Thrust Reversing

Although most modern aircraft brakes are sufficient during normal conditions, when runways become icy or snow covered, an additional method of bringing the aircraft to stop is needed. A simple and effective way to reduce the landing distance of an aircraft is to reverse the direction of the exhaust gas stream. Thrust reversal has been used to reduce airspeed in flight but is not common on modern vehicles.  Many high by-pass ratio engines reverse thrust by changing the direction of the fan airflow. Since a majority of the thrust is derived from the fan, it is unnecessary to reverse the exhaust gas flow. Propeller-powered aircraft reverse thrust action by changing the pitch of the propeller blades. Usually, a hydro-mechanical system is used to change the blade angle, giving a braking response when activated.

Many high by-pass ratio engines reverse thrust by changing the direction of the fan airflow. Since a majority of the thrust is derived from the fan, it is unnecessary to reverse the exhaust gas flow. Propeller-powered aircraft reverse thrust action by changing the pitch of the propeller blades. Usually, a hydro-mechanical system is used to change the blade angle, giving a braking response when activated.

Ideally, the gas should be directed in a completely forward direction; however, this is not possible, mainly due to aerodynamic reasons. A discharge angle near 45 degrees is usually chosen, resulting in a proportionally less effective reverse thrust than the thrust of the same engine in its normal direction.

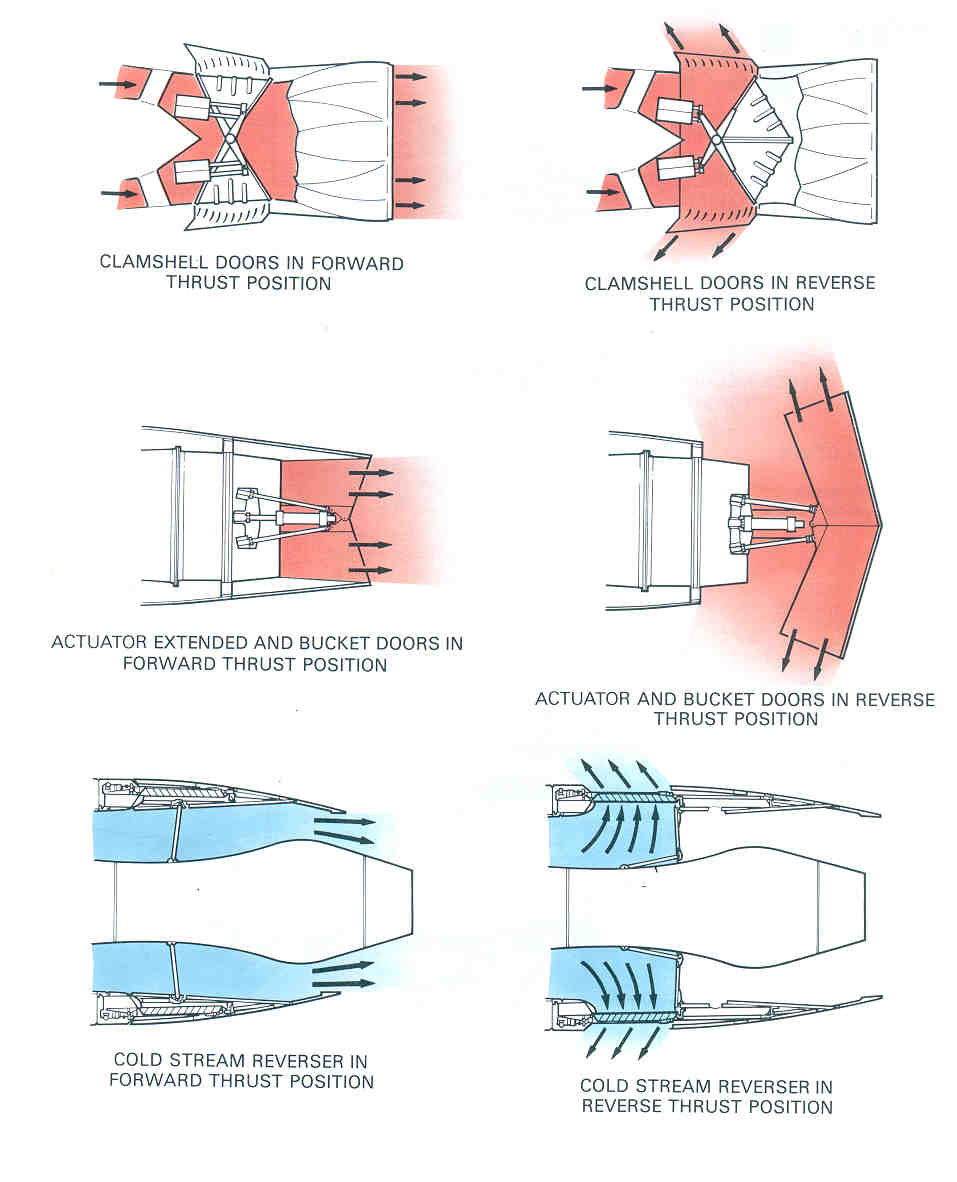

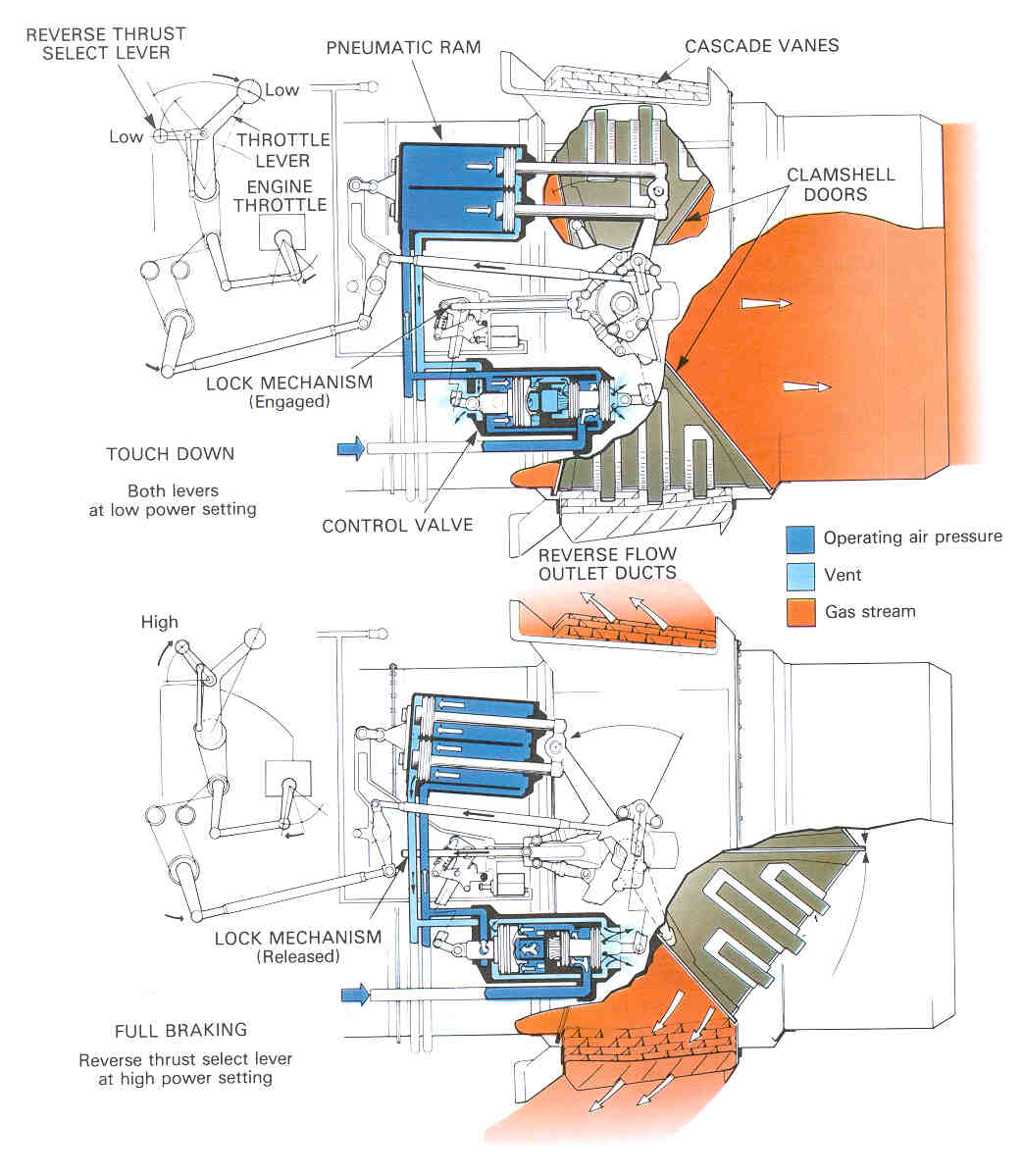

There are several methods of obtaining reverse thrust on turbo-jet engines: (1) camshell-type deflector doors to reverse the exhaust gas stream, (2) target system with external type doors to reverse the exhaust, (3) fan engines utilize blocker doors to reverse the cold stream airflow. (shown right)  The camshell door system is a pneumatically operated system. Normal engine operation is not affected by this system, because the ducts through which the exhaust gases are deflected remain shut until reverse thrust is activated by the pilot. When this happens, the clamshell doors rotate to uncover the ducts and close the normal exit. Then the thrust is directed in a forward direction by vanes to oppose the aircraft's motion. (shown left)

The camshell door system is a pneumatically operated system. Normal engine operation is not affected by this system, because the ducts through which the exhaust gases are deflected remain shut until reverse thrust is activated by the pilot. When this happens, the clamshell doors rotate to uncover the ducts and close the normal exit. Then the thrust is directed in a forward direction by vanes to oppose the aircraft's motion. (shown left)

The bucket target system is a hydraulically actuated system that uses bucket type doors to reverse the hot gas stream. The thrust reverse doors are actuated by a conventional hydraulic powered pushrod system. The actuator incorporates a mechanical lock in the extended position. In the forward thrust mode the bucket doors form the convergent-divergent final nozzle for the engine.

The cold stream reverse system is actuated by an air motor. The output is converted into mechanical movement by a series of flexible drives, gearboxes and screwjacks. During normal operation, the reverse thrust cascade vanes are covered by the blocker doors. On selection of reverse thrust, the actuation system folds the blocker doors to blank off the cold stream final nozzle, thus diverting the airflow through the cascade vanes.