Purdue BME Researchers Create Faster, More Precise Gelatin-Norbornene for Advanced Hydrogels and Bioprinting

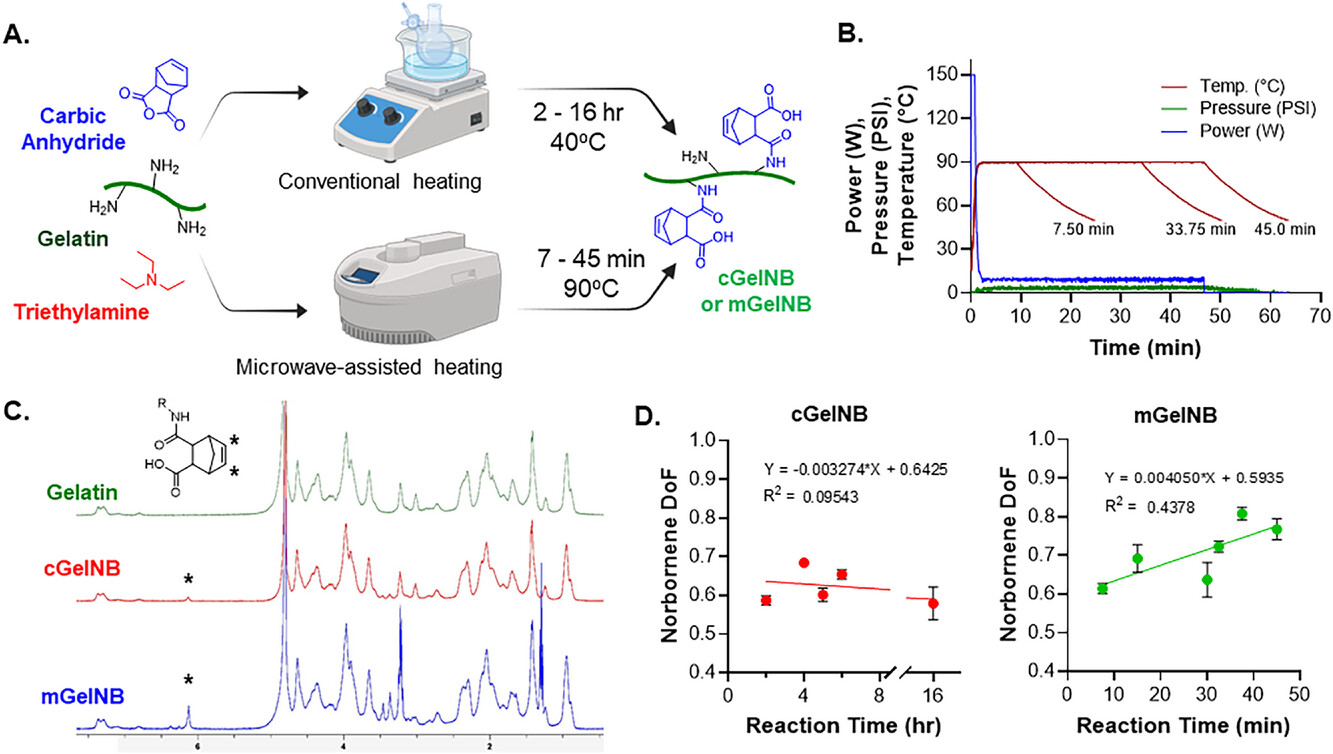

GelNB is a popular macromer for step-growth thiol-norbornene photopolymerization because it combines the precision of click chemistry with the biological relevance of gelatin, supporting cell adhesion, protease-mediated remodeling and high cytocompatibility. However, conventional GelNB synthesis requires long heating steps and provides limited control over modification levels.

The Purdue team’s method changes that. By adapting the reaction to a microwave reactor, they reduced the synthesis time from hours to just minutes and achieved highly reproducible norbornene conjugation between 60% and 90%. This enhanced precision allows researchers to fine-tune the resulting hydrogel’s mechanical properties, spanning shear moduli from 60 to 15,000 Pa.

Microwave heating also increases the water solubility of GelNB at room temperature—an important improvement for digital light processing (DLP) 3D bioprinting, which often requires heating materials above physiological temperatures. With this new method, GelNB can be printed more easily and with greater temperature stability.

The researchers demonstrated that hydrogels formed from microwave-synthesized GelNB (mGelNB) remain highly cytocompatible. When encapsulating human umbilical vein endothelial cells (HUVECs), the mGelNB hydrogels supported greater vascular junction formation and vessel length density compared to traditionally synthesized GelNB.

This innovation simplifies the workflow for producing biologically active hydrogels and expands their utility across tissue engineering, disease modeling, drug delivery, and biofabrication. By bringing speed, consistency, and improved performance to GelNB synthesis, Purdue’s work empowers researchers with a more accessible and powerful platform for designing next-generation biomaterials.