NASA Fellowship Recipient Continuing Research on AI-Driven Composites Manufacturing

| Author: | Alan Cesar |

|---|

For Joseph Kirchhoff, receiving a NASA research fellowship grant is just icing on the cake. The recent Purdue graduate is fascinated by composites and loves doing research, but he believes it’s only worth doing if it’s making a positive difference in the world.

“The world is a better place for composites, right? Our airplanes are more efficient, they're stronger, they have a better fatigue lifetime. But let's answer the call. We need to make these materials environmentally friendly,” he says.

One of his driving points is the energy-intensive process of heating an autoclave large enough to cure one of the enormous wing sections for a passenger airliner – it’s mentioned right in the opening of his proposal for the NASA Space Technology Graduate Research Opportunities (NSTGRO) grant, alongside his plan to research recyclable thermoplastic composites to make aircraft manufacturing more sustainable.

As the recipient of a NSTGRO fellowship, Kirchhoff’s work will be a continuation of what he did as an undergraduate researcher in Purdue Aeronautics and Astronautics, and in the Composite Manufacturing & Simulation Center (CMSC).

An Early Start in Research

In high school, Kirchhoff had the opportunity to perform research with a professor at North Carolina State University (NCSU). Dr. Mark Pankow, an associate professor at NCSU who specializes in impact and ballistics testing, gave Kirchhoff a taste of what can happen when you combine dissimilar materials.

“Seeing how composites come together, you take two things that don’t seem like they should be friends, and when you mash them together you get some aggregate of their properties. And it’s almost enchanting in a sense,” he says. “Carbon fiber is really cool.”

His time with Pankow showed Kirchhoff that research is still very accessible to young people with limited experience. He now laughs about some of his early methods, but he found the experience priceless.

“Dr. Pankow opened his lab for me, and his expectation was the same that he would give a grad student. I was a sophomore in high school and that’s a very empowering scenario,” he says. “Just being in a lab talking to grad students, talking with people who go off and do other things, and seeing the material first hand and playing with it — that spring-launched my career.”

Friendship-Driven, Community-Oriented

When Kirchhoff arrived at Purdue, he had three goals: Do really cool research, get good grades, and paint his chest at a football game. He had applied to the top 10 engineering schools that had a football team — not because of his love of the game, but because a great athletics program implied that he could have a balanced life.

“I knew there would be a social aspect to college, and I knew I’d be able to make a lot of friends if I went to football games,” he says. “You can’t paint your chest alone at a football game. You need friends to spell ‘Boiler Up!’”

His social goals also stretched into the community. He was involved with Boilers In Action for three years, and their virtual day of service in 2020 was particularly important to him. “We brought in a US representative, local grassroots-level activists, and someone from the NRDC [Natural Resources Defense Council], to share perspectives on how people are still plugging away at trying to make the world a better place.”

But Kirchhoff’s deepest bonds were forged in his academic realm: the late nights doing homework and learning the subject matter. “The friends I’ve made in AAE, we’re friends for life.”

Improving Composites for a Better World

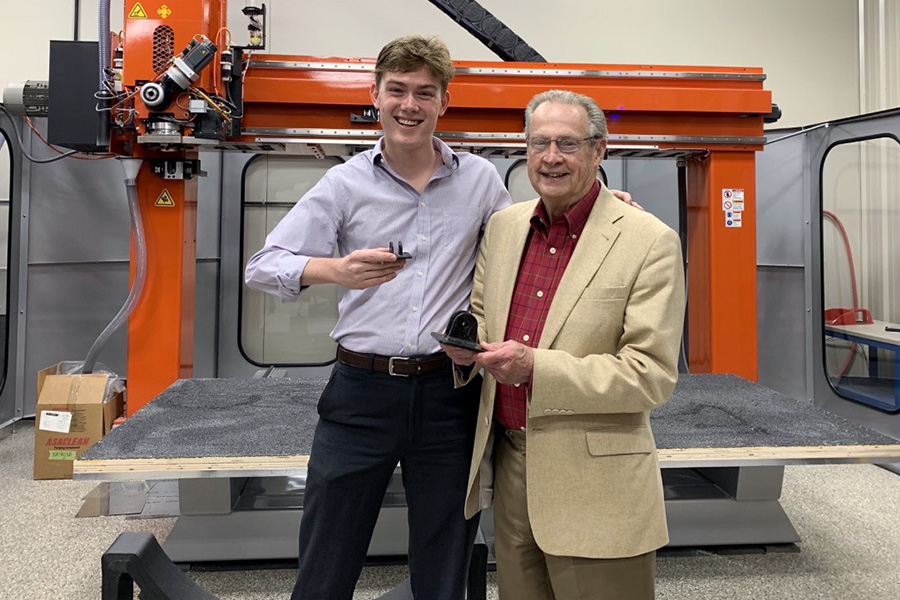

Working as an undergraduate researcher at the CSMC, Kirchhoff received invaluable guidance from its executive director, Dr. R. Byron Pipes. Pipes is the John Bray Distinguished Professor of Engineering at Purdue, under a joint appointment to Aeronautics and Astronautics, Chemical Engineering, and Materials Engineering.

“Dr. Pipes is incredible,” Kirchhoff says. “He’s a really impressive researcher, a giant in our field, but most importantly he’s a really good person. A key role model in my life. From working with him I’ve become a better researcher, matured, and learned how to tackle problems by breaking down the physics.”

The CMSC experience introduced Kirchhoff to the challenges of getting innovative materials flight-certified within the aerospace industry, Pipes says.

“I have been impressed by Joseph’s vision to drive the future of composites in aerospace by improving their predictability and reliability. He has been working in an environment here at Purdue that is rich with academic inquiry into the creation of the ‘digital twin’ of manufacturing processes, and performance of advanced composite materials for aerospace original equipment manufacturers like Boeing and its supply chain,” Pipes says.

Kirchhoff’s proposal for the NASA fellowship is an extension of this “digital twin” concept. He wants to use physics-based modeling to describe an out-of-autoclave manufacturing process of using a thermoplastic resin system, instead of the traditional carbon fiber layup method. Thermoplastics, Kirchhoff says, could be melted down to form new shapes, and so have some degree of recyclability to them.

A computerized model, developed using artificial intelligence and copious amount of prior data, could be coupled with physics for predictive and adaptive control a robotic manufacturing process. In Kirchhoff’s mind, the robot’s control system would use this model along with sensor data to make small adjustments to the manufacturing routine in real time.

Having completed his undergraduate degree in Aeronautics and Astronautics at Purdue, Kirchhoff will pursue his graduate research at University of Texas at Austin, with the Mechanical Engineering department and the Oden Institute with professors Dr. Mehran Tehrani and Dr. Omar Ghattas. “With this fellowship, I am eager to work with NASA collaborators to expand our field by testing with their industry-scale robots. We can test our models on a research platform, and go to NASA and see what works.”