Mechanical Testing of Fuel Cell Materials after Thermal Shock Veronica Valdez

University of Texas at El Paso

Professor Trice

Introduction

There is a need to cease dependence on depleting fossil fuels due to escalating energy demands and environmental concerns. Solid oxide fuel cells are electrochemical energy conversion devices that use a hard ceramic electrolyte and operate up to temperatures of 1000oC. Solid Oxide Fuel Cells encompass many favorable characteristics such as energy efficiency, fuel flexibility, inexpensive catalysts and environmental convenience.For my research, the substrate material that was evaluated for the Solid Oxide Fuel Cells was a two phase magnesia-spinel composite. Rods of this composite were made through extrusion techniques and then were sintered. The rods were approximately 52 mm long and 1.9mm in radius.

Research Objectives

Evaluate MgAl2O4 as a substrate material for Solid Oxide Fuel CellsExperimental Approach

To characterize the magnesia-spinel composite different methods were used. Physical characterization evaluations were performed to find volume and porosity using Archimedes density. X-ray Diffraction Analysis between 20o – 80o was used to confirm MgAl2O4 phases and structure.To determine the effects of thermal shock on MgAl2o4 rods were exposed to temperatures of 350oC, 450oC, 550oC, 750oC, 850oC, 950oC, and 1050oC for one hour and then immediately quenched in water at ambient temperature as the cooling medium.

To determine the flexural stress that MgAl 2 O 4 can withstand after the thermal shock quench a four point flexure test was used using a four point fully articulating fixture.

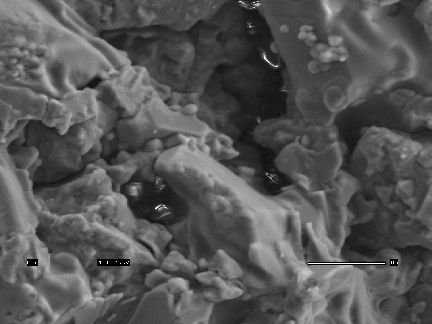

To analyze the fracture surfaces the Scanning Electron Microscope was utilized. Weibull Analysis was done by using 30 room temperature sample results after flexure testing.

Results

MgAl2O4/MgO composite ceramic exhibits 25% porosity and considerable strength retention after thermal shock quench. Thermal Shock introduced surface cracks due to tension and reduced strength.Weibull Analysis reveals a high Weibull modulus thus a 99.9% Probability of Failure at 45.9 MPa,

50% Probability of Failure at 38.9 MPa,

20% Probability of Failure at 35.9 MPa,

0.1% Probability of Failure at 24.3 MPa.

Polished Cross Section of MgAl2O4/MgO