Designing 3D Conical-Shaped Lithium-Ion Microelectrodes

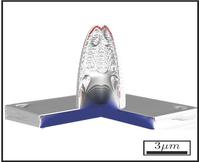

Stress distribution for high aspect ratio structure, at the end of a 1C discharge sequence. Simulation shows that lithium intercalation and diffusion induces a non- uniform expansion of the conical structure, which leads to a compressive state of stress on the back contact, and a weak tensile state of stress at the electrochemically active tip.

Purdue (Daw Gen Lim, Ding-Wen (Tony) Chung, and R. Edwin García) and Karlsruhe Institute of Technology (Robert Kohler, Johannes Proell, Christopher Scherr, and Wilhelm Pfleging) researchers have demonstrated geometries that maximize power density and suppress chemomechanical stresses.

Senior undergraduate student, Daw Gen Lim, Purdue MSE BMSE, 2014 (R. Edwin García, advisor), has proposed a set of device fabrication guidelines to enable the optimization of 3D microbatteries. Architecture parameters (e.g., aspect ratio and density of cones) controlling its performance (e.g., power and energy density) have been proposed and used to rationalize emerging state-of-the-art 3D designs. The effect of the architecture and C-rate on its chemomechanical reliability is also analyzed, enabling the realization of fatigue-resistant energy storage devices.

Related Link: http://jes.ecsdl.org/content/161/3/A302.abstract