of anisotropic etching in gadolinium gallium garnet (GGG) is as transformative as the introduction of anisotropic silicon etching in the 1960s, which spurred the rapid advancement of MEMS devices like pressure sensors and accelerometers. Since yttrium iron garnet (YIG)—a highly versatile material—is typically grown on GGG, this etching technique is expected to drive innovation in fields such as radio-frequency (RF) communications, magnonics, and quantum information processing. In this paper, we demonstrate its use in enhancing resonator coupling, but its potential extends far beyond this application, promising even more exciting developments in the future.

This breakthrough highlights Purdue University’s leadership in developing cutting-edge technology. By addressing long-standing challenges in resonator performance, the team has paved the way for faster, more reliable communication systems that will shape the future of technology.

Source: High-performance magnetostatic wave resonators through deep anisotropic etching of GGG substrates