MICROSTRUCTURES OF SPRAYED ZIRCONIA THERMAL BARRIER COATINGS

Prof. Alex King

School of Materials Engineering

|

|

High-resolution cross-section transmission electron microscope image of the interface between a substrate and a solidified zirconia particle formed by plasma spraying. |

One way of allowing a superalloy gas turbine blade to operate at higher temperatures is to apply a thermal barrier coating - essentially a layer of insulation that keeps the surface of the metal cooler. Thermal barrier coatings must be able to withstand higher temperatures than the blade itself can, but they do not have to have the same strength, because most of the structural integrity is provided by the metal blade itself. The coating must, however, adhere reliably to the blade. This requires appropriate mechanical properties, as measured by Professor Trice, and the coatings must be free of dangerous flaws.

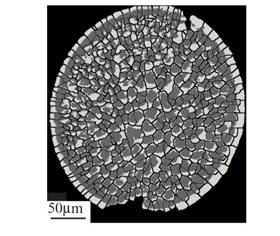

We have used cross-sectional transmission electron microscopy to assess the microstructures of plasma-sprayed zirconia coatings on metal substrates. The microstructures show evidence of substrate melting, columnar grain growth, fluid flow during particle solidification, and a number of other microscopic effects.

A novel scanning electron microscope technique has been developed to reveal the extent of cracking between a zirconia layer and its substrate, without destroying the specimen. This reveals that shrinkage cracks formed though the thickness of the zirconia layers during solidification also nucleate lateral cracks along the interface between the coating and the substrate. The extent of these lateral cracks can be measured reliably and non-destructively, as a function of process variables and service duty cycles.

Processed scanning electron microscope image of a solidified zirconia droplet on stainless steel. The dark lines are shrinkage cracks, the gray areas are well-adhered and the light areas are not adhered to the substrate. The relationship between the shrinkage cracks and the delamination can be deduced from images of this type.

Publications

T. Chraska and A.H. King: Interfaces in Rapidly Solidified Zirconia-Yttria, Mat. Sci. For. 294-296 (1999) 779-784.

T. Chraska and A.H. King: Growth of columnar grains during zirconia-yttria splat solidification, J. Mats. Sci. Letts. 18 (1999) 1517-1519.

T. Chraska and A.H. King: TEM study of rapid solidification of plasma sprayed YSZ - part I. First splat solidification, Thin Solid Films (in press).

T. Chraska and A.H. King: TEM study of rapid solidification of plasma sprayed YSZ - part II. Interfaces and subsequent splat solidification, Thin Solid Films (in press).

S. Rangarajan and A.H. King: Nondestructive evaluation of delamination in ceramic thin films on metal substrates, by scanning electron microscopy, Thin Solid Films (in press).