CISTAR professors, Agrawal and Gounder, awarded grant to advance the production of sustainable aviation fuel

Purdue University’s Center for Innovative and Strategic Transformation of Alkane Resources (CISTAR) has forged a pivotal partnership with Susteon, a technology company known for its integration of industry, government, and academic research to develop innovative decarbonization technologies. This collaboration, led by Susteon with professors Rakesh Agrawal and Rajamani Gounder as partners, was awarded a $5.5 million total award from the Department of Energy’s Advanced Research Projects Agency–Energy (ARPA-E) under its GREENWELLS initiative, aimed at advancing the production of sustainable aviation fuel (SAF).

The collaboration between CISTAR and Susteon focuses on developing cutting-edge technologies that address the urgent need for sustainable energy solutions in the face of growing greenhouse gas emissions leading to climate change. The project leverages the expertise of both the Agrawal and Gounder research groups to tackle the challenges associated with producing SAF from light olefin gases. Light olefin gases can be derived either from shale gas hydrocarbon resources using CISTAR processes, or from carbon dioxide (CO2) as a feedstock using Susteon’s CO2-to-olefins catalyst technology with Joule heating being developed as part of this ARPA-E collaborative project.

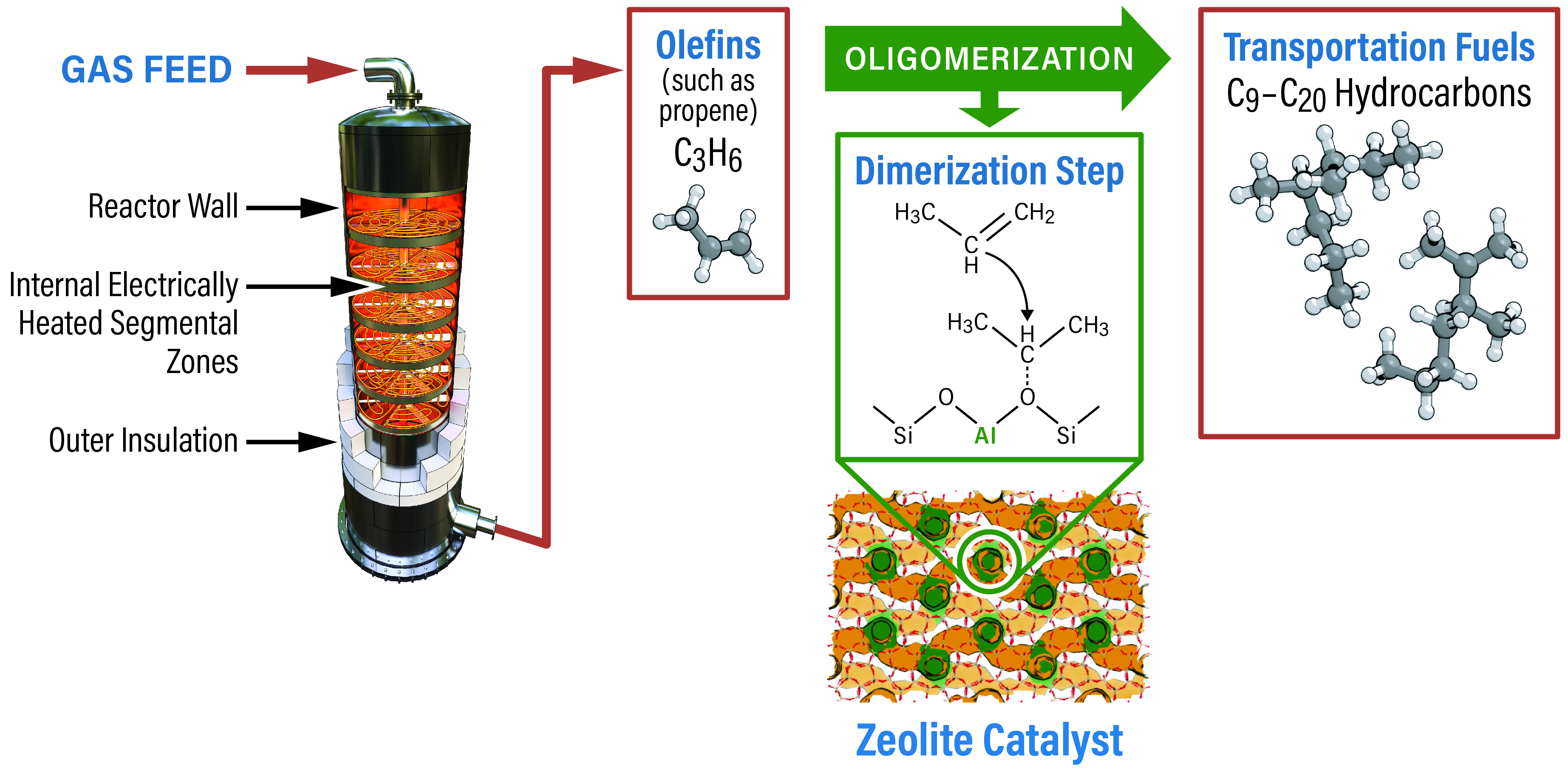

Professor Gounder’s research group has been instrumental in the design and development of advanced zeolite catalysts that significantly improve the production of SAF. These new patent-pending catalysts are designed to control oligomerization reactions, where light olefins are converted into heavier hydrocarbon liquids suitable for use as transportation fuels. The Gounder group’s zeolite catalysts offer superior control over product selectivity and extend the catalysts' operational lifespan. This innovation not only enhances the carbon and energy efficiency of SAF production but also reduces the overall cost by enabling new reactor and process designs that require lower capital investment.

Complementing Gounder’s catalyst development, Professor Agrawal’s research group is pioneering advancements in chemical reactor design. Traditional endothermic reactors, which convert ethane and propane into valuable olefins like ethylene and propylene, require high temperatures of 800°C to 900°C. These temperatures are typically achieved by burning fossil fuels, leading to substantial CO2 emissions. However, Agrawal’s team is reimagining these reactors by incorporating internal electrically heated elements. This innovative design dramatically improves heat transfer characteristics, resulting in more compact reactors with enhanced product yields.

The Agrawal group has further refined this technology by developing segmental heating zones within the reactors. Each segment can be independently controlled, allowing for precise regulation of the power supply based on the availability of renewable energy. This segmented approach optimizes effective reaction time within the reactor, ensuring consistent product quality even under variable power conditions. This flexibility is crucial for aligning chemical reactor operations with the intermittent nature of renewable energy sources.

Figure 2: Agrawal group has designed novel reactor configurations that are internally heated by using renewable electricity as shown in Figure 2.

The integrated application of novel catalyst and reactor designs developed at Purdue under the NSF CISTAR Engineering Research Center (ERC) will culminate in the successful demonstration of Susteon’s Electrified CO2 Hydrogenation-to-Olefins for Sustainable Aviation Fuel (ECHO-SAF) reactor.

Professor Fabio Ribeiro, CISTAR director, mentioned that "this collaboration between CISTAR and Susteon exemplifies the transformative potential of academic-industry partnerships in pioneering solutions to critical environmental challenges. The breakthrough advancements in catalyst development and reactor design emerging from this partnership are not only advancing the production of sustainable aviation fuel but also setting new benchmarks in efficiency and adaptability. These innovations are geared to play a key role in the broader mission of reducing carbon emissions and mitigating climate change."

The Center for Innovative and Strategic Transformation of Alkane Resources, CISTAR, is one of the flagship Engineering Research Centers (ERCs) funded by the National Science Foundation. ERCs bring together industry, academia, and government to cultivate engineering discovery and education in research areas critical to our nation’s strength. ERC’s infrastructure integrates four pillars: research, engineering workforce development, industry and innovation, and diversity & culture of inclusion, with industry partners being paramount to center success. CISTAR is a coalition of five collaborating institutions comprising of Purdue University, University of New Mexico, Northwestern University, University of Notre Dame, and The University of Texas at Austin.

Susteon, a pioneering technology startup located in the heart of Research Triangle, North Carolina, is at the forefront of developing and deploying revolutionary decarbonization technologies. The Susteon team has developed a portfolio of technologies tackling carbon capture, carbon utilization and hydrogen production. Susteon’s mission is to mitigate the impact of climate change and advance environmental sustainability by capturing and converting emissions into value at scale.