Purdue team makes final push to win FAA Smart Airport Challenge

When Eric Eagon and Quinn Joyce started researching ways to approach the Federal Aviation Administration’s “Smart Airport Student Competition,” they were disheartened to learn how physically impaired travelers were treated in airports, how difficult it was to navigate aisle chairs and how uncomfortable the experience can be.

The problem begged for a solution, one that provided access to efficient transportation in a wheelchair and one that positively impacted disabled travelers and their sense of pride at being able to maneuver through airports without personal assistance.

A solution that met the criteria of the FAA Challenge, too, and demonstrated innovative thinking, focused on improving efficiency and effectiveness of smart technology in and around the airport environment and enhanced the overall travel experience.

The “Wheels-Up Solution,” a smart wheelchair and compatible management system that assists physically impaired travelers in the airport terminal and beyond, was developed by a team of Purdue University students, primarily in the School of Aeronautics and Astronautics (AAE).

It was a solution that, ultimately, impressed the FAA.

The team was selected as one of three finalists for the national competition. The winner will be announced in early December — and win $25,000.

“The most unique thing is it’s an all-in-one-wheelchair designed for a passenger to get from car to airplane seat, navigating the whole airport, jet bridge and boarding the plane, that was the idea,” said one of the team’s co-leads Eagon, a master’s student in AAE. “No concept currently has done that. They all include transfers from seat to seat. It seems like it’s definitely an issue, which we’ve learned through surveys and general research.”

The ultimate prize would be sweet, but the process itself actually has been its own unique reward. It has included a provisional patent, creation of multiple independent study courses in AAE, a crash course in business development and acumen, and gaining practical experience beyond expectations.

And more.

“I attended a conference recently and one of the people who was speaking said that they’re not disabled, they’re disabled in this world. We don’t provide the means for them not to be disabled,” said the team’s other co-lead Joyce, who will receive his Bachelor of Science from AAE in December.

“Honestly, that’s what drove me (in this project), after finding all the (information).”

Process starts

Eagon and Joyce first learned about the Smart Airport Challenge in September 2019 with the rest of the AAE undergraduate student body — when they saw the email from William Crossley, the J. William Uhrig and Anastasia Vournas Head of Aeronautics and Astronautics.

The FAA said it was using the competition, managed by the National Institute of Aerospace, to stimulate and advance innovation in aviation research; promote the development of a robust aviation workforce to support a growing and evolving aerospace system; develop a pipeline to fill current and projected shortages via partnerships with academia and industry; and drive a passion for aviation in today’s youth of all ages and backgrounds. The idea was to incentivize university students to think creatively in developing solutions to transportation technology challenges while addressing the human factors of the traveler’s experience and to share those innovations with the broader community.

Eagon was intrigued because it invited a very broad design competition, so he knew there were several angles to attack it. Joyce had done a Co-Op with American Airlines, so he found the challenge appealing because he could pull knowledge from that experience.

By October, Eagon and Joyce had assembled a team to tackle the challenge. As many as 10 students were involved at different points in the project, but seven are listed on the final report: Eagon and Joyce, along with AAE students Austin Barrow, Dylan Kerr, James Pannullo and Xingmei Zhu and Department of Computer Science student Brendan Kerr. Dengfeng Sun, an associate professor in AAE, was assigned as academic mentor, and AAE alumnus Jeff Tyrcha with Ceros Solutions Incorporated was industry mentor. Michele Erwin, president for All Wheels Up, an organization that advocates for wheelchair accessible air travel, also was a resource for the team.

It took several meetings — and plenty of research on possible topics — before the team narrowed its idea for the competition. One thing that stood out during the research for the project was materials focusing on people with physical disabilities and accessibility in the airport.

The team discovered a report that said nearly 31 million people had trouble walking or climbing stairs or used a wheelchair, cane, crutches or a walker in 2012 and used that as a reference for disability today. About two-thirds of Americans over 65 requiring some kind of assistance in a daily routine and with that population expected to double in the next 40 years, there will be an even greater need to address mobility issues.

Airlines and airports have lacked the ability or willingness to fund more valid solutions to the problem, the team wrote in its final report, and the team’s solution to create a new wheelchair system addressed not only the customer experience side of the problem but the operational side as well. The idea represents a chance for the FAA to “step up, take the lead and solve a great challenge for those among us who are least able to get around,” the report said.

“Working at American, it became apparent that there were some operational costs associated with transporting disabled passengers that we thought we could entice them with a new device as well. So we thought it would be good for everybody, a win for everybody,” Joyce said.

Initial research and a survey influenced designs and helped the team solidify an understanding of the problem and its current solutions. By January 2020, each individual on the team shifted beyond research to being assigned specific tasks and areas, some working on physical design and others on digital design or risk analysis.

Joyce said most of the team spent their winter break writing the first proposal, which made the news that came in February worth it: The group was selected as one of three finalists, along with teams from University of North Dakota and University of Texas at Arlington.

“It was awesome,” Joyce said. “I called Eric immediately and I was just ecstatic. I was like, ‘Dude, we made it!’ For 10 minutes, we were just in disbelief. Three teams out of the entire nation, and we had been chosen. Then our industry partner, Jeff, was arguably more excited that we’d made it. He called the both of us and was screaming in his office. So that was exciting, too.”

Eagon said it was “definitely rewarding” to be selected as a finalist, but the work wasn’t done. Along with the finalist announcement from the FAA Challenge Steering Committee came feedback from those FAA subject-matter experts. Some of the judges said the Purdue team’s solution was “very unique and creative,” “an excellent proposal,” a “well thought-out and novel approach.”

But there also were suggestions on how to improve the proposal and questions looking for more specificity in some areas, including to work on cost and security information.

“We were on to our next gear,” Eagon said. “We knew we had to get a lot more done in the coming months.”

In the midst

Considering the amount of work needed for the project, Eagon and Joyce initiated AAE497 courses for independent study or small group research projects. In Spring 2020, they had “Accessibility in Airports,” research that continued with “Accessibility in Airports II” in the summer and into this fall with “Accessibility in Airports III.”

This fall offered another course for the autonomous aspect of the design, AAE490 “Computer Vision in Autonomous Vehicles,” and AAE students were tasked with creating robust code to process static images and videos using Python.

The fall coincided with the team starting prototyping and testing, as well.

It wasn’t an easy road.

The wheelchair took extensive development and testing with input from every team member. The criteria used to decide the final wheelchair design included maneuverability, compactibility, comfortability, structural stability, cost, weight and autonomy capabilities. The final design focused on all of the criteria but specialized in a certain few.

“The chair has different technologies that were made so it could navigate an airplane aisle. That was the main challenge. That was the main thing that hasn’t really been done,” Eagon said. “There are autonomous wheelchairs out there, and they’ve come a long way. But our design picks you up, fully autonomous. In order to unlock it, you scan your passport or boarding pass. It will take you to where you want to go. It has a little GPS nav screen as part of the chair. It would be able to take you through security, to your gate and show you what’s around the airport, so if you wanted food or to go to the bathroom, you choose that and it will take you there. Once you’re at your gate, it will wait it out until boarding starts and take you down the alleyway. It would compress as you’re on it. You’d still need the help of the flight attendants (to get into the seat), but the main thing is you wouldn’t need what these airlines normally do, which is a third-party transporter who would be pushing you around and transporting you from chair to chair.”

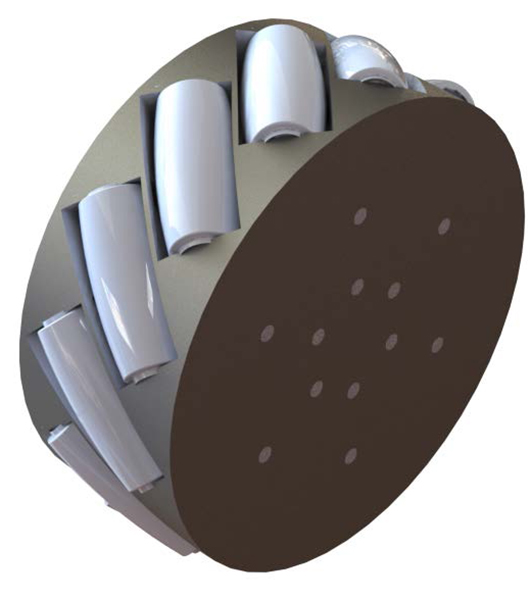

The most important aspect of the design — the one that separates the team’s concept from any current design — is the ability to manipulate the width of the wheelchair to allow direct access to the airplane. The team’s design can manipulate its standard 23-inch wheelbase to a 15-inch wheelbase that is able to maneuver any commercial airplane aisle by using a split chassis connected by two load-bearing linear slides and one electrically powered scissor jack.

To make sure the split chassis design was structurally stable, the team surrounded the chassis interior with a shell made of KYDEX plexiglass, the same plastic used in aircraft pull-down trays.

Designing a comfortable chair was an important requirement, too, considering passengers could be spending long periods of time sitting in it. But that aspect proved even more challenging with a chair that downsizes. When the chair is expanded, there is an 8-9-inch gap between the split chassis.

The team came up with a design that covers the gap and maintains support throughout its different configurations with a section of compressible hexacell support material. The material maintains its strength and rigidity under the vertical load of the passenger even when it expands horizontally and can compress laterally to less than an inch.

“There’s a special technology that’s out there right now, a way of creating a lattice structure out of some type of flexible material that will compress down to like something ridiculous, like 5 percent,” Joyce said. “So we took the design of that and incorporated it with a new material. We essentially just chose rubber at this point and we took the design to fill the gap between our two chassis pieces.”

Another design feat the team is proud of: Eagon’s idea to use mecanum wheels. The wheels allow for zero-degree turns and lateral movement, so the wheelchair can navigate any tight turns in an airport or an airplane. It’s a technology used in robotics but not in commercial products.

“It was nice having different knowledge and different technologies to put in because we needed those two things in order to make the chair work,” Joyce said.

The final push

The technical report was due on Nov. 1, but that didn’t mean the work was done.

With an oral presentation looming Nov. 19, the team spent a furious three weeks finalizing three demonstrations to show the Steering Committee. They created an augmented reality video. For the autonomous side demonstration, they built a physical prototype, as well, to showcase in a controlled environment. They also developed an animation to show how the wheelchair will fold and compact.

On Nov. 30, all three teams will have their presentations livestreamed through a public WebEx event. (Purdue’s presentation is at 1 p.m.) Each team’s presentation will be followed by a live Q&A with the judges, and the public can ask questions in the WebEx chat.

Proposals will be evaluated based on technical merit (40 percent), practicality (30 percent), impact (20 percent) and originality (10 percent) by the Steering Committee.

Eagon and Joyce said they think Purdue’s project is good enough to win.

“WheelsUp” will require less dependence on wheelchair staff and other passengers to operate the wheelchair manually because of its autonomous components, allow for a more comfortable experience for the passenger and provide quicker boarding and deplaning transition times.

“There’s one solution that’s very similar to ours that’s already on the market, and it has gained a lot of interest, especially with the advent of COVID because the autonomous tech is very helpful when you’re trying to transport people and not have people on the same buggy,” Joyce said. “We know the FAA is really eyeing some of these technologies for helping disabled passengers because it was one of the main things they were tasked with doing.”

Even without a first-place prize, the experience still may be worth it.

When the team geared up to give its first presentation to the FAA group in May, Eagon and Joyce were concerned about intellectual property. So they reached out to Purdue’s Office of Technology Commercialization and had meetings with a business manager and patent lawyer. Eagon and Joyce simply wanted advice about how to go about presenting the idea while keeping it close to the vest. At that point, OTC suggested patenting the idea. Eagon and Joyce couldn’t quite believe it. They thought their idea was good but that unique?

“They did. They took it and filed for a provisional patent in April, so that’s outstanding with the U.S. Patent Office,” Joyce said.

Eagon and Joyce have found they’ve draw upon lessons learned in AAE coursework for many pieces of the life cycle of the project — like general design practices or finite element analysis in a 352 lab or design of systems in AAE 551. But, ultimately, neither expected to have a comprehensive experience like this, mixing business with design, build, test elements.

Eagon, who received his bachelor’s from AAE in May 2020, said when he’s talked to companies at job fairs, “it almost feels like I’m making stuff up” because of the scope and scale of the project.

Joyce still shakes his head at all the work.

“It’s turned into a big project. We feel like we’ve started a business, almost,” he said. “You just have so many things. We created classes, got a patent, made it to the final three. It’s like, ‘What?’

“It’s been quite the ride. It still is.”