Embracing entrepreneurship in senior design

Unlike most capstone courses, senior design at the Weldon School actually begins in the sophomore and junior years—this is one of the foundational strengths of the model.

“We prepare them well for doing data-driven designs in the lower course requirements and labs,” says Jackie Linnes, assistant professor of biomedical engineering. “We teach them the design skills they need in other courses. Then they get to senior design and realize that they have been designing all along.”

Students also draft a product development proposal (PDP) in the junior year and can choose to develop that project in senior design.

Once in the senior level course, students experience the full advantage of the Weldon School senior design model: support from a diverse team of faculty and staff members, access to facilities and resources needed to fully develop their product, and mentoring from industry and clinical partners.

Purdue’s entrepreneurial focus

The Weldon School is built on a long tradition of moving innovative products and technologies to market, and this entrepreneurial spirit is nurtured in the capstone course.

Translatability begins with the identification of a real clinical need. An innovative startup strategy, called Lean LaunchPad, helps students uncover customer pain points. The experiential learning concepts of Lean LaunchPad drive students through the rigors of interviewing clinicians, patients, and manufacturers to help them better understand the customer’s needs.

It’s a reality check on the real-world marketability of their solutions, and better than the all too common scenario of coming up with a solution and then hunting for a customer.

“As engineers, it’s easy to come up with a solution to a problem. But it can be hard to come up with a solution that matters,” says Linnes.

Matthew Lynall, clinical associate professor of management from Purdue’s Krannert School of Management, lectures on topics of customer discovery and hypothesis-driven business development during the course.

“With the help of Krannert, we’re really encouraging students to be more entrepreneurially minded, thinking beyond the scope of their devices and looking at their ideas as something that could be in the marketplace,” says Hyowon “Hugh” Lee, assistant professor of biomedical engineering.

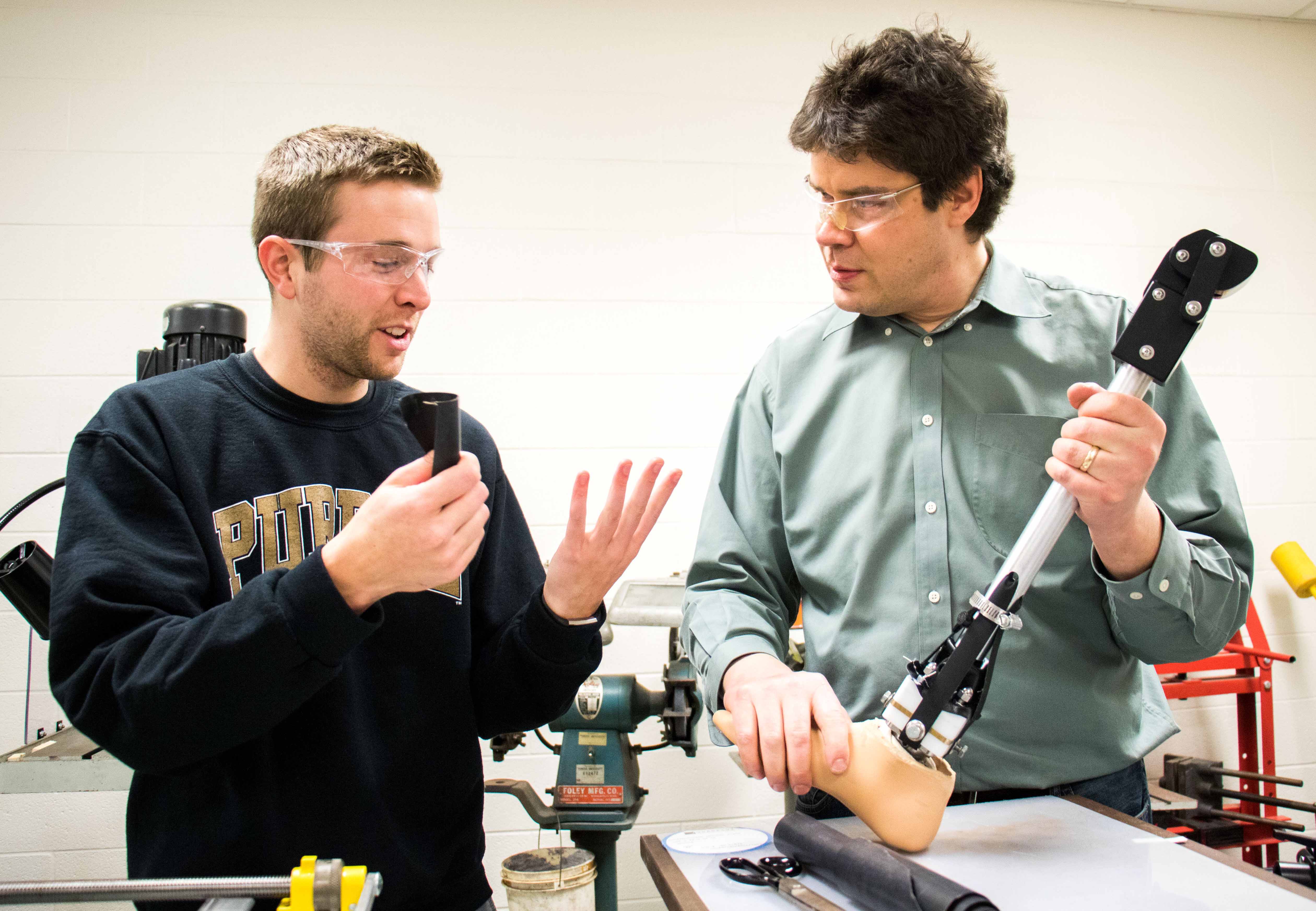

From the onset of senior design, faculty and staff members meet with the teams multiple times a week to impart theoretical and practical knowledge. Teams are also mentored by industry and clinical partners throughout the device design process to keep them on target and to strengthen and validate their solutions. Some partners have included Indiana University Health, Indianapolis Zoo, and Range of Motion Project (ROMP), a globally focused nonprofit dedicated to providing prosthetic and orthotic care to those who cannot otherwise access these services.

When students are ready to build a prototype, they have access to an uncommon suite of resources, including 3D rapid prototyping machines, a fully equipped machine shop on site, and research technical assistants and staff engineers on hand to advise and assist with equipment and production. These resources help students develop designs into working prototypes that can be tested and refined until the product is fully realized.

At the end of the course, they have an advanced functional prototype with a detailed design history file, which includes design verification and validation, that is well-situated for the next stage of clinical translation. Students can take an optional second semester of senior design to deepen their training and continue to move the product toward translation. If a student sticks with their junior year PDP and takes second-semester senior design, they will follow the development of their project for a year and a half—a rare opportunity among standard senior design models.

Cassie Parker (BS ’15), who now works at Cook Medical in Bloomington, Indiana, says the course was invaluable in preparing her for a professional career.

“As far as its ability to prepare me for industry, senior design was the best course I took because you actually get to work on the design of a large project, very similar to what you do in the real world,” Parker says.

Award-winning teams

The Weldon School capstone course has produced several award-winning senior design teams. According to Lee, roughly 25 percent of senior design teams go on to participate in local and national design and business plan competitions in the second semester of the senior year. He’s hoping that number continues to increase.

Parker and a six-person team — along with the help of Dr. Thomas Gallen, an anesthesiologist at IU Health Arnett and Dr. Jeff Ko, a veterinary anesthesiologist at the Purdue College of Veterinary Medicine — received the top undergraduate division prize of $20,000 in the 2016 Purdue Burton D. Morgan Business Plan Competition. They developed the HemoTherm, a device that monitors real-time blood oxygenation levels for hemodynamically stable and unstable patients in order to control core body temperatures.

Other recent awards by senior design teams include a $20,000 prize in the NIH NIBIB/VentureWell Design by Undergraduate Teams (DEBUT) challenge for a smart pill that diagnoses tuberculosis, as well as first place in Purdue’s Spark Challenge for StrideSmart, a smart assistive cane attachment used by elderly people to prevent falls.

Global health horizons

Senior design administrators continue to evolve the course, and have big plans for the coming years. Lee says that students can expect more hands-on opportunities for specialized training in a host of engineering skills, such as fabrication, modeling, instrumentation, signal processing, and more.

Linnes is interested in emphasizing global health and assessing needs in low-income countries.

“There is a whole new set of challenges abroad that you don’t find easily in the U.S.,” she says.

Over spring break, Linnes and a team of 17 students traveled to Ecuador for a study abroad course that is adjunct to the spring Junior Design. They connected with local patients, physicians, and the Range of Motion Project; observed previous senior design projects in action; and researched ideas for future senior design projects—particularly in the area of prosthetics.

Whether they are detecting cholera pathogens in water or creating a low-cost automatic CPR device, senior design students tackle a wide array of clinical needs. Although the Weldon School senior design model sets up students to succeed, it’s nevertheless impressive what they achieve in a relatively short amount of time.

“At the end of the course, we try to remind them that three months ago they had a piece of paper with an idea scribbled on it,” Linnes says. “Now they have a device that is tested and functioning. And they still have their entire careers ahead of them!”

If you have a project idea or would like to mentor or sponsor one of our teams, please complete the online form on our senior design website or contact us. Our students appreciate the opportunity to learn from and work with professionals in the biomedical field.

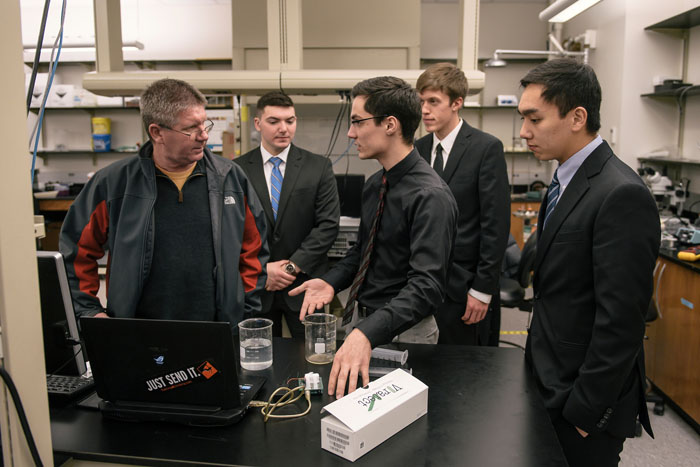

Photo captions:

Top two photos: Students explain their senior design projects to visitors after the 2016 Weldon School of Biomedical Engineering Senior Design Exposition.

A student discusses his senior design project with David McMillan, research technical assistant, in the Machine Shop.

Purdue students Tori Clift and Sahil Sanghani answer questions from judges about their business plan presentation for HemoTherm.

Weldon School students traveled to Ecuador over spring break for a study abroad course that is adjunct to the spring Junior Design. They studied processes and challenges associated with developing prosthetics and brought back ideas for senior design projects.