"MeCast" team wins Dassault Systemes Additive Manufacturing Hackathon with personalized cast

Traditional casts are often designed with plaster of paris or fiberglass material, which can be heavy, cumbersome, and water absorbent. They can impede healing if poorly designed, reduce skin health, and cause itchiness.

Traditional casts are often designed with plaster of paris or fiberglass material, which can be heavy, cumbersome, and water absorbent. They can impede healing if poorly designed, reduce skin health, and cause itchiness.

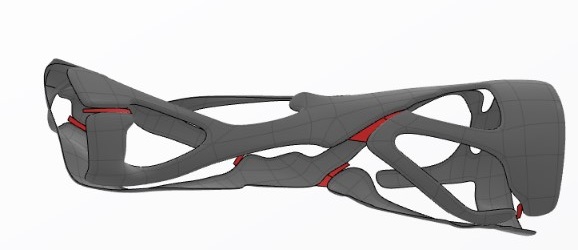

"MeCast," a personalized cast uniquely designed for its user, overcomes the difficulties of the traditional cast. It is an organic design based on a 3D scanned model of the fracture.Using simulations of the bone, muscle and cast assembly for different load cases, the cast is designed to minimize the relative motion between the fractured bones. A topology optimization algorithm (Tosca) is run to minimize the weight by removing excess material. This material removal exposes the skin near affected region to air and improves skin health.

The Additive Manufacturing Symposium and Hackathon was held in Chicago, Illinois, May 15-17.

The images above represent the “MeCast,” a personalized orthopedic cast for fractures.