Purdue Process Safety & Assurance Center (P2SAC) 10th Anniversary

Established in 2014, Purdue’s Process Safety & Assurance Center (P2SAC) began with a handful of company representatives and members of the Davidson School of Chemical Engineering’s (ChE) Industrial Advisory Council. A decade later, P2SAC now hosts biannual conferences on Purdue’s campus, with over 100 registrants, 23 sponsor companies, and a growing number of interested companies in attendance.

P2SAC serves as a nexus for advancing chemical process safety education and research. The focus is on specific industry safety sectors such as oil and gas, chemical, pharmaceutical, and technological industries. P2SAC collaborates with industry partners via research, specialized courses, and consultation to help contribute to improving safety standards worldwide.

“Having been there since the beginning of P2SAC a decade ago, it is amazing how the Center has grown with a diverse mix of companies all recognizing the importance of process safety to their operations," commented Prasad Goteti of Honeywell.

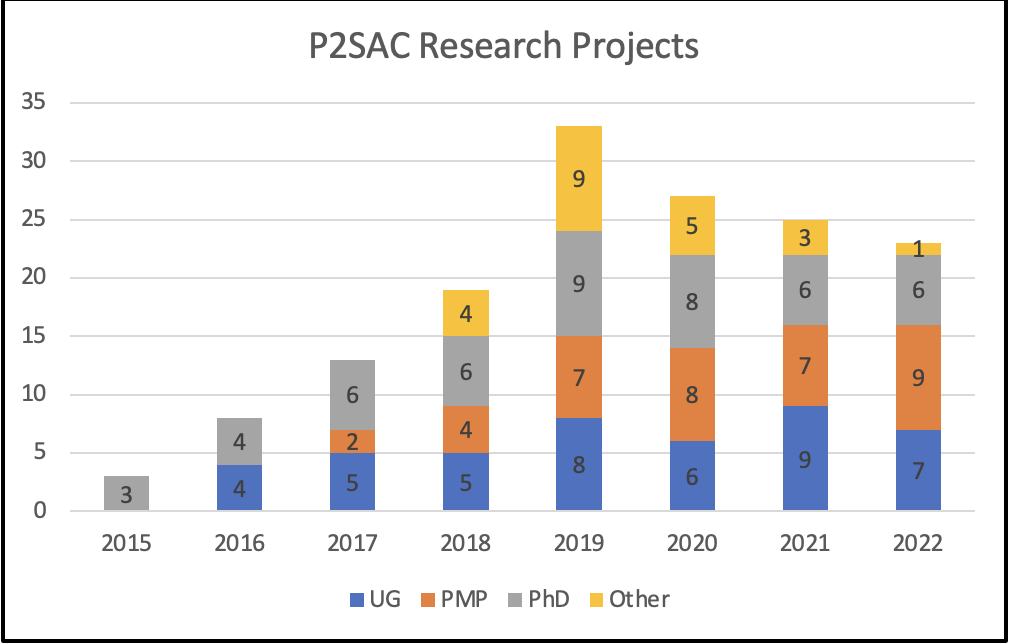

Throughout the years, the P2SAC’s commitment to process safety related research projects has grown to approximately 25 projects annually, and has led to beneficial collaborations with graduate, Professional Master’s Program (PMP), and undergraduate students.

Ray Mentzer, the Executive Director of P2SAC, notes that recent incidents like the 2023 East Palestine, Ohio train derailment and the 2017 Didion Milling facility explosion in Cambria, Wisconsin affected thousands of residents and further underscore the critical importance of P2SAC’s work in process safety.

“We’re proud to be one of the few chemical engineering departments to teach and require a rigorous senior level course in process safety, where incidents such as these are analyzed so students understand the design, maintenance, and operational expectations and implications," commented Dr. Sangtae Kim, the Jay and Cynthia Ihlenfeld Head of Chemical Engineering. "With P2SAC, students get hands-on experience through diverse research projects, with over 1,500 students completing the process safety class and 150 participating in research initiatives.”

P2SAC's projects span various sectors, including pharmaceuticals, oil & gas, chemicals, manufacturing, and consulting. Sponsors exclusively fund Ph.D. research projects focused on battery safety, gas detectors, erosion, flow assurance, and machine learning.

Range of P2SAC Projects

"I feel we’re now hitting on all cylinders with the range of companies and projects pursued each year," commented Osman Basaran, Burton and Kathryn Gedge Professor of Chemical Engineering and Academic Director of P2SAC. "While many pharmaceutical companies are actively engaged as P2SAC sponsors, there are also major oil and gas, chemical, manufacturing and consulting firms in our Center. Sponsor funding is solely used to fund PhD research with half a dozen faculty in areas, such as battery safety, gas detectors, erosion and flow assurance, and machine learning. Industry sponsors dialog with faculty and select the projects for funding."

Professor Raj Gounder, R. Norris and Eleanor Shreve Professor, commented, "When I first became involved with P2SAC around a decade ago, I knew little about process safety. But I have now learned a lot about the area through interactions with many P2SAC members over the years, and have now published 15 papers in this area with P2SAC support."

PMP and undergraduate projects range from laboratory to computer based, including gas detector design and placement, bioprocessing, dusts, ocean-based CO2 removal, multi-disciplinary Artificial Intelligence, organizational health, and analysis of company ESG performance.

Project Summaries

Reactivity of molecules of interest to pharmaceutical industry – is an excellent example of a project involving PhD students in Professor Savoie’s research group, along with PMP and undergraduate researchers over the past three years. It involves eight companies with bi-weekly calls. The companies provide experimental heat of reaction / decomposition data, while the students model the molecular structures using group contribution models in the industry standard CHETAH software and Purdue machine learning based TCIT software, Figure 3. Dozens of molecules have been studied involving half a dozen students over the three years, with multiple publications. In general, TCIT has been found more straightforward to use, not requiring various component substitutions, and predicts the data within ~20%. "This work is particularly noteworthy and the subject of a multi-company publication, demonstrating collaboration among pharmaceutical competitors in the spirit of enhancing process safety, critical to all of us," commented Roy Flanagan of GlaxoSmithKline.

Hazards associated with hydrogen production and transportation – Many have proposed fueling parts of our economy with hydrogen, as an alternative to hydrocarbon-based fuels. However, the hazards that must be addressed before this transition occurs have not been thoroughly studied. After a survey and analysis of over a dozen hydrogen production technologies, PMP students performed hazard assessments of three primary production technologies: SOEC (Solid Oxide Electrolysis Cell, Figure 4), Alkane Electrolysis Electrolyzer, and Proton Exchange Membrane. AcuTech, ExxonMobil and Kenexis representatives mentored the students. Then, in the fall of 2023, two undergraduates analyzed incidents involving hydrogen (as well as ammonia and CO2) pipelines, mentored by ExxonMobil and BP. They examined the frequency of leaks, outcomes (volume released, fires, explosions), pipeline material, etc. Such studies are needed to fully understand the hazards and risks associated with more widespread use of such fuels.

Applicability of Artificial Intelligence (AI) tools to process safety – A very ripe area for study, involving two undergraduates, Professors Can Li and David Bernal, and P2SAC sponsors PSRG and ACC (American Chemical Council), culminated in a student presentation at the December P2SAC conference. The focus was on ChatGPT’s ability to perform various process safety related analyses, including development of operating procedures, creating HAZOPs and performing dispersion modeling. Professor Can Li noted that, "This area holds tremendous promise, but our work clearly demonstrates significant limitations at this time. Our studies will continue both at the PhD and undergraduate levels, to push frontiers, as the technology evolves."

To learn more about P2SAC, visit the website: engineering.purdue.edu/P2SAC or email Professors Basaran (obasaran@purdue.edu) or Mentzer (rmentzer@purdue.edu).