Dena RafikImperial College London

Project Title: Deposition of Lithium Fluoride Thin Films

|

|

Introduction

Nanotechnology is a rapidly developing field, which deals with small objects to the order of less than a micron big. It involves rearranging atoms in materials to obtain properties that are important in appliances to improve its efficiency. Thin Films are a major part of the nano-industry and a great deal of research has been invested in them. When dealing with thin films and its properties it is important to understand the morphology and structure of the film. A high level of understanding of how the films are developed is a necessity when trying to obtain particular structures in the film. Electronic appliances are rapidly decreasing in size which is due to the components size decreasing. For this project, transistors are the component of interest. Currently they are connected in circuits by thin wires. The problem with this is that they are difficult to manufacture and they may conduct isotropically which reduces efficiency of component.Project Objective

The main objective of the project is to replace the connector with a bulk material that conducts anistropically. The material to be researched is Lithium Fluoride which is a ceramic material with a relatively high band gap of 14 eV. The aim is to grow columnar grains and dope the material through the triple junction. The triple junction is where three grain boundaries meet and has high rate of diffusion especially at low temperatures. Doping the material will produce an array of “nano” wires parallel to each other and as lithium fluoride is a non-conducting ceramic the doped material will conduct anistropically.Approach

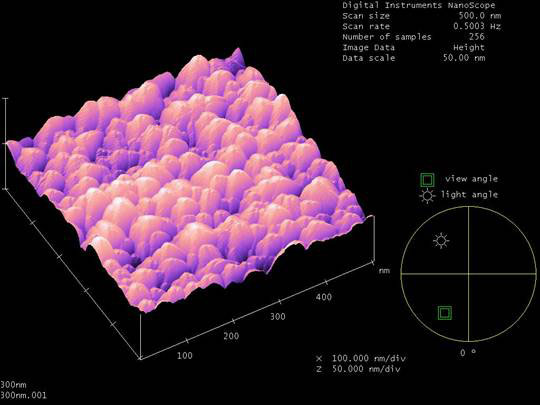

- The project was approached by initially growing thick films of Lithium Fluoride of 100 – 300nm. They were grown by Physical Vapor Deposition (PVD) which involves evaporating Lithium Fluoride powder on to a substrate in vacuum conditions. These films were analysed inorder to become familiar with equipment then we deposited thinner films of 20nm – 100nm

- Films were initially analysed using optical microscope and Atomic Force Microscope (AFM)

- Grain size comparisons were made between the thicknesses of the film from the AFM images.

- Created and installed a heater in to the vacuum chamber to heat the substrate before deposition and see if that has an effect on structure. The purpose of this is to relieve thermal stress during cooling of film.

- Samples were also annealed to relieve the thermal stresses that were built up during deposition on to a cold substrate.

- Samples of similar thickness, but different treatment were analysed and compared for grain size, porosity and thickness.

- Research in to texturing of films was carried out using X- Ray Diffraction (XRD) and Area detector

Findings

The following results were obtained:- The AFM images show as thickness increases grain size increases. Also the results show equiaxed grain microstructure where the grain size is proportional to film thickness. This reconciles with the grain growth theory.

- From XRD data and Area detector there was very little texturing apparent, which was not significant enough to draw any strong conclusions.

- There is significant porosity in the films. Annealing the samples have significantly high porosity (approx. 50%) where as depositing on a heated substrate has porosity by aprox. 15%.

- Depositing film on to a heated substrate has lower porosity because the grains grow at a slower rate. This technique of deposition gives thickness values that closest match the thickness monitor values.

- Annealing increases mean thickness and grain size of film. In addition, annealing may cause a hillocked microstructure.

- Depositing film on heated substrate achieves a more ordered equiaxed grain structure

- Annealing films deposited on silica substrate may cause severe tensile stress and cause film to crack

Figure 1: 3D AFM Image of 300nm LiF (500nmx500nm) |

Figure 2: Substrate Heater (Alumina plate with Nichrome wire) |