Kendra A. ErkPurdue University

Project Title: Electrospinning of Conducting Polymer Fibers |

|

Introduction

Electrospinning is a process by which high static voltages are used to produce ultra-fine fibers from a polymer solution. The diameters of the resulting fibers commonly range from micron to submicron lengths. Electrospun fibers have very large surface area to volume ratios, roughly one to two orders of magnitude greater than continuous thin films. These fibers are significant to applications dependent upon surface area, such as filtration systems, wound dressing, sensors, and photovoltaic cells.

Electrospinning has been successfully attempted and studied on a wide variety of polymers: polystyrene, polyethylene oxide, polymethyl methacrylate, and polyvinyl alcohol. However, little research has been completed on conducting polymers. These polymers have been studied for many decades as possible synthetic metals because they combine the chemical and mechanical properties of polymers with the electrical properties of metals. Conducting polymers are relatively easy and inexpensive to manufacture, flexible, light-weight, and chemically stable. Some applications well suited for conducting nanofibers are molecular wiring in nanostructures and nanowire chemical sensors. The goals of this project were to electrospin conducting fibers from water-soluble conducting, polymers polypyrrole and polyaniline sulfonic acid, blended with a structural polymer, polyvinyl alcohol, and to examine the effect of increased structural polymer concentrations on spinning parameters and conductivity.

Project Objectives

- Electrospin water-soluble conducting polymers and conducting/structural polymer blends

- Characterize resulting fiber morphology and processing parameter (accelerating voltage, solution concentration, tip-to-target distances) effects

- Measure and analyze resistance and resistivity values for both thin films and fibers formed from the same polymer blend

Approach

- Attempt to electrospin conducting polymers alone

- Blend conducting polymers with a structural polymer to increase spinning ability and fiber yield and determine optimal conducting-to-structural polymer blend ratio

- Use optical microscopy to obtain fiber diameters and observe structural differences between fibers, such as the formation of smooth vs. beaded fibers

- Measure the resistance and calculate the resistivity of fibers and thin films produced from the same solution

Findings

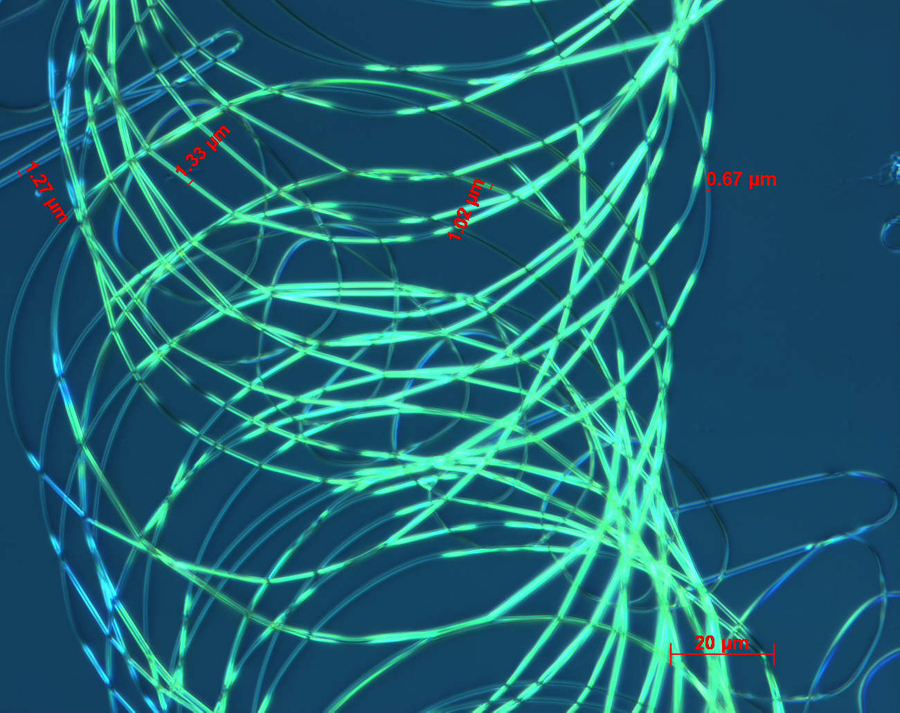

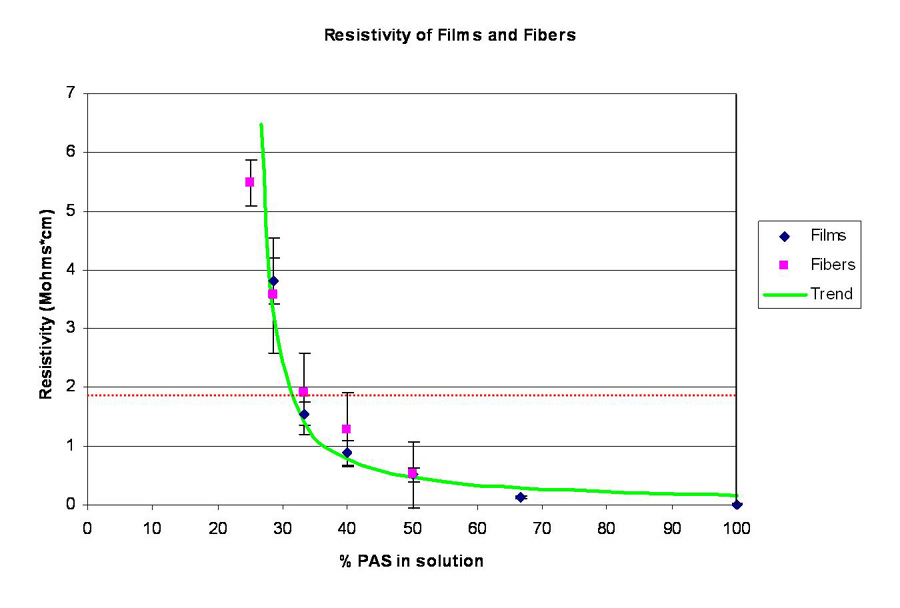

Blends of polypyrrole, polyaniline sulfonic acid, and polyvinyl alcohol were successfully electrospun to form fine fibers of micron to submicron diameters. PP/PVA blends resulted in low-yield, beaded fibers with submicron diameters. Electrospun PAS/PVA blends formed high-yield, smooth fibers with 0.6-3 µm diameters. Blends had varying ratios of PAS to PVA. In order to examine the conductive properties of PAS/PVA blends, both thin films and electrospun fibers underwent extensive resistance analysis. With increased concentrations of PVA in the films, resistivity ranged from 0.012-3.81 Mµ-cm. The percentage of PAS in the thin film solutions and the corresponding resistivities were inversely related, meaning that at lower concentrations of PAS (higher PVA concentration), films displayed higher average resistivities. This is due to the increased PVA regions creating discontinuity within the PAS regions and hindering electron mobility, essentially restricting movement of charge carriers between the conducting PAS chains. Fibers were produced with resistivities ranging from 0.511-5.49 Mµ-cm, which closely follows the same inverse trend as the film resistivity data. A silicon wafer was measured using the same procedure, resulting in a resistivity of 1.87 Mµ-cm, indicating that at low percentages of PVA (approximately below 67 wt% of the solution), the conductivities of the films and fibers exceeded that of silicon, a semiconductor.

It is worthy to note that while both fibers and films produced from the same PAS/PVA polymer blends display conductivities within the semiconducting range, the fibers have much greater surface area to volume ratios than the films. Hence, in environments where conductivity and surface area are equally significant (such as with photon-absorbing photovoltaic materials), electrospun conducting fibers have an obvious advantage over thin films.

Fig. 1. 1:1.5 PAS:PVA fibers spun at 14.97 kV, 25 cm. |

Fig. 2. Graph of film and fiber resistivities for PAS/PVA blends. |

Contact me: kaerk@purdue.edu