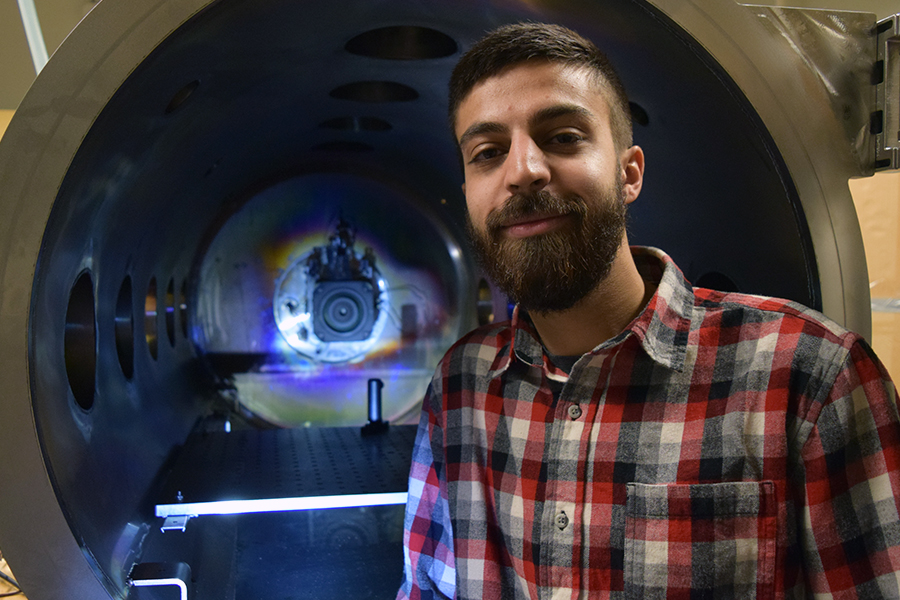

The 20 Twenties: Adam Patel

Adam Patel says, almost begrudgingly, that he has a “boring backstory.”

Patel didn’t grow up helping his dad build airplanes. He didn’t dream of becoming a pilot. He wasn’t enamored with space exploration. He didn’t have any engineers — let alone aerospace engineers — in his family.

But that certainly hasn’t made what Patel has done since he’s been in Purdue’s School of Aeronautics and Astronautics any less impactful.

Patel recently was named one of “Tomorrow’s Engineering Leaders: The 20 Twenties,” an award from Aviation Week Network in collaboration with the American Institute of Aeronautics and Astronautics. Patel is one of three Purdue students selected for the award. He won’t attend the ceremony in Washington D.C., though, as he’s scheduled to start a study abroad program in Greece.

Still, that does little to tarnish the shine on the honor, especially considering it recognizes the work he’s done with Alexey Shashurin, an assistant professor in AAE. It is Shashurin who prompted Patel’s research in electric propulsion.

In high school, Patel was intrigued with the idea of a career in the defense industry. He figured it’d be noble, working to keep the U.S. safe. To that end, he started Patel Ballistics, a company that specializes in flare launchers. He intended to stay in the defense sector after enrolling at Purdue. But those intentions shifted his second collegiate year.

When Patel was reading about projects offered through Purdue’s Summer Undergraduate Research Fellowship (SURF) Program, he paused at Shashurin’s work in evaluating the performance of alternative propellants in Hall thrusters. Patel did some homework — and was wowed.

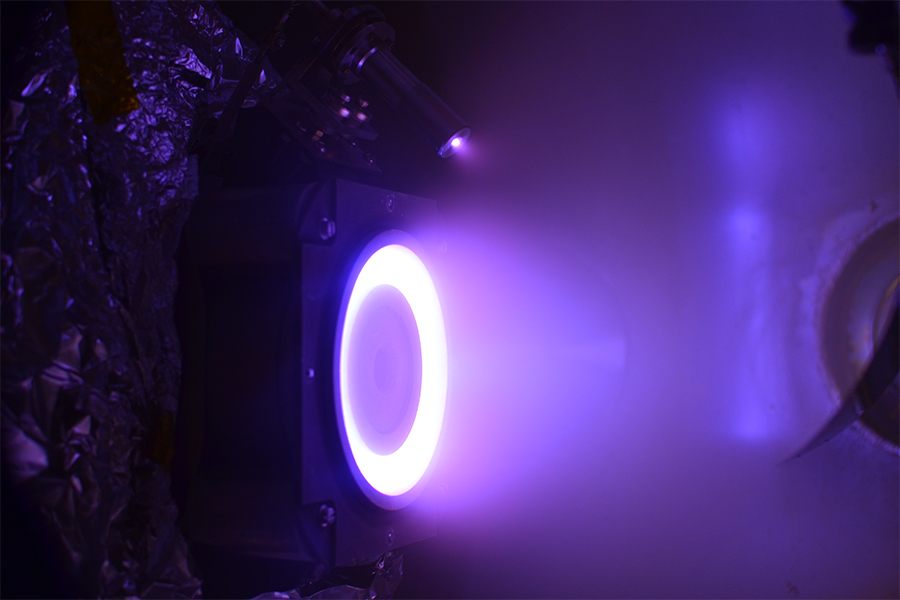

“It’s, like, sci-fi. You’re accelerating plasma,” Patel says, smiling.

So Patel reached out to Shashurin and asked if he could work on the project. Shashurin not only said yes but also allowed Patel to have considerable responsibility within the project. Patel won best poster in Combustion and Energy at the end of the SURF Program.

More importantly, Shashurin’s passion for electric propulsion rubbed off.

One year later as a senior, Patel still is working closely with Shashurin but now on a new project: Developing a novel low-energy surface flashover (LESF) igniter subsystem for pulsed plasma accelerators.

Patel had been researching propulsion systems for CubeSats, and electric propulsion offers efficiency advantages over chemical propulsion, being able to travel farther with the same amount of fuel.

Pulsed plasma thrusters (PPT) are ideal for applications in CubeSats for attitude control, precision spacecraft control and low-thrust maneuvers. A PPT is a “simple device,” Patel says, that consists of two electrodes positioned close to the propellant source. An ignitor produces a "spark" that allows a discharge of the energy storage unit between the electrodes, creating and accelerating plasma.

The issue is PPTs produce so little thrust that there needs to be a lot of pulses to use all the propellant. With current igniter systems, one can only do thousands of pulses, and a PPT needs more than that.

Surface flashover technology is usually an “undesirable effect in industry,” Patel says, because it places voltage limits on capacitors. But in low vacuum and for Patel's research purposes, it’s actually a good effect, Patel says. Low energy surface flashover is composed of a thin insulator between two electrodes. By utilizing a high-voltage pulser and limiting current, sustainable breakdown over the dielectric can occur. This seed plasma will collide and ionize propellant in the accelerator channel — turned into plasma as well — which is then accelerated using a capacitive arrangement. The approach achieved at least 1.5 million pulses. And it could have been more, Patel says.

“The way we’re producing LESF is pretty caveman. We just slap the electrodes together,” Patel says. “But there are a lot of new techniques that can be used for manufacturing, such as micro-electromechanical systems (MEMS) printing. We can print on ceramics and get an even smaller gap for breakdowns, so we should be able to reduce the voltage even more. Further, there are some other interesting noncontaminative dielectrics we can utilize in LESF ignitors.”

That would allow the ignition and propulsion systems to function reliably for a long time. With rapid increases in CubeSat mission complexity, such a thruster is in high demand.

Though Patel will graduate in August with his bachelor’s, he’d like to continue to do research. He plans to start grad school in the fall — without an internship in between. He hasn’t had any internships during his time at Purdue, he says because he likes research. Simply, he enjoys problem-solving.

Each week, he will meet with Shashurin, who recaps new advancements in plasma. Each day, Patel gets excited about the future.

“I like to experiment. There’s a lot of exotic technologies that haven’t been applied yet,” he says. “It’s really cool. You realize the stuff you’re doing, there are so many different implementations of it. This pulsed plasma thruster, you could go that route, learn more and more. There’s this pulsed inductive thruster, which instead of using an electric field, it uses a magnetic field.

“It just keeps going on. It doesn’t stop. I can’t find an end to it.”

And Patel plans to continue to grow his company, too. He already has several clients and is negotiating a contract now to supply an army overseas. The last several months, Patel Ballistics has manufactured new products, too, including optic mounts, and Patel has been researching the use of graphite reinforced polymers for flare guns. It’d be stronger than steel per weight and lighter.

“Usually during the day, I do the classes and the research, and I come home at night and try to do that,” he says.

More on AAE's 20 Twenties: Aaron Blacker, Alexis Harroun