Faculty virtually transforming Purdue

As a bright light to these unprecedented times, Purdue already has taken steps to develop virtual labs — and the timing couldn’t be better as the University moved to remote instructional delivery. One example of this transformation is in the College of Engineering.

The virtual lab movement revved up there in 2016 with the design and implementation of a virtual lab for AAE 204 - Aeromechanics II. The effort was led by Michael Sangid, the Elmer F. Bruhn Associate Professor of Aeronautics and Astronautics, and Alberto Mello, a visiting professor now at Embry-Riddle Aeronautical University.

"The year after Dean Mung Chiang arrived, he asked if I could scale this, serving as a dean’s fellow for virtual labs across the college to design, develop, implement and assess virtual labs at scale," Sangid said.

It was a turning point, said Dimitrios Peroulis, the Michael and Katherine Birck Head of the School of Electrical and Computer Engineering. Peroulis serves as a special adviser to the dean for online learning.

"Dean Chiang challenged the engineering faculty to innovate in the online learning space," Peroulis said. "While we recognized that we did not have all the answers, we understood it was important to lead in this area for the benefit of our students on campus and around the world. It quickly became clear that, although we have several leading online programs, we needed to enhance our experiential learning options."

In Fall 2018, the college and five of the engineering schools joined together to submit a virtual labs proposal to the Office of the Provost for an Instructional Innovation Grant. To assemble the application, Sangid served as the principal investigator and collaborated with the Envision Center, Peroulis (then associate dean in the college) and other faculty across the college. Taking part were schools of Aeronautics and Astronautics, Civil, Chemical, Electrical and Computer Engineering and Engineering Education, which would assess the outcomes so lessons learned and best practices could be shared.

Their joint application was based on the same principles, yet would give the schools flexibility to develop labs based on their own disciplines. Each would partner with the Envision Center to create software, videos, graphics and virtual experiments.

The college was awarded a $100,000 Innovation Grant in January 2019. The college and the schools also contributed — each school chipped in a total of $35,000 and teaching assistant support — and now many of these labs are in various stages of development. Some, like the sophomore-level basic laboratories in ECE, are up and running. Another call for proposals from the College of Engineering went out in 2019.

"We did not intend to replace the physical labs, but to make students' time there more effective,” Peroulis said. "We also looked to online labs as a way to ensure quality and consistency from year to year and section to section — and we have some large sections — because everyone in a course would see the same videos, go through the same virtual and physical experiments and focus on the same learning objectives."

In the School of Aeronautics and Astronautics, continuing lecturer Waterloo Tsutsui teaches two labs that offer both virtual and on-site components.

His students use the virtual lab before they come to the hands-on lab so they can visualize and understand principles in advance. They then are more prepared when they get to the physical lab.

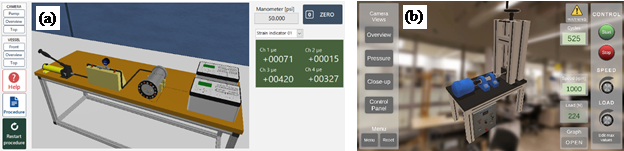

To understand the mechanical property of materials, students in his virtual lab elongate a virtual specimen bar and analyze its tensile properties. They also test pressure vessels and trusses that are important in engineering structures, such as aerospace and ground vehicles, bridges and buildings. Virtual experiments simulate mechanical operations, and depending on what is being tested, can apply various amounts of external loads (e.g., force, moment, and torque) onto specimens to obtain outputs (e.g., strain and displacement). Then, students compare the experimental results against the theoretical results to see if the experiments concur with expectations/theory. They can run the virtual test in many different ways and have more testing options than they would have time to do in the hands-on lab. Because they run the same tests in both the virtual and the physical labs, students can compare their own results.

"It becomes a quick test, letting them compare their hands-on results in real time to those from the virtual lab," Tsutsui said, based on input from his students. "It provides a reference to troubleshoot potential errors immediately after the experiments and/or identify potential errors after the experiments without going into detailed theoretical analysis."

The virtual lab also makes possible some of the experiments that cannot reasonably be performed during hands-on labs due to time, space and safety limitations. For instance, the virtual lab allows users to conduct time-consuming fatigue experiments (i.e., time) on a very large structure (i.e., space) in a chemically hazardous environment (i.e., safety).

Students' feedback has been generally positive. Due to the interactive nature of learning with the virtual labs, students say that they understand the material more readily. When considering the large experimental error associated with the hands-on lab, some even say using the virtual lab is easier to understand than the physical lab.

The virtual labs not only provide personalized feedback to students, they inform the instructors, Peroulis said. If a large group is making the same mistake, the instructor can pinpoint where knowledge gaps are.

"The virtual lab doesn't take the place of the hands-on lab, but it enhances," Tsutsui added. "It might not be as good on some levels, but it better prepares students for the hands-on lab. They can run more versions of an experiment and they can do it remotely from anywhere with an Internet connection."

This story appeared in the Office of the Provost's March newsletter.