AAE machinist Jerry Hahn retiring after 20 years at Purdue

The standard-bearer of Purdue AAE’s machine shop is retiring. Jerry Hahn, who has served the School of Aeronautics and Astronautics for 20 years, will leave big shoes to fill when he departs at the end of December 2022.

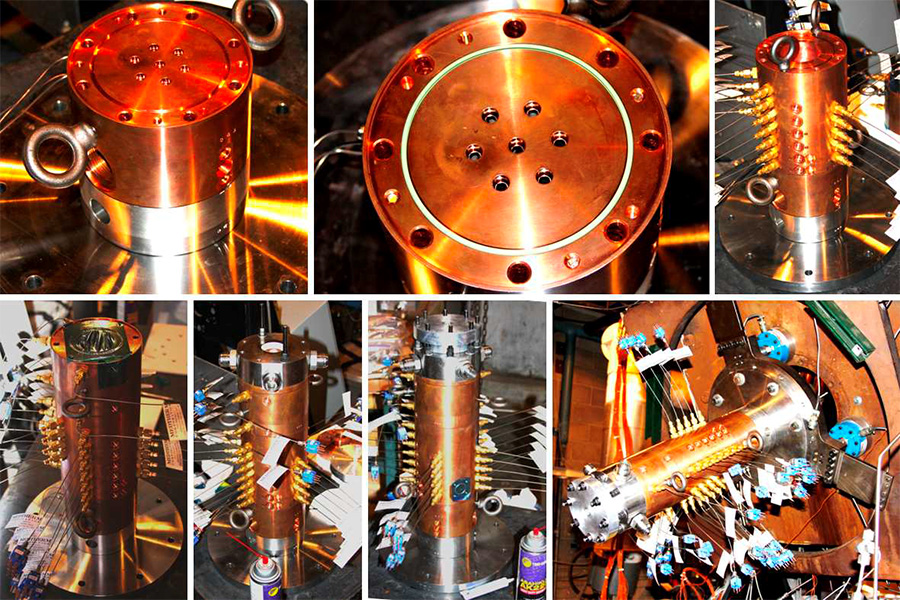

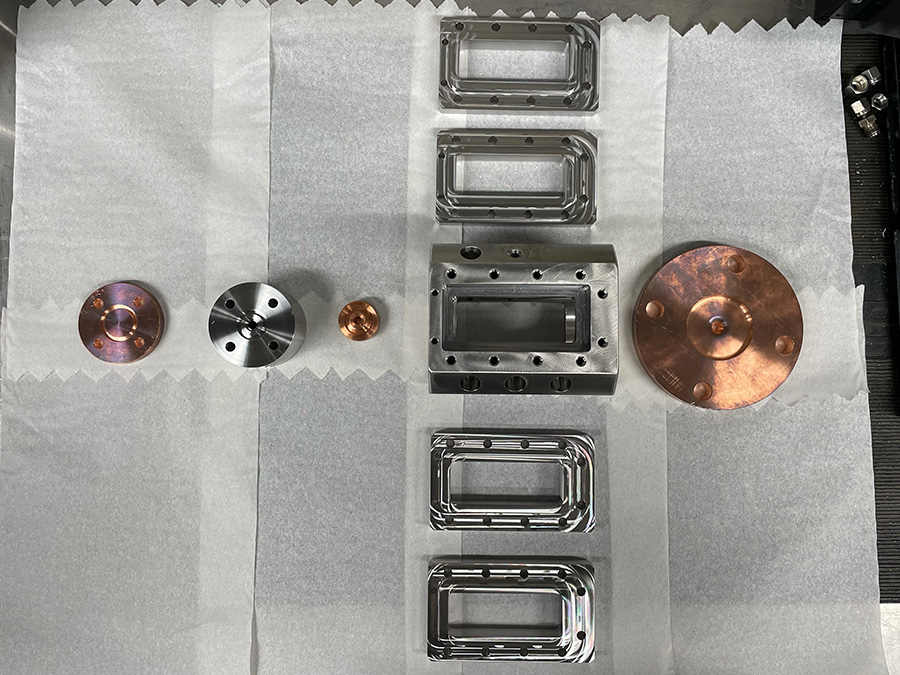

Faculty, staff and alumni are quick to sing the praises of Jerry and others working in the machine shop in Purdue’s Aerospace Science Lab. The custom parts and assemblies they make enable some of the groundbreaking experimental research that happens at Purdue. Jerry has also helped prepare students for their engineering careers by showing them what is possible in a machine shop environment.

John Sullivan, Emeritus Professor

"Jerry is not your average machinist, he is a superb model builder. That goes way beyond machining capability. He works with the students, helps them improve their design, and then goes and builds something that requires lots of skills not just in machining but in assembly.

-Purdue AAE Professor Bill Anderson

I think that one of the things about the shop is that they educate the students on what is possible. Some people walk in the building and they don't know what a lathe is. Jerry is just superb at working with students. It enhances their education just to be able to see how things get built, how any manufacturing place will operate.

Students go out and talk to him, and they end up doing their part differently, doing it much better. To me that's a big part of what he does."

Bill Anderson, Professor

"I have known Jerry for about 20 years. He has made intricate hardware for dozens of projects, both for research purposes and for class projects. All my graduate students who did experiments worked directly with Jerry to fine tune their designs so they could be manufactured with the precision required by the experiment.

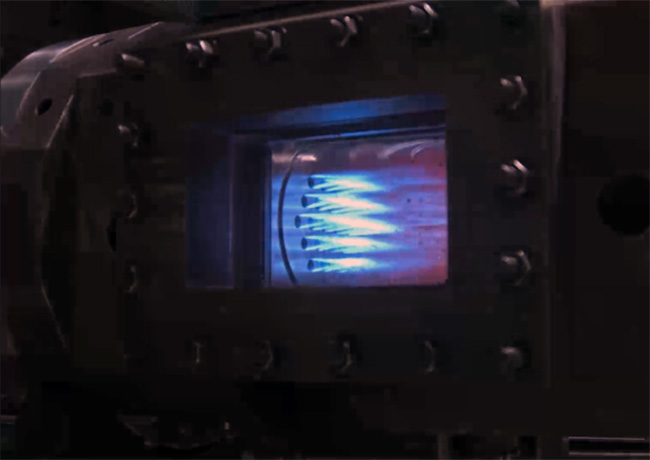

He would provide tours of the machine shop to students enrolled in my Propulsion Design, Build, Test course, and would help them develop designs that could be built in the shop. He would also provide training and supervision to students who wanted to learn how to use the machines. He has made critical contributions to my projects, and many other projects at Zucrow Labs."

-Tristan Shahin, graduate research assistant at Maurice J. Zucrow Laboratories.

Katya Casper (MSAAE ’09, PhDAAE ’12), Senior technical staff at Sandia National Laboratories, aerosciences department

"He's not going to come find you to chat, but Jerry's awesome. You talk to him, he asks you a few questions that are to the point, and makes you something beautiful. It’s unparalleled quality you have at Purdue right there, to help you with your projects.

Grad students are great to work with, but we can be stupid too. It speaks a lot to the machinists that they're patient and will help you no matter what. They would get us out of all these binds. When things don't fit, or parts get stuck, they would drop what they were working on and come fix it for us. They would accept payment in baked goods."

Brandon Chynoweth (MSAAE ’15, PhDAAE ’18), Research Assistant Professor

"The machinists really are unsung heroes. I first met Jerry 10 years ago when I started my MS/PhD work in the Boeing/AFOSR Mach-6 Quiet Tunnel. I would not have a PhD today if it wasn’t for the skill and attention to detail that Jerry put into every part that he fabricated, especially the flared cone models which were integral to my thesis work.

I have seen him make everything from hypersonic wind-tunnel models, to nozzles and combustion rig parts for testing that occurs at Zucrow Laboratories. Jerry has always been willing to provide feedback on the design and machinability of parts, which provide a unique learning opportunity for students that cannot be learned by reading textbooks."

-Ryan Strelau, NSF Graduate Research Fellow at Maurice J. Zucrow Laboratories.

Chris O’Bryan, Aerospace Prototyping Technician

Chris O’Bryan and Scott Williams have been machinists at Purdue for two years, replacing Jerry’s longtime colleagues who both retired in 2020.

"Me and Scott Williams started here in the machine shop on the same day. This is an extremely busy shop, and it's impressive that he held this down by himself. Everything we make here is a one-off, with tight tolerances. They’re parts nobody has ever seen before that the students designed.

Jerry is a silent professional. He lets his actions speak. His work ethic, determination to be efficient… he has a dogged determination to not let a part go out with a blemish on it. Coming here and having a guy like that as a role model is more than I expected.

He loves this shop, it's very much a part of him. He's leaving big shoes to fill."

About Jerry

Jerry Hahn completed the machine tool program at Ivy Tech Community College of Indiana, and right afterward began working at Landis and Gyr, a manufacturer of electric meters. When the company moved some of its manufacturing outside the U.S. in the late ‘90s, he found work in home construction until he could return to his trade three years later. He joined former colleagues from Landis and Gyr in Purdue AAE’s machine shop in 2001.

“It’s interesting work, nothing you normally do in a machine shop. The biggest difference is in setup, everything here is a one-off,” he says. “There are students from all over the place, so I get to meet people with different experiences. Usually they come with prints of parts and see if they can be made. We usually can make anything, as long as we have the machines for it.”

“Every piece I make has my name on it, so I want to be sure that everything I make is to the best of my ability. I'm pretty proud of the stuff I do here,” he says. “When people ask what I do, I say I build rocket motors. That's the short of it.”

Jerry’s wife, Tammy, is retiring from her job in the surgery department at Franciscan Hospital on the same day. They are visiting Florida in January 2023. Afterward, they plan to travel and camp in their motorhome, take long road trips on their motorcycles, and relaxing in their boat on Lake Monroe in Bloomington, Indiana.