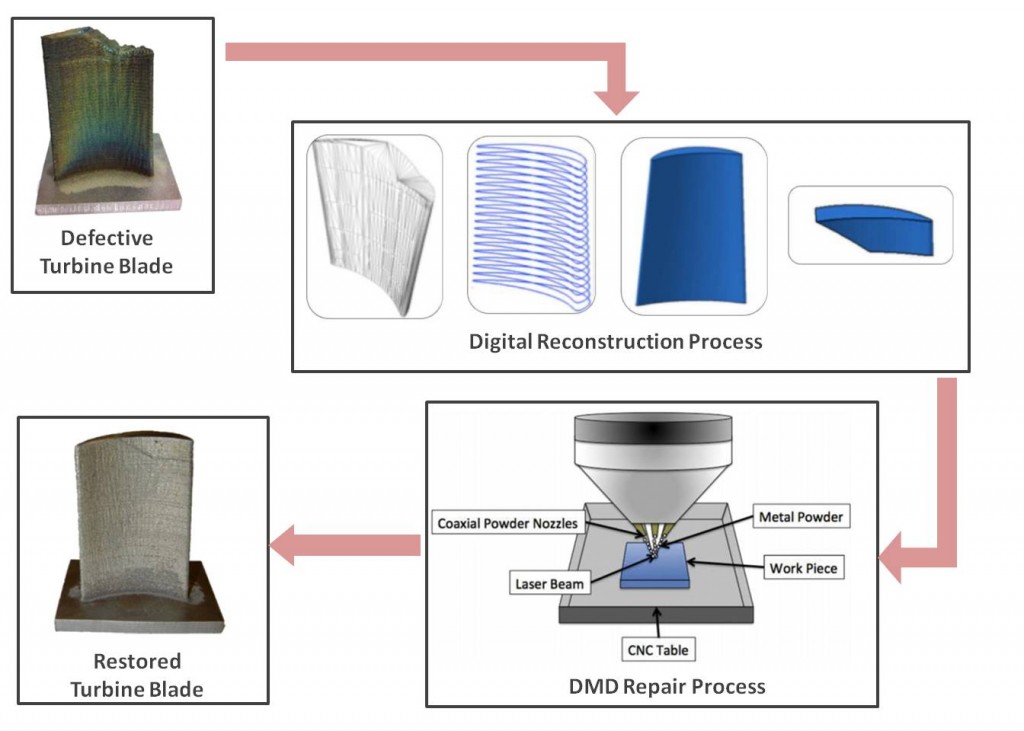

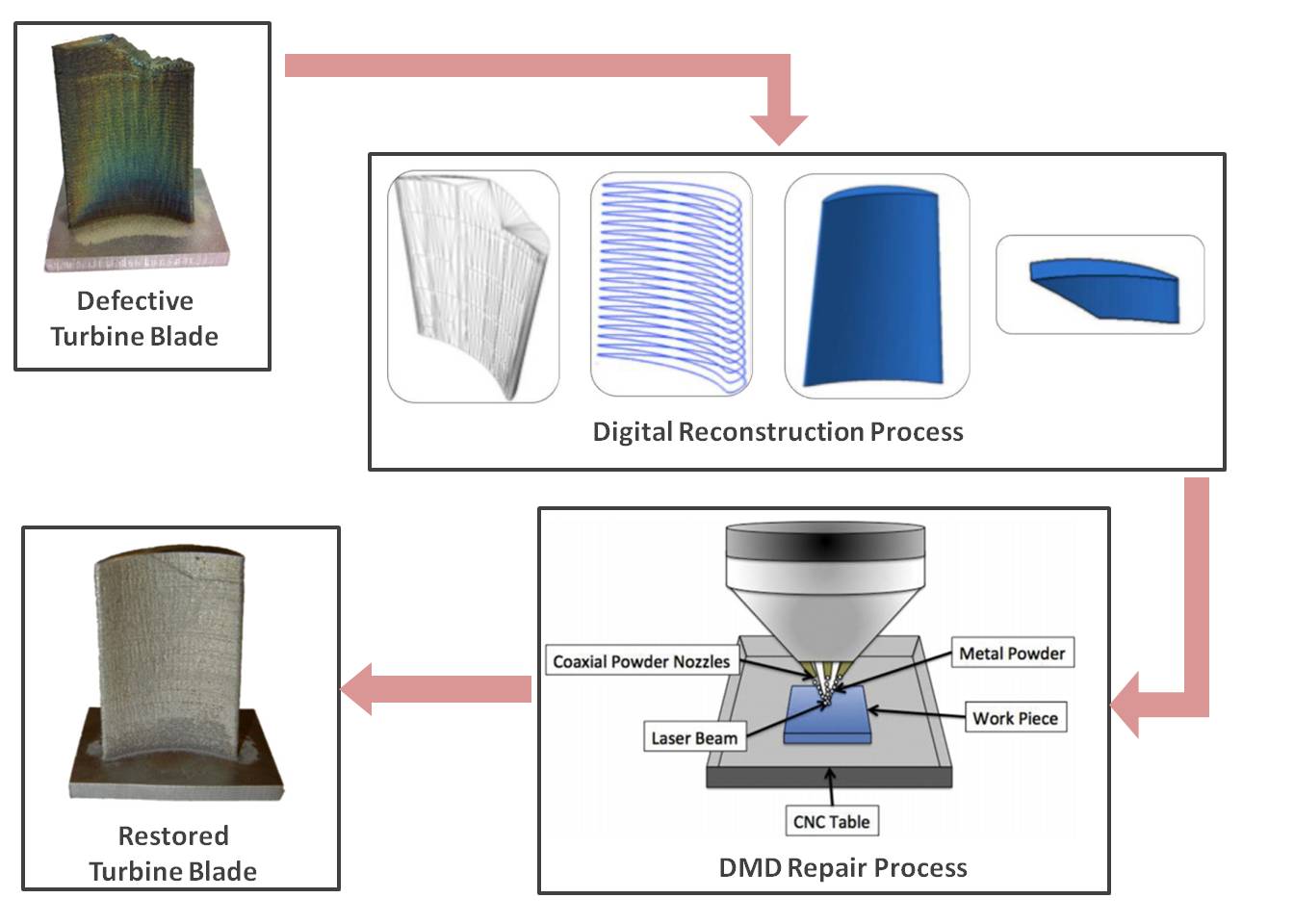

Laser direct deposition provides an attractive and cost effective means for repairing or remanufacturing high value engineering components. This study demonstrates the successful repair of defective voids in turbine airfoils based on a new semi-automated geometric reconstruction algorithm and a laser direct deposition process. A Boolean difference between the original defective model and the final reconstructed model yields a parameterized geometric representation of the repair volume. The experimental results of this method demonstrate the effectiveness of laser direct deposition in remanufacturing and its potential to adapt to a wide range of part defects. A Life Cycle Assessment (LCA) on the energy and environmental impacts by remanufacturing is also presented.

Remanufacturing of Turbine Blades by Laser Direct Deposition with Its Energy and Environmental Impact Analysis

Authors: J. Michael Wilson, Cecil Piya, Yung C. Shin, Fu Zhao, Karthik Ramani

Journal of Cleaner Production 80 (2014), 170 - 178

cecil

Cecil Piya is a PhD graduate from the school of Mechanical Engineering at Purdue University. Dr. Piya received his BSc in mechanical engineering from Worcester Polytechnic Institute, and earned his Doctorate at Purdue, while working as a graduate researcher in the C-Design Lab under Prof. Karthik Ramani. Here, his research explored novel Human-Computer Interactions and Digital Interfaces that leverage spatial gestures, tangible interactions, and pen-and-touch based media to support virtual 3D product design and shape modeling. In the past he also conducted research in areas such as digital shape reconstruction from 3D point clouds, geometric support for additive manufacturing, feature detection in 3D models, object identification in 2D images, and heat transfer.