The team has been awarded a grant from the National Institute for Occupational Safety and Health (NIOSH), a part of the Centers for Disease Control and Prevention (CDC), to develop cutting-edge bioinspired wearable sensors aimed at protecting workers from injuries that occur in manual material handling (MMH) jobs.

The project focuses on creating an automated, scalable solution that predicts injury risks using innovative sensor technology and artificial intelligence. The team will collaborate on developing nanotech research to address ergonomic issues in the workplace.

Manual material handling are physical tasks like lifting, pushing/pulling, and assembling/disassembling. They occur in many industries such as manufacturing and agriculture. Despite advancements in automation, these tasks continue to put workers at increased risk for workplace injuries. To determine whether a job is unsafe, safety practitioners often need to know each worker’s exposure to risk factors such as posture, repetition, and force exertions. Objectively measuring these factors with wearable devices would enable unprecedented accuracy, precision, and safety in MMH jobs, as well as in other societally pervasive fields such as human-robotics teaming and mixed realities.

Yu, the project's principal investigator (PI) and the

National Safety Council's Rising Stars of Safety awardee, states "contributors to workplace injuries are often multifactorial and many of these risk factors are very challenging to accurately and reliably assess. Our work developing low-cost and durable nanosensors have the potential to provide objective evidence for workers and safety professionals to monitor and predict injury risks at scale."

Wu states “most existing wearable technologies rely on massively distributed sensors to detect the posture or force distribution, significantly increasing the manufacturing and computational complexity. Leveraging our prior achievement in wearable development and inspired by human touch sensing capability, we propose to create the fundamental knowledge and technical capability for screen printing nanoscale semiconductors into frugally designed wearable sensors that can monitor and predict injury risks.”

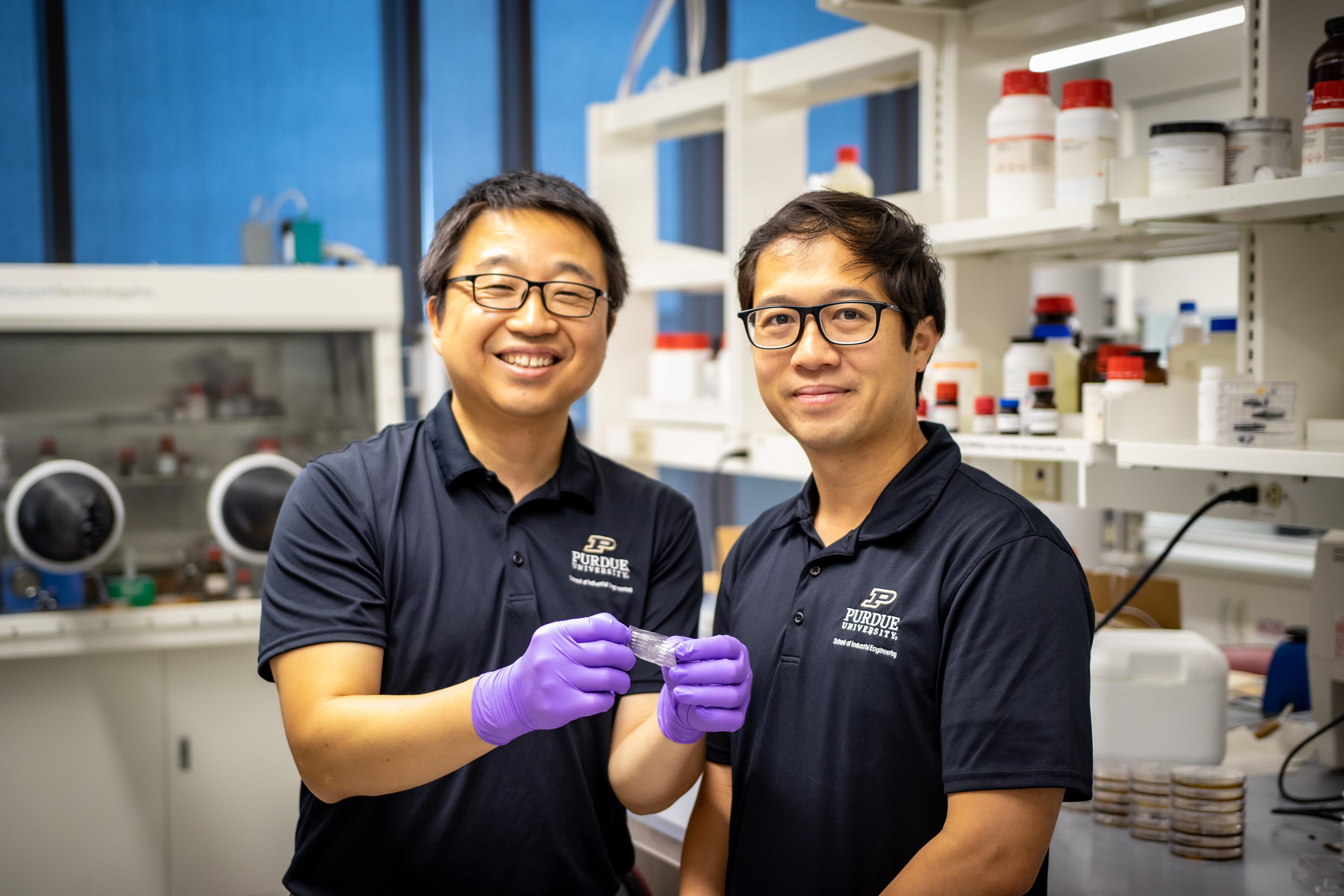

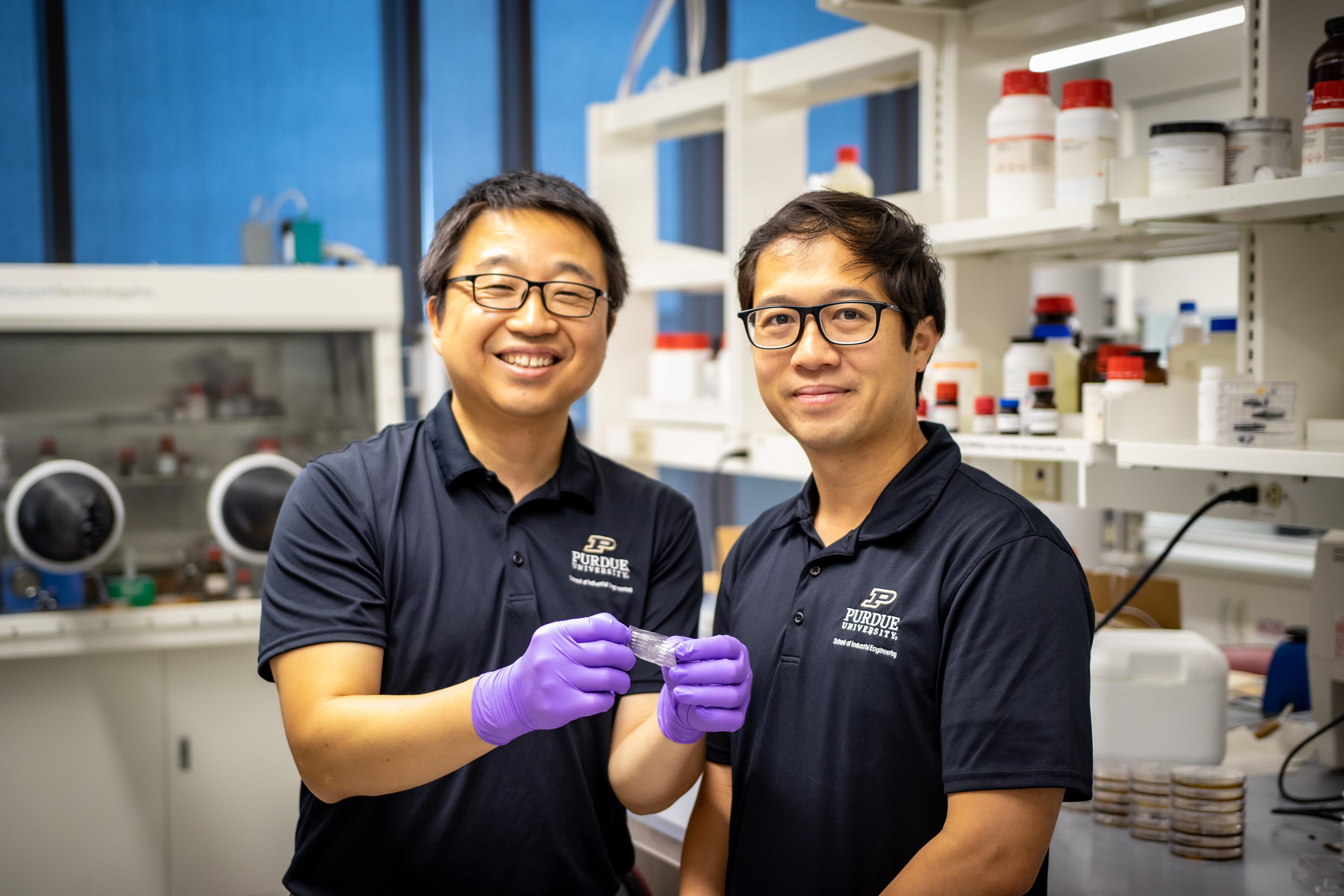

Professor Wenzhuo Wu (Left) and Associate Professor Denny Yu (Right).

The proposed solution aims to address these gaps with low-cost, sensitive wearable sensor systems based on screen-printed nanoscale semiconductors. The sensors, paired with advanced deep-learning algorithms, will automatically and objectively measure the key metrics outlined by the American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Value (TLV) for Hand Activity Level (HAL) – an assessment tool designed to protect workers from upper extremity injuries.

The research stands to make a significant impact on workplace health and safety, particularly in industries where manual material handling is prevalent. The technology's potential for widespread use could transform how employers assess and manage injury risks, leading to safer work environments and a reduction in musculoskeletal disorders (MSDs)-related injuries.

Related Links:

Project Abstract @ NIH.gov

Healthcare Ergonomics Analytics Lab (HEAL)

Wu Group Lab