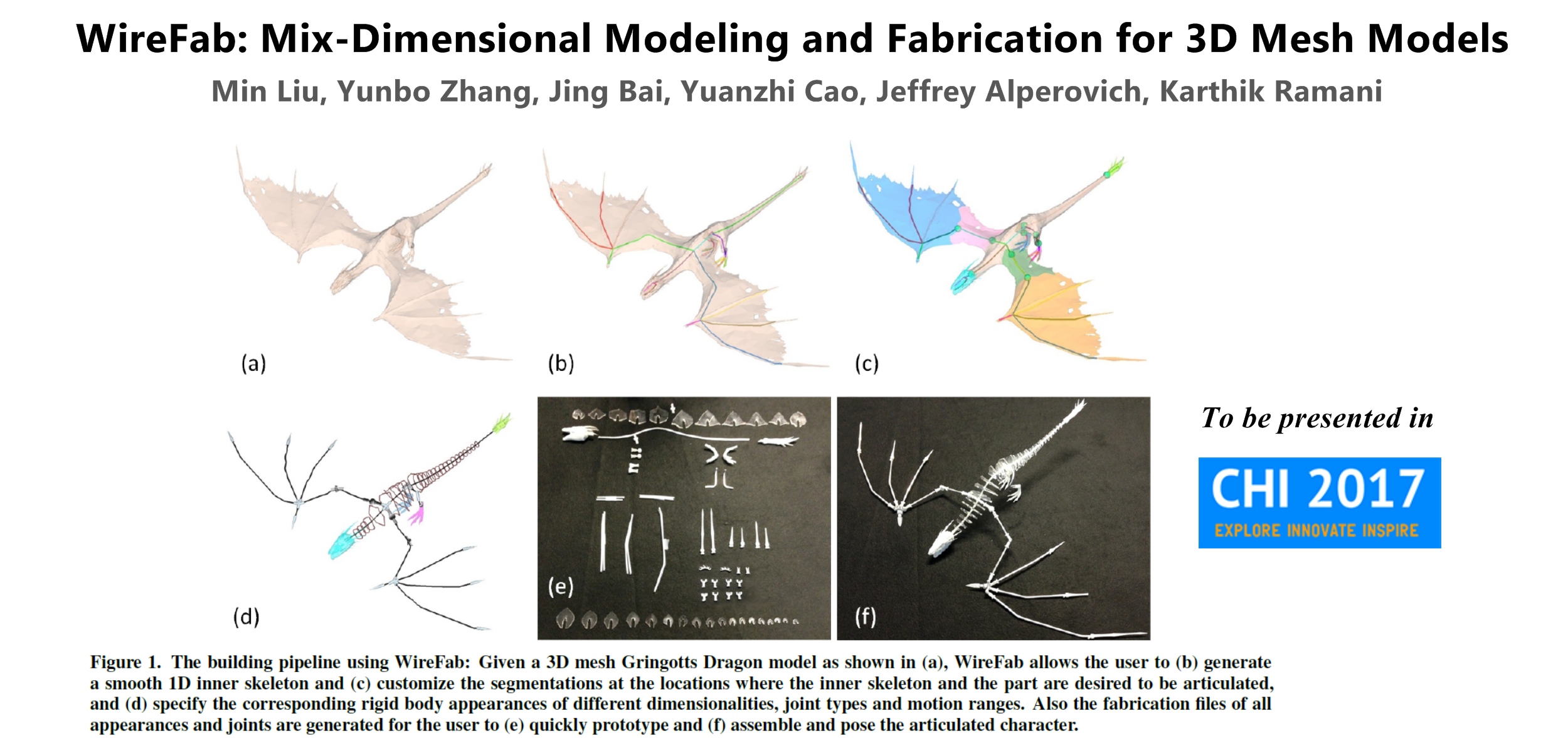

We propose WireFab, a rapid modeling and prototyping system that uses bent metal wires as the structure framework. WireFab approximates both the skeletal articulation and the skin appearance of the corresponding virtual skin meshes, and it allows users to personalize the designs by (1) specifying joint positions and part segmentations, (2) defining joint types and motion ranges to build a wire-based skeletal model, and (3) abstracting the segmented meshes into mixed-dimensional appearance patterns or attachments. The WireFab is designed to allow the user to choose how to best preserve the fidelity of the topological structure and articulation motion while selectively maintaining the fidelity of the geometric appearance. Compared to 3D-printing based high-fidelity fabrication systems, WireFab increases prototyping speed by ignoring unnecessary geometric details while preserving structural integrity and articulation motion. In addition, other rapid or low-fidelity fabrication systems produce only static models, while WireFab produces posable articulated models as user’s desire.

[gview file=”https://Engineering.Purdue.edu/cdesign/wp/wp-content/uploads/2016/12/wirefab-chi2017_final.pdf”]