NSF grant could help enable 'self-driving' pharmaceutical lyophilizers

Many pharmaceutical products would not be commercially viable without lyophilization, also called freeze drying. But lyophilization is an expensive and time-consuming process in pharmaceutical manufacturing.

A group of Purdue researchers are hoping to change that by accelerating the transition to automated lyophilization and enabling “self-driving” pharmaceutical lyophilizers, which will enable more cost-efficient manufacturing. The proposed project was chosen by the National Science Foundation for a $750,000 grant to develop real-time sensor technologies, computational modeling and bioanalytical tools for closed-loop lyophilization.

“We are very excited about this project being supported by NSF Partnership for Innovation program, which helps transition research from the lab into the market for societal benefit,” said Alina Alexeenko, a professor in AAE, founding co-director of Purdue’s Advanced Lyophilization Technology Hub (LyoHub), and the principal investigator on the project.

Timothy Peoples, the managing director of Purdue Foundry; Dimitrios Peroulis, the Michael and Katherine Birck Head of the School of Electrical and Computer Engineering; and Elizabeth Topp, founding co-director of LyoHub and professor in industrial and physical pharmacy, are co-PIs on the project. On this project, Purdue partnered with Millrock Technology, a third-generation manufacturer of freeze-drying equipment located in Kingston, New York.

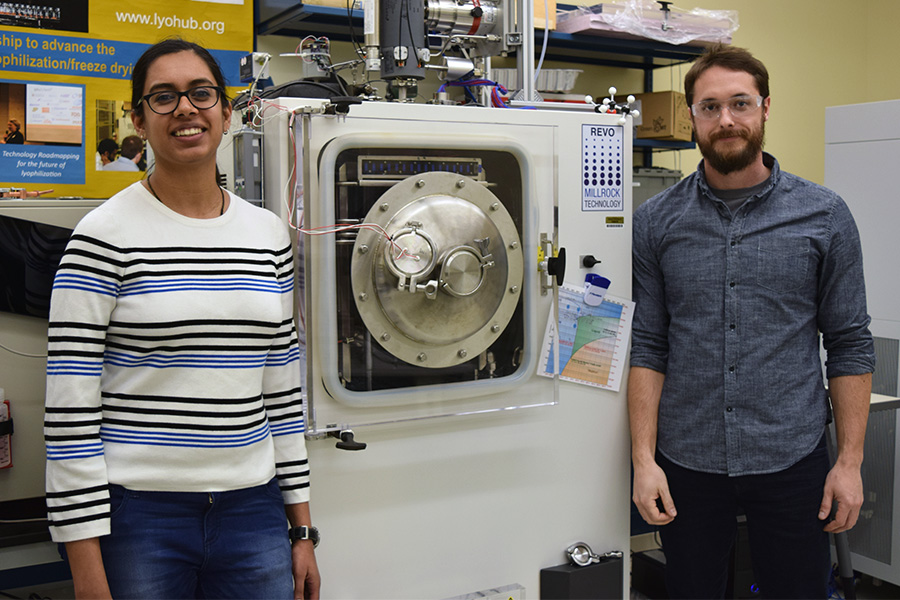

AAE graduate students Gayathri Shivkumar and Andrew Strongrich have been heavily involved in the research, as Shivkumar’s models and Strongrich’s sensor designs are being used in the project.

Lyophilization is a stabilizing process that is used to preserve the long-term safety, strength, and quality of pharmaceutical products. It’s accomplished by using a sterile, vacuum environment to remove water while maintaining chemical or biological function of products. The rarefied fluid dynamics and heat transfer conditions encountered at the low pressures used in lyophilizers are very similar to the high-altitude aerodynamics problems Alexeenko’s research group specializes in solving.

Current methods don’t have real-time control and real-time measurements, Shivkumar says. All inputs are fixed at a constant value.

“That’s how it’s freezing. That’s how it’s drying. They have a set recipe that’s tried and tested over time, but that’s not necessarily the most optimal cycle,” Shivkumar says. “So if you’re able to get real-time measurements, you can optimize it. Not just to the most optimal, single-point value, but at every instant of time, you can keep changing the set points, depending on what’s going on inside the dryer. That’s what I wrote a model for. To basically model heat transfer. It’s a very simplified heat transfer model. It basically shows how, if you’re able to constantly change the conditions, depending on what you’re measuring, then you’ll be able to dry everything much faster.”

Faster and more optimal drying could mean a considerable time and cost savings.

A typical production lyophilization cycle usually takes a minimum of a few days to as many as two weeks. The process is lengthy because of overly conservative cycles due to lack of in-process product monitoring and closed-loop control.

Some technologies are moving toward closed-loop control, but it is not widely applied, Strongrich says. But that’s the idea behind Purdue’s project, spurred by its sensors and modeling. By closing the loop, taking measurements of the product state during its drying, and feeding that back to a controller, it is, essentially, an autopilot system.

“If you’re able to cut down the time by, say, 50 percent, that’s going to save you a lot of money. That’s where Drew’s sensors come in because his sensors are what measure and then feed it back to the code, so it figures the most optimal run point at every instant of time,” Shivkumar says. “Right now, we have a model that shows if we were to do closed loop, then we would save a lot of time. But it hasn’t actually been implemented yet. That’s what this grant is for.

“The biggest roadblock is getting that real-time measurement at every instant of time at each location and being able to integrate that all into one code to get the most optimal single-point at each instant of time. That’s where, once his sensors are working perfectly and they’re able to beam out this information, we’ll have to take all of that, consolidate into one code and control it using that code.”

When using freeze drying, each formulation has its own “speed limit,” Strongrich says. For this research, that speed limit is temperature. Each formulation has a critical temperature it can’t exceed or it will collapse. The point of lyophilization is to freeze dry the liquid product so it can remain viable for months or, even, years. If it collapses, that doesn’t happen.

That’s why the key parameter is how fast a product is drying, or its sublimation rate. By knowing the local pressure, researchers have a better estimate of what the product state is, and that information can be used to directly compute what the sublimation rate is by using fundamental fluid mechanics.

That’s where the sensors come in. They’re inserted into vials among the batches and measure pressure, so the sublimation rate can be determined. The sensors are battery-powered and broadcast results wirelessly in real time into a model to give sublimation rate, which inputs into the code.

“It can determine then how to adjust the dryer such that we’re right on the brink of that collapse temperature but never exceeding it. Because the warmer we go, the faster we dry. That’s what it comes down to,” Strongrich says. “Nothing like this sensor exists out there for this. There’s one sensor out there, but it’s not real-time. It just logs pressure, doesn’t beam it out real time. These sensors are temperature compensated and very optimized for power consumption.”

Millrock provided the machine researchers are using for the NSF project at LyoHub in Purdue’s Discovery Park.

“Millrock Technology is excited to work with Purdue on this NSF project,” says T.N. Thompson, Millrock’s president. “The sensors and concepts proposed by Purdue in combination with the techniques and technologies developed by Millrock throughout the years is promising to produce major improvements in the freeze-drying process. Better process control through continuous measurement of critical process parameters will enable maximum throughput while keeping the pharmaceutical product safely below its critical temperature."