MSE Safety & Equipment Newsletter

February 2025

Important Upcoming Dates

- February 10-14: Purdue EHS Lab Safety Awareness Week (details below)

-

February 14: ISP Self-Audit Checklists are due (details below)

Spring ISP Inspection for ARMS and MSEE: Checklists are due Feb 14th

As part of our Integrated Safety Plan (ISP) lab certification with Purdue EHS, each year we conduct a guided “self-audit” of the safety training procedures, hazards, and hygiene of all lab spaces that MSE personnel utilize at Purdue using this Self-Audit Checklist. After our checklists are submitted, EHS staff will inspect select lab spaces in each building.

To prepare for these spring inspections, now is the time to complete the checklist and identify & fix any lingering lab safety and hygiene issues in the lab spaces where you most frequently work. The indemnification timeline is as follows:

- February 14: Deadline for Self-Audit Checklists must be submitted to the Casey Peters for review and corrections, if needed. Hard copies of the checklist and the lab master list are available outside of Prof. Erk’s office (ARMS 2315). The checklist must be signed by the Lab Supervisor and then submitted to Casey Peters by Feb. 14th by email or to his ARMS mailbox (for hardcopies).

- March 1: Self-Audit Checklists are submitted to Purdue EHS and select labs are inspected. A list of Items of Concern is created for each lab space and sent to the MSE lab supervisors for correction (abatement).

- April 15: Abatement reports are submitted to Purdue EHS for final review and certification.

The most common issues encountered during the inspections are the following:

- Unlabeled Containers: All containers need appropriate labels that indicate their contents, even “water”. In particular, waste containers should be labeled using the orange Hazardous Waste Disposal Tags and include the following information: PI name, chemical names (written out; no acronyms or chemical formulas), volume percents, and an indication of hazards at bottom of label.

- Personal Protective Equipment (PPE): It is important that all PPE be kept clean and properly maintained. If lab coats are intended to be reused, do not store them atop one another, on seats/chairs, or in any other manner where cross contamination may occur.

- Power Strips and Extension cords: Extension cords should not be used as permanent wiring. Muli-outlet “power strips” also need to have 15-amp over-current protection (typically, these are the power strips with an “on/off” button). Household-use extension cords are not permitted due to the potential for overload.

- Clutter and Excess Cardboard Boxes: Workspaces should be free from excess clutter (e.g., 1000 samples on a benchtop, 10+ waste bottles in the fume hood) as well as too many boxes stored on top of cabinets and empty/old boxes stacked in the corner. Remember, lab users will typically need to breakdown and take boxes to the dumpsters near the loading dock; janitors will not do this for you.

Purdue EHS Lab Safety Awareness Week

Purdue EHS is partnering with the Campus Safety, Health, and Environmental Management Association in recognizing Lab Safety Awareness Week, from February 10-14, 2025. During this week (but really, during all 52 weeks of the year), campus researchers and laboratory personnel are encouraged to prioritize and foster a strong safety culture in their daily activities.

To support Lab Safety Awareness Week, those working in labs are encouraged to participate in EHS’s first-ever Fume Hood Clean-Out photo challenge. To participate, lab personnel are encouraged to submit photos of their fume hood prior to and after cleaning. The first three labs to submit and meet all requirements will win a pizza party! Photos should be submitted together through this online form before the end of the week. Only one submission per lab will be accepted.

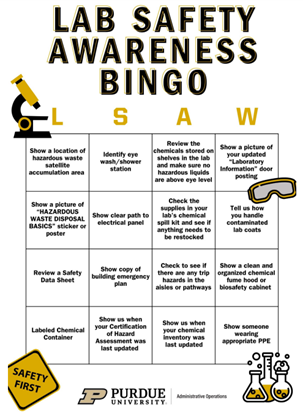

Additionally, all lab personnel are invited to participate in the Lab Safety Bingo Challenge. The first 25 participants to complete a bingo will win a free T-shirt! Download your bingo card here and submit your completed entry via email to researchsafety@purdue.edu.

PPE Reminder: BYO Safety Glasses

Just a reminder that all MSE personnel are responsible for securing and maintaining their own required personal protective equipment (PPE), which typically includes safety (impact-resistant) glasses and sometimes a laboratory coat. Previously, safety glasses were available for students to borrow temporarily from the MSE Main Office. But going forward, there will no longer be any safety glasses available for this purpose. So plan ahead and be sure to bring your safety glasses to lab!

Safety Best Practice: Reporting Near-Miss Incidents

A near miss—sometimes called a close call or a good catch—is an unsafe event that falls short of causing significant injuries, property damage, or release of hazardous materials into the environment. For example, a researcher may have almost burned their hand on an unmarked extension from a tube furnace but recognized the hazard at the last minute. It is important to report these events because they can lead to interventions that may prevent major accidents and injuries in the future.

Reporting: There are three ways to report near-misses within MSE: (1) talk to Casey Peters (ARMS 2200-1), (2) email mse-safety@purdue.edu with a description of the near-miss event; and (3) scan any QR code on the lab doors and fill out the short form. Academic studies have shown that safety cultures in which near-miss reporting is encouraged will have a lower likelihood of major accidents. For more information, check out this Chemical & Engineering News article.

What to do if you get injured at Purdue?

Unfortunately, accidents and injuries happen, typically when you least expect it – so let’s review what to do…

- First, don’t panic.

- Second, call 911 in the event of a major accident (all fires, electrical hazards, and large chemical spills) or major injury (defined below).

- Next, secure the area and take immediate action if needed (e.g., use the safety shower or eye wash, administer basic first aid).

- Then, tell someone – the lab supervisor, a MSE staff member, your lab instructor.

Major injuries may include the following: chest pain, difficulty breathing, head injuries, fractures, dislocations, uncontrolled bleeding, neck or spine injuries, severe back pain, severe eye injuries, chemical burns. For any of these, call 911 for ambulance transport to a local hospital.

Minor injuries typically include minor cuts, bruises, abrasions, and punctures; minor burns and rashes; dust or dirt in eyes; sprains, strains, and repetitive motion injuries. To treat minor injuries, your status at Purdue dictates where you should go and is detailed here. In brief, anyone who is paid by Purdue (faculty, staff, paid researchers at any level) should travel to Unity’s ROCC or Franciscan’s WorkingWell Lafayette clinic while un-paid students should go to PUSH. For immediate treatment of minor injuries after 5 pm and on weekends, Purdue personnel should go to an urgent care facility, either Franciscan ExpressCare West Lafayette or Unity Immediate Care.

All injuries, regardless of how slight, must be reported to your supervisor within 24 hours. The first reporting step is to click “Report an Injury” on EHS’s homepage (link). The webpage will then direct paid personnel to complete a First Report of Injury (FROI) form while unpaid personnel (students & visitors) will be directed to a form through the Office of Risk Management (link).

And let’s not forget about personal health and safety...

The end of the semester brings excitement for winter break with the stress of more deadlines (and even more holiday parties). Here is a collection of links which may be helpful:

- Purdue’s safe walk program (24/7 escorts to/from campus buildings): call 765-494-SAFE (7233)

- Purdue links to report a safety concern or incident, including “Student of Concern” reporting

- Office of Graduate Assistance, including Ombuds

- Purdue’s Mental & Emotional Health services

- Purdue University Student Health (PUSH) service, including CAPS

Equipment & Lab Access Reminders

If you encounter a piece of broken equipment, or have any questions about a specific piece of equipment, you should contact a member of the MSE Technical Staff:

- For sample prep (i.e., saws, grinding wheels) equipment and mechanical testing equipment: Tim VanMeter

- For characterization equipment and iLab: Sam Schmidt

Important Links and Contact Information

- For MSE safety questions, concerns, and lab access issues: mse-safety@purdue.edu or speak directly to MSE Safety Officer Casey Peters (ARMS 2200-1)

- Equipment/Safety/Consumables Reporting Form (QR Code on MSE lab doors)

- Purdue’s Emergency Procedures Guide

- Purdue’s Office of Environmental Health and Safety (EHS), formerly known as REM

- Purdue Police Non-Emergency: (765) 494-8221

- Purdue Fire Non-Emergency: (765) 494-6919

- Purdue REM Non-Emergency: (765) 494-6371

- For all emergencies, dial 911.

Thanks for reading everyone!

Prof. Erk, Casey Peters, and the MSE Safety Committee