Simple stickers may save lives of heart patients, athletes and lower medical costs for families

Purdue University researchers have advanced a sticker solution moving it several steps closer to reality. The research was recently published in ACS Advanced Materials and Interfaces. A YouTube video is available at http://bit.ly/EPED-Purdue.

For the first time, we have created wearable electronic devices that someone can easily attach to their skin and are made out of paper to lower the cost of personalized medicine,” said Ramses Martinez, a Purdue assistant professor of industrial engineering and biomedical engineering, who led the research team.

Their technology aligns with Purdue's Giant Leaps celebration, acknowledging the university’s global advancements made in health as part of Purdue’s 150th anniversary. This is one of the four themes of the yearlong celebration’s Ideas Festival, designed to showcase Purdue as an intellectual center solving real-world issues.

The “smart stickers” are made of cellulose, which is both biocompatible and breathable. They can be used to monitor physical activity and alert a wearer about possible health risks in real time.

Health professionals could use the Purdue stickers as implantable sensors to monitor the sleep of patients because they conform to internal organs without causing any adverse reactions. Athletes could also use the technology to monitor their health while exercising and swimming.

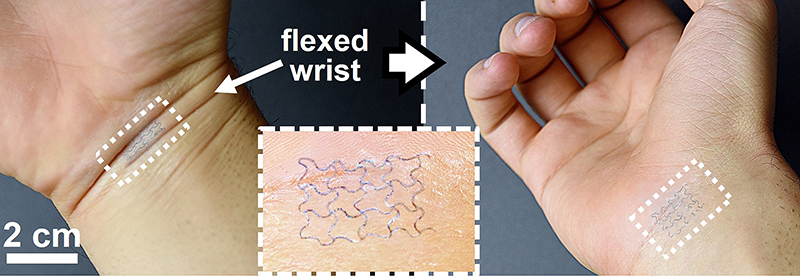

These stickers are patterned in serpentine shapes to make the devices as thin and stretchable as skin, making them imperceptible for the wearer.

Since paper degrades fast when it gets wet and human skin is prone to be covered in sweat, these stickers were coated with molecules that repel water, oil, dust and bacteria. Each sticker costs about a nickel to produce and can be made using printing and manufacturing technologies similar to those used to print books at high speed.

“The low cost of these wearable devices and their compatibility with large-scale manufacturing techniques will enable the quick adoption of these new fully disposable, wearable sensors in a variety of health care applications requiring single-use diagnostic systems,” Martinez said.

The technology is patented through the Purdue Office of Technology Commercialization. They are continuing to look for partners to test and commercialize their technology.

Source: Simple stickers may save lives of heart patients, athletes and lower medical costs for families

ABSTRACT

Wearable and Implantable Epidermal Paper-Based Electronics

Ramses Martinez

Purdue University, West Lafayette, IN, USA

DOI: 10.1021/acsami.8b11020

Traditional manufacturing methods and materials used to fabricate epidermal electronics for physiological monitoring, transdermal stimulation, and therapeutics are complex and expensive, preventing their adoption as single-use medical devices. This work describes the fabrication of epidermal, paper-based electronic devices (EPEDs) for wearable and implantable applications by combining the spray-based deposition of silanizing agents, highly conductive nanoparticles, and encapsulating polymers with laser micromachining. EPEDs are inexpensive, stretchable, easy to apply, and disposable by burning. The omniphobic character and fibrous structure of EPEDs make them breathable, mechanically stable upon stretching, and facilitate their use as electrophysiological sensors to record electrocardiograms, electromyograms, and electrooculograms, even under water. EPEDs can also be used to provide thermotherapeutic treatments to joints, map temperature spatially, and as wirelessly powered implantable devices for stimulation and therapeutics. This work makes epidermal electronic devices accessible to high-throughput manufacturing technologies and will enable the fabrication of a variety of wearable medical devices at a low cost.